Process and apparatus for low oxygen and low moistness packing

A low-humidity, confined space technology, applied in packaging, electrical components, semiconductor/solid-state device manufacturing, etc., can solve the problems of functional failure, separation, insufficient and good welding area of preserved objects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

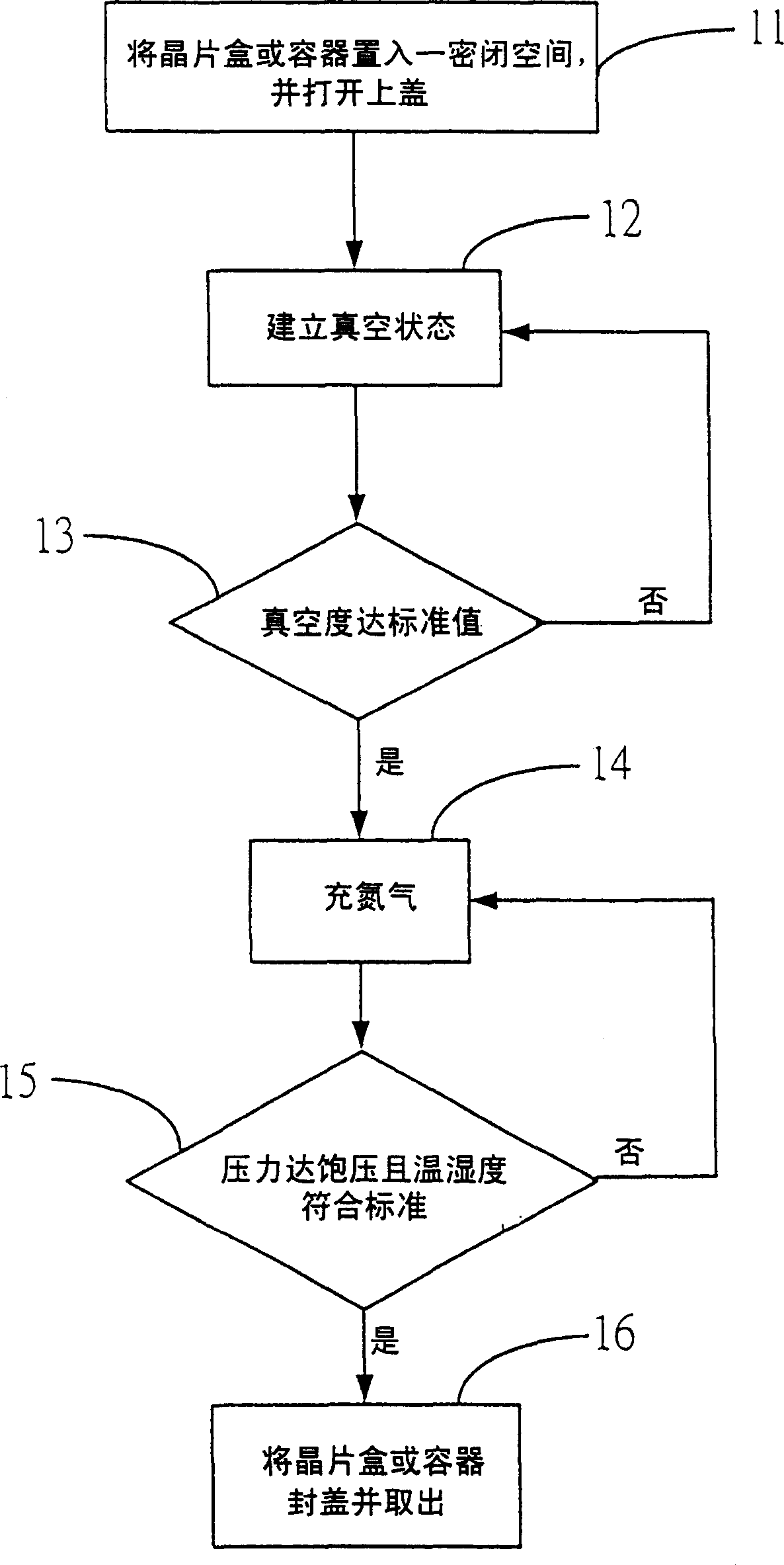

[0028] figure 1 It is a working flow diagram of the low oxygen and low humidity sequestration method of the present invention. According to step 11, put a wafer box loaded with wafers or a container for storing articles into a closed space, it is worth noting that the upper cover of the wafer box or container must be opened, so that the wafer box or container and the inside of the closed space Gases can be exchanged freely. After confirming that the airtightness of the confined space is correct, the vacuum state is established, as in step 12. Generally, the negative pressure reaches about 6 atmospheres, which means that the vacuum degree has met the operating standard, as in step 13. If the degree of vacuum is insufficient, it is necessary to continue to remove the remaining air in the confined space, otherwise, enter the next step 14 to perform nitrogen filling. In this step, nitrogen with a purity of more than 99% is poured into the confined space to fill the entire space ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com