Method and device for light, powder and gas coaxial transmission laser cladding forming manufacturing

A laser cladding, coaxial technology, used in manufacturing tools, laser welding equipment, coatings, etc., can solve the problems of powder beam collimation and rigidity need to be improved, the powder drop area is large, and the powder utilization rate is low. , to reduce the formation of unmelted particles, easy to adjust and control, and improve the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

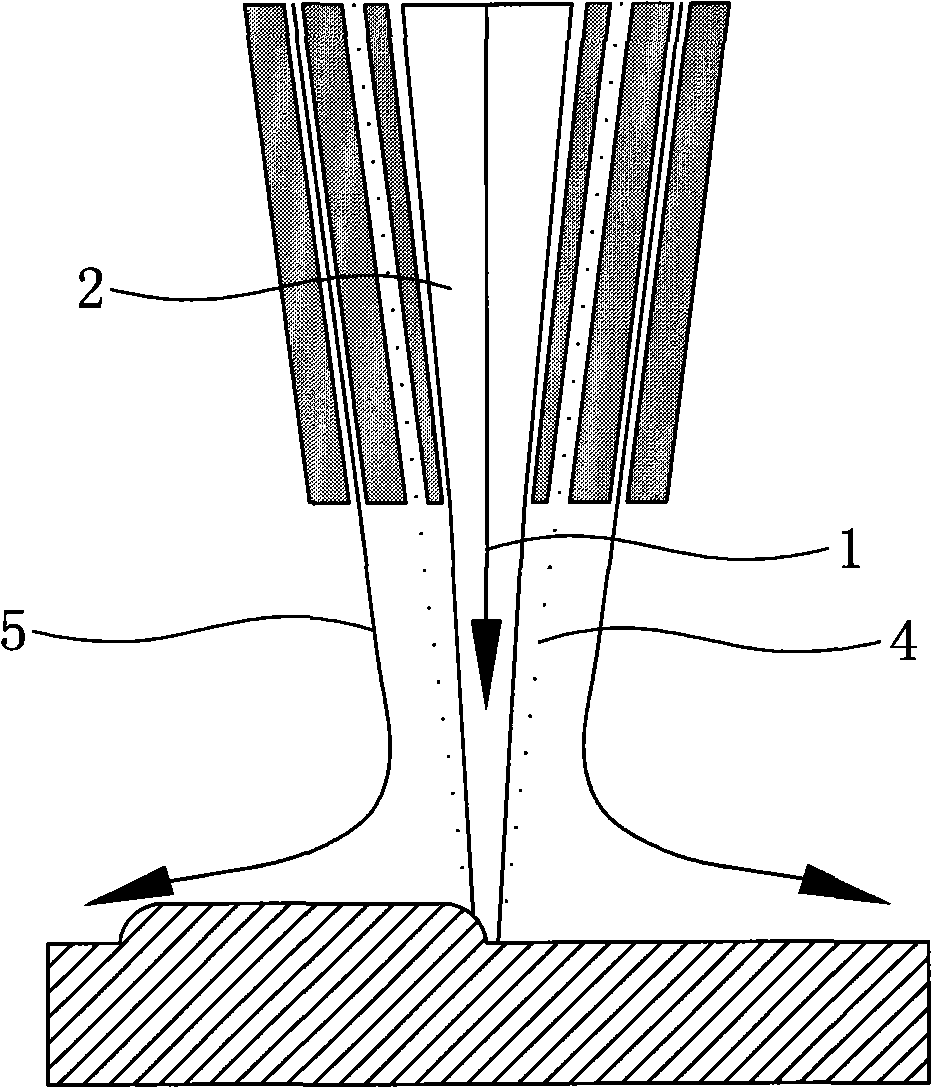

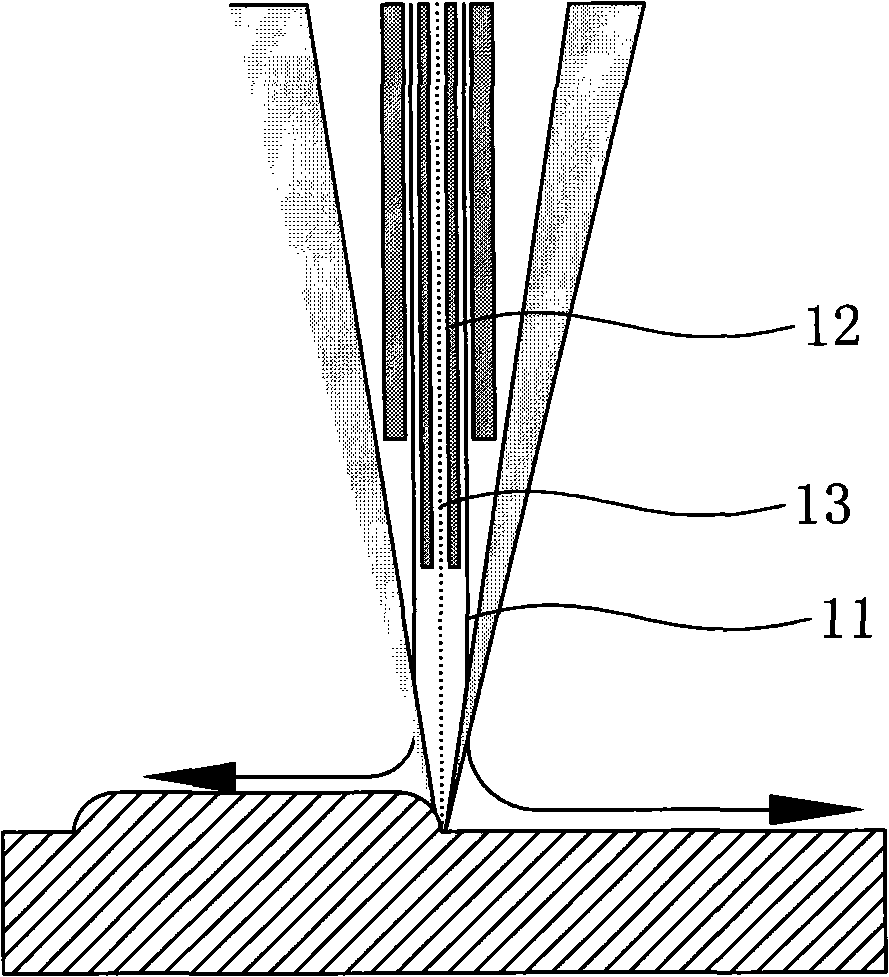

[0024] Embodiment one: see Figures 2 to 4 As shown, a laser cladding manufacturing method for coaxial transmission of light, powder and gas, transforms and expands the circular cross-section solid laser beam emitted by the laser through optical path conversion, and then becomes a circular laser beam. The circular laser beam is focused to become a hollow circular conical focused laser beam, and a powder spray nozzle is arranged in the hollow part of the circular conical focused laser beam, and the powder spray nozzle is coaxial with the circular conical focused laser beam line; a circle of collimated protective gas curtain is arranged on the periphery of the single powder beam ejected from the powder spray nozzle, and the collimated protective gas curtain is connected with the circular conical focused laser beam and the single powder beam sprayed from the powder spray nozzle. The air pressure of the collimated protective air curtain is 0.1-0.5Mpa.

[0025] A light, powder, an...

Embodiment 2

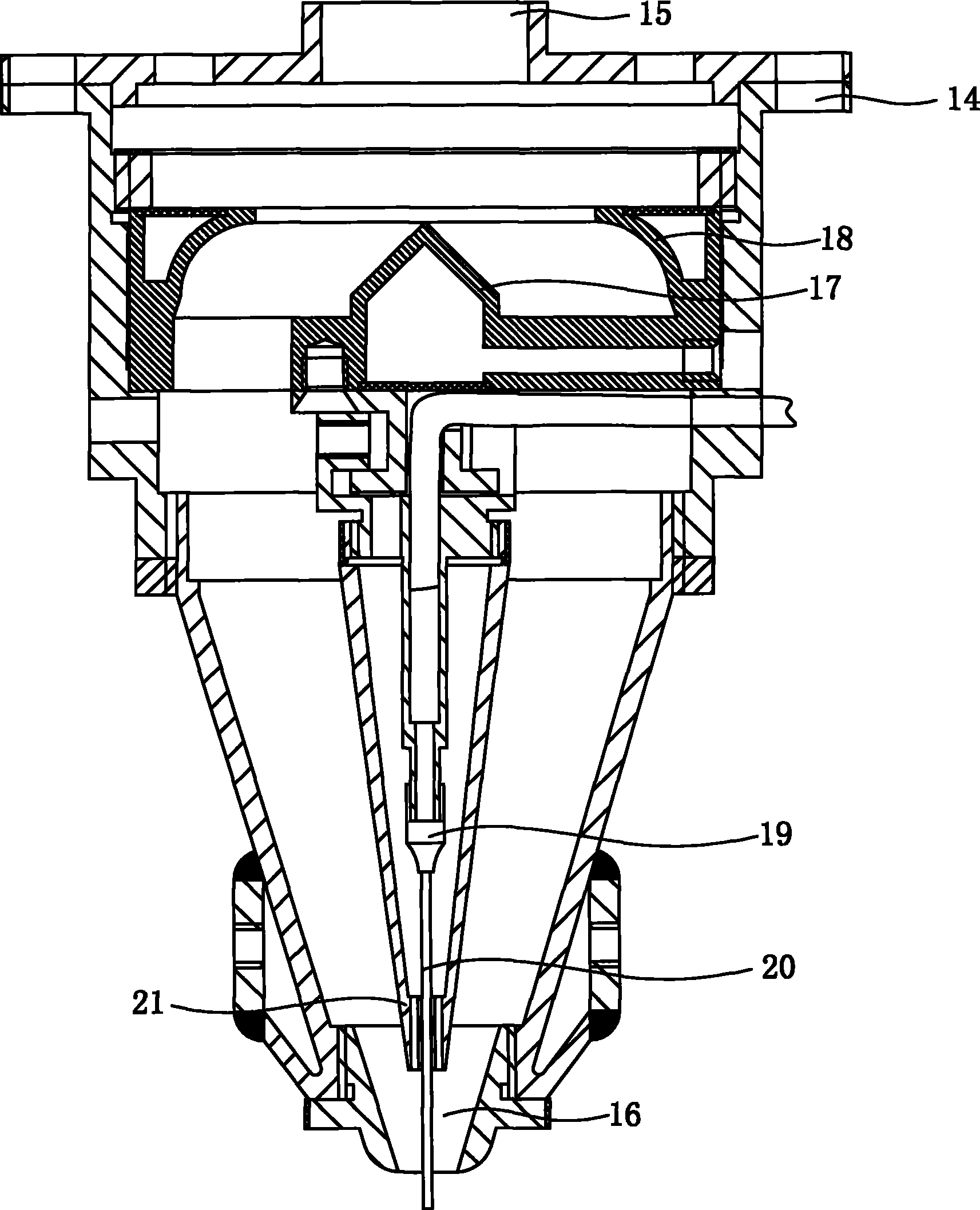

[0027] Embodiment two: see Figure 5 As shown, a device for coaxially conveying light, powder, and gas to laser cladding and forming manufacturing includes a powder feeding nozzle cylinder, a light inlet is opened on the top of the cylinder, and a light outlet is opened below the cylinder. There is a conical reflector facing the light entrance in the body, and a circular reflective focusing mirror is arranged coaxially with the conical reflector. A powder feeding tube is fixed below the conical reflector, and the lower end of the powder feeding tube is A powder spray nozzle 20 is provided, the powder spray nozzle is coaxial with the laser beam, and the outer periphery of the powder spray nozzle 20 is provided with a collimating protective air jacket 21 between the conical reflector and the exit of the powder spray nozzle 20. The collimation protection air jacket 21 is provided with three arc-shaped air outlets 22 along the circumferential direction. The axis of the powder spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com