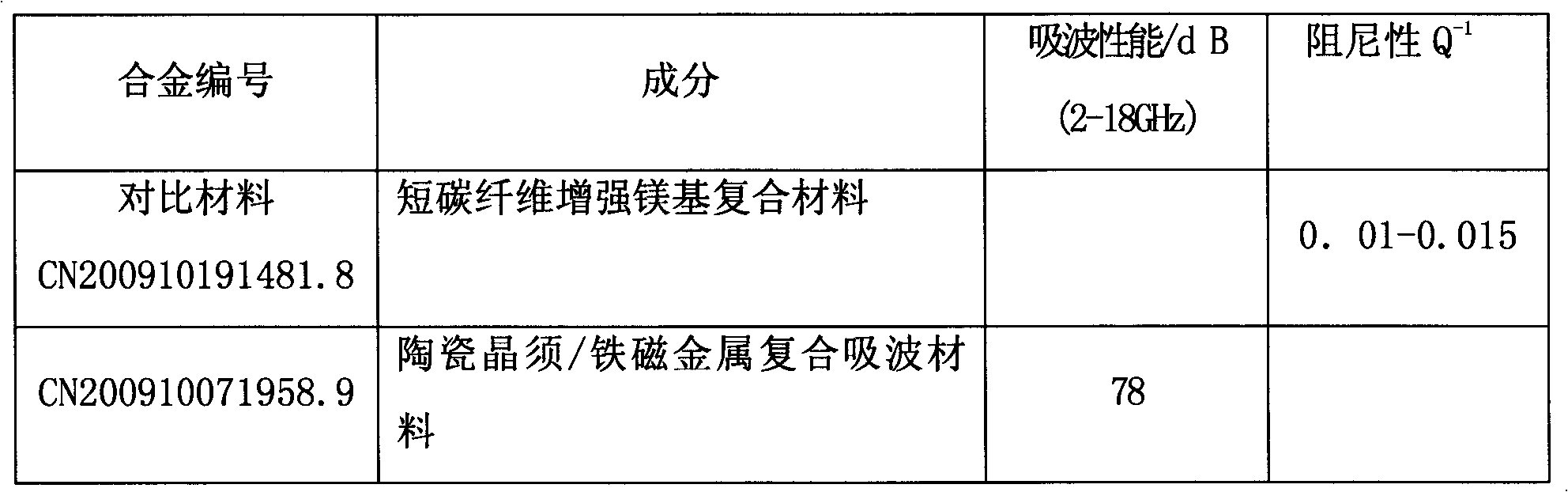

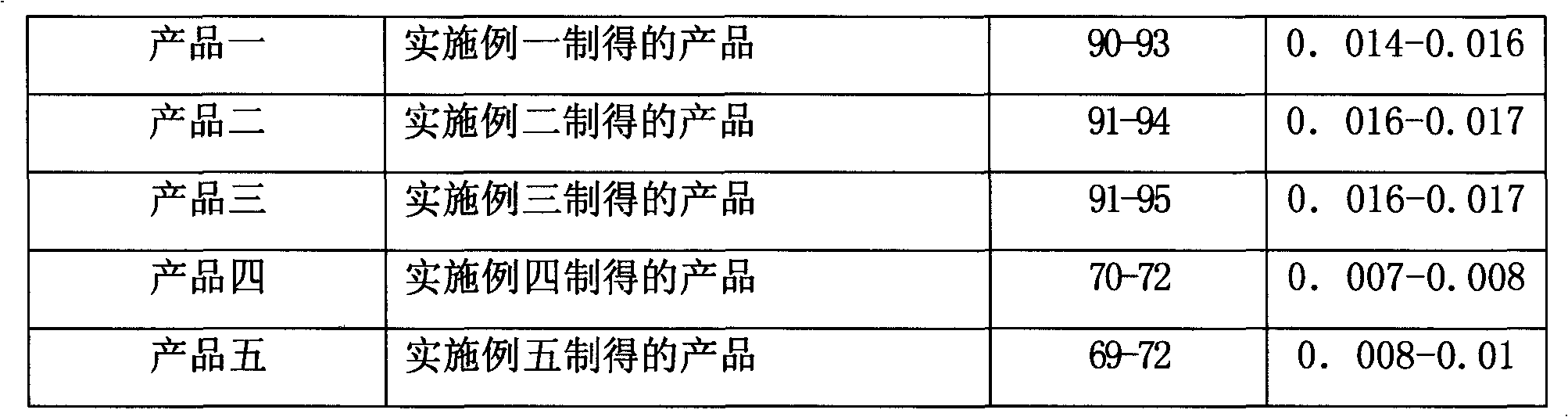

Magnesium-base copper-fiber pumice iron-barium oxide composite and preparation method thereof

A technology of barium iron oxide and composite materials, applied in the field of metal materials, can solve problems such as poor microwave absorption performance and complicated process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The preparation process of the magnesium-based copper fiber pumice barium iron oxide composite material of the present invention is as follows:

[0035] a. Preparation of pumice iron oxide barium complex:

[0036] 1. Add a small amount of water to dissolve ferric chloride, barium nitrate and citric acid in a ratio of 1:5:5 to form a mixed solution of the three, then put in pumice stone, stir in a water bath of 80 for 10-20min, the size of the pumice stone particles It is about 0.5mm, and the weight ratio of the mixed solution of the three and the pumice is 5:1. After stirring, the agitated material is placed in an oven at 120 ° C for 30 minutes, and then cooled naturally, and then placed in an oven at 550-590 ° C. Natural cooling after 30min of insulation to obtain pumice iron barium oxide complex;

[0037] 2. Then put the ferric chloride and ferrous ammonium sulfate into the hydrothermal container with teflon lining, add water to dissolve (add a small amount of water ...

Embodiment 2

[0043] a. Preparation of pumice iron oxide barium complex:

[0044] The weight ratio of ferric chloride, barium nitrate and citric acid solution is 1:10:20, the weight ratio of this solution and pumice stone is 10:1, and the size of the pumice stone is 1 mm. In the preparation of the pumice iron barium oxide composite, the weight ratio of ferric chloride, ferrous ammonium sulfate and the pumice barium oxide composite is 1:1:2.

[0045] b. Preparation of copper alloy fiber: Mn is 8% by weight, Al is 0.009%, and the rest is made of Cu.

[0046] c. Control the composite preform to account for 45% of the cavity volume of the metal mold;

[0047] d. Preparation of magnesium alloy liquid: the weight percentage of magnesium alloy components is 6% Al, 0.01% Pb, 0.005% Ta, 1% Si, 0.01% Te, and the rest is Mg.

Embodiment 3

[0049] a. Preparation of pumice iron oxide barium complex:

[0050] The weight ratio of ferric chloride, barium nitrate and citric acid solution is 1:8:10, the weight ratio of this solution and pumice stone is 8:1, and the size of the pumice stone is 0.7 mm. In the preparation of the pumice iron barium oxide composite, the weight ratio of ferric chloride, ferrous ammonium sulfate and the pumice barium oxide composite is 1:1:1.5.

[0051] b. Preparation of copper alloy fiber: Mn is 10% by weight, Al is 0.006%, and the rest is made of Cu.

[0052] c. Control the composite preform to account for 50% of the cavity volume of the metal mold;

[0053] d. Preparation of magnesium alloy liquid: the weight percentage of magnesium alloy components is 4% Al, 0.007% Pb, 0.003% Ta, 0.8% Si, 0.007% Te, and the rest is Mg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com