Ceramic slurry for aluminizing protection and preparation method and application of ceramic slurry

A ceramic slurry and aluminizing technology, which is applied in transportation and packaging, metal processing equipment, metal material coating technology, etc., can solve the problems of high toxicity, cumbersome operation, and increased cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1) Slurry configuration

[0043] The mass ratio of zirconia, binder and metal is 2.5:1:1. The binder is prepared by dissolving 3g of polyvinyl acetate in 20mL of acetone, and the metal is pure nickel powder with a purity ≥ 99.2% and a particle size ≤ 150 μm. The preparation method of the above-mentioned ceramic slurry for aluminizing protection is as follows: firstly mix zirconia powder and binder in a mass ratio of 2.5:1, then add metallic nickel powder and stir evenly to obtain the ceramic slurry for aluminizing protection.

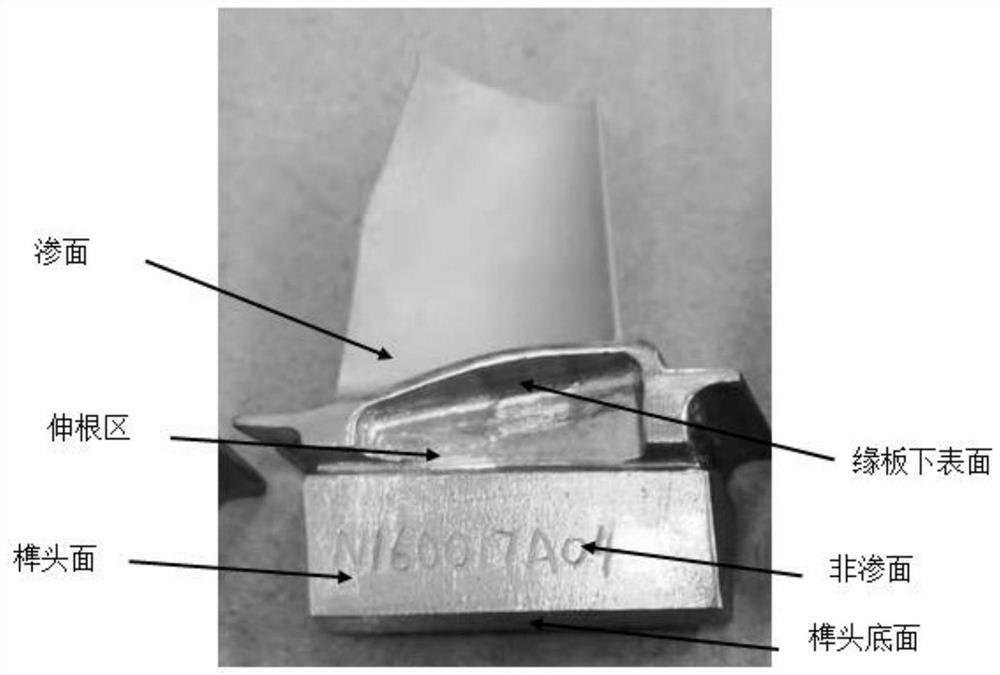

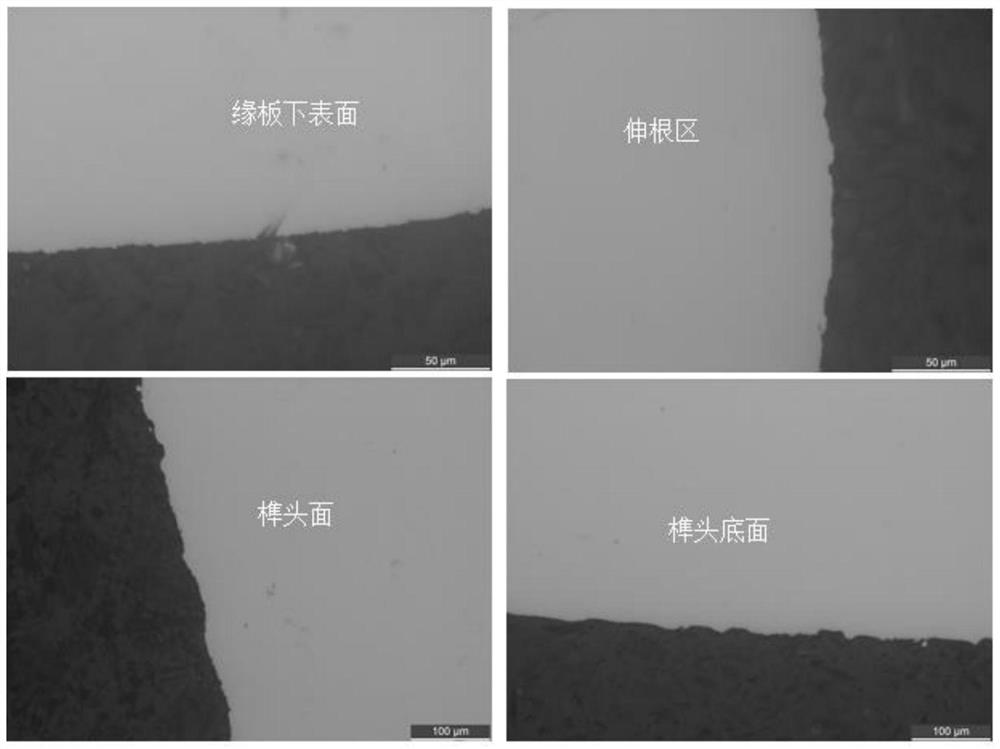

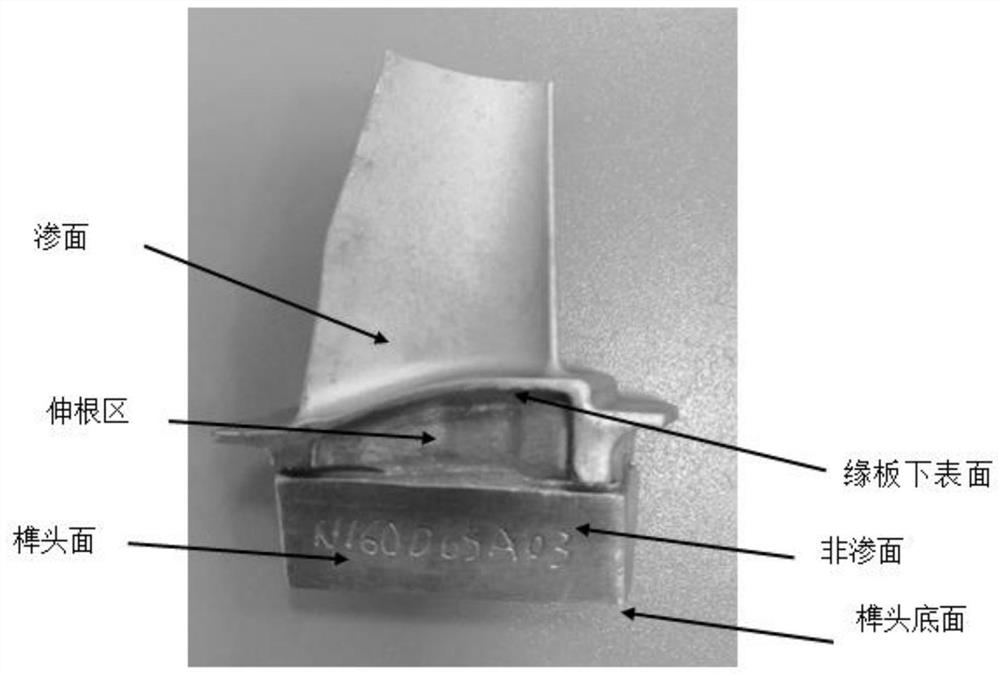

[0045] The prepared ceramic slurry for aluminizing protection is directly coated on the tenon of the turbine blade, and a total of 3 layers are coated. The specific steps of coating are: coating the first layer and then drying, and then coating the second layer; After one layer dries, the next layer can be applied. In order to prevent delamination of ceramic slurry for aluminizing protection, constant stirring is r...

Embodiment 2

[0050] (1) Slurry configuration

[0051] The mass ratio of zirconia, binder and metal powder is 2.5:1:1. The binder is prepared by dissolving 3g of polyvinyl acetate in 20mL of acetone, and the metal is pure chromium powder with a purity ≥ 99.5% and a particle size ≤ 150 μm. The preparation method of the above-mentioned ceramic slurry for aluminizing protection is as follows: firstly mix zirconia powder and binder at a mass ratio of 2.5:1, then add metal chromium powder and stir evenly to obtain the ceramic slurry for aluminizing protection.

[0052] (2) Slurry coating

[0053] The prepared ceramic slurry for aluminizing protection is directly coated on the tenon of the turbine blade, and a total of 5 layers are coated. The specific steps of coating are: coating the first layer and then drying, and then coating the second layer; After one layer dries, the next layer can be applied. In order to prevent delamination of the ceramic slurry for aluminizing protection, the coatin...

Embodiment 3

[0058] (1) Slurry configuration:

[0059] The mass ratio of zirconia, binder and metal powder is 2.5:1:1. The binder is prepared by dissolving 3 g of polyvinyl acetate in 20 mL of acetone, and the metal is pure Fe powder with a purity ≥ 99.8% and a particle size ≤ 150 μm. The preparation method of the above-mentioned ceramic slurry for aluminizing protection is as follows: firstly mix zirconia powder and binder at a mass ratio of 2.5:1, then add metallic iron powder and stir evenly to obtain the ceramic slurry for aluminizing protection.

[0060] (2) Slurry coating:

[0061] The prepared ceramic slurry for aluminizing protection is directly coated on the tenon of the turbine blade, and a total of 7 layers are coated. The specific steps of coating are: coating the first layer and then drying, and then coating the second layer; After one layer dries, the next layer can be applied. In order to prevent delamination of the ceramic slurry for aluminizing protection, the coating n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com