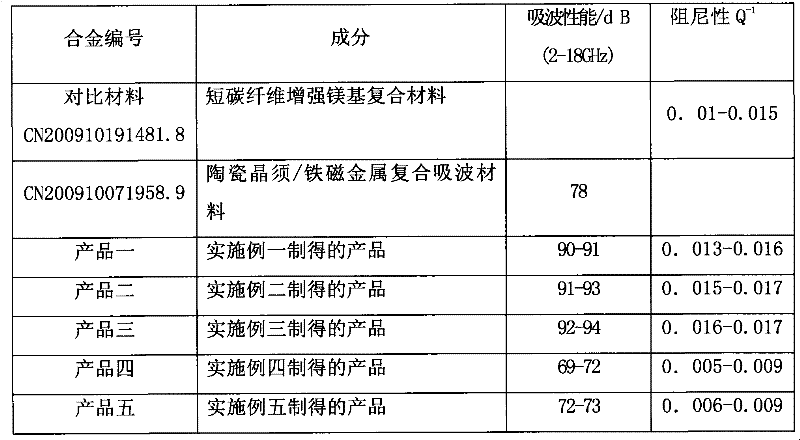

Aluminium alloys, pumice-ferric oxide and vermiculite-barium ferrate composite material and preparation method thereof

A technology of barium iron oxide and composite material, applied in the field of metal materials, can solve problems such as poor wave absorbing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The preparation process of the aluminum alloy base pumice iron oxide vermiculite barium iron oxide composite material of the present invention is as follows:

[0032] a. Preparation of Vermiculite Barium Iron Oxide Complex:

[0033] Dissolve ferric chloride, barium nitrate and citric acid in water at a ratio of 1:5:5 (just add a small amount of water to dissolve, also called solution), then put vermiculite into it, stir in a water bath at 80°C for 10 -20min, the size of the vermiculite particles is 0.1-0.3mm, the weight ratio of the three mixed solution to the vermiculite is 5:1, after the stirring is completed, the stirring material is placed in an oven at 120°C for 30min and cooled naturally, and then Put it in an oven at 560-570°C, keep it warm for 30 minutes, and then cool it down naturally to obtain the vermiculite barium iron oxide compound;

[0034] b. Preparation of pumice iron oxide complex:

[0035] Then put ferric chloride and ammonium ferrous sulfate into ...

Embodiment 2

[0040] Vermiculite iron oxide barium complex preparation: the weight ratio of ferric chloride, barium nitrate and citric acid in the solution is 1:10:20, the size of vermiculite particles is 0.5mm, and the weight ratio of solution and vermiculite is 10:1 ;

[0041] Pumice iron oxide complex preparation: the weight ratio of ferric chloride, ferrous ammonium sulfate and pumice in the solution is 1:1:2, and the size of the pumice particles is 1mm;

[0042] Composite preform preparation: the weight ratio of vermiculite barium iron oxide and pumice iron oxide composite is 1:2; the volume percentage of the composite preform in the composite material is controlled to be 50%;

[0043]The weight percentage of the aluminum alloy matrix components is 6% for Mg, 0.01% for Pb, 0.005% for Ta, 0.005% for Ga, 1% for Si and the rest is Al.

Embodiment 3

[0045] Vermiculite barium iron oxide complex preparation: the weight ratio of ferric chloride, barium nitrate and citric acid in the solution used is 1:7:10, the size of vermiculite particles is 0.3mm, and the weight ratio of solution and vermiculite is 7: 1;

[0046] Pumice iron oxide complex preparation: the weight ratio of ferric chloride, ammonium ferrous sulfate and pumice in the solution used is 1:1:1.5, and the size of pumice particles is 0.6-1mm;

[0047] Composite preform preparation: the weight ratio of vermiculite barium iron oxide and pumice iron oxide composite is 1:1.5; the volume percentage of the control composite prefabricated accounted for composite material is 40%;

[0048] The weight percent content of the aluminum alloy liquid is 4% for Mg, 0.008% for Pb, 0.003% for Ta, 0.003% for Ga, 0.5%-1% for Si, and the rest is Al.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com