Preparation method and application of strontium perovskite catalytic cathode

A perovskite and catalytic electrode technology, which is applied in the field of preparation of strontium-based perovskite catalytic cathodes, can solve the problems of high cost and insufficient stability, and achieve the effects of low production cost, favorable electrical conductivity, and stable operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

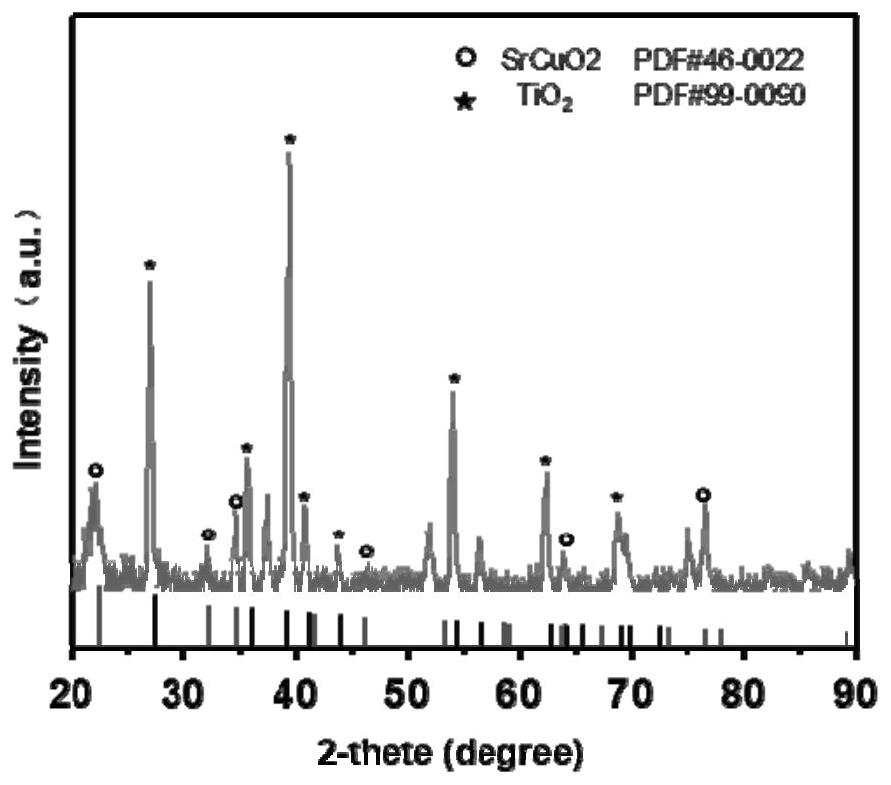

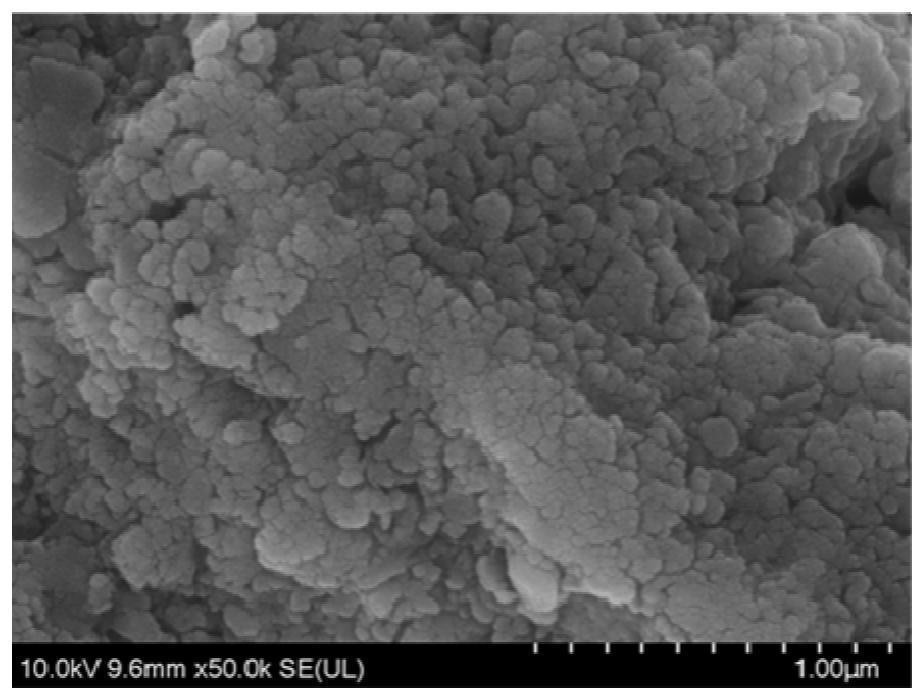

[0042] Embodiment 1: comprise the following steps:

[0043] S1: the Cu(NO 3 ) 2 ·6H 2 O and Sr(NO 3 ) 2 Dissolve in 25ml of water according to the metal ion ratio of 1:1, where Cu(NO 3 ) 2 ·6H 2 O concentration is 0.25mol / L, Sr(NO 3 ) 2 The concentration is 0.25mol / L; dissolve 6.02g of sodium citrate monohydrate in 25ml of water, and mix the two solutions to make a total of 50mL of mixed solution, slowly add 6.9ml of ethylene glycol solution, stir slowly, and keep warm at 80°C for 10h , evaporated to dryness, is the gel;

[0044] S2: Cut the porous titanium sheet electrode to 3cm*3cm*2mm, soak it in 10% oxalic acid solution at 100°C, pickle it for 1 hour, and ultrasonicate until the solution becomes clear, which is the pretreated porous titanium sheet electrode;

[0045] S3: Soak the pretreated porous titanium sheet electrode in the gel until no bubbles are generated for 5 minutes;

[0046] S4: Dry the soaked porous titanium sheet electrode at 80°C for 20 minutes, t...

Embodiment 2

[0048] Embodiment 2: comprise the following steps:

[0049] S1: Fe(NO 3 ) 2 and Sr(NO 3 ) 2 Dissolve in 25ml of water according to the metal ion ratio of 1:1, in which Fe(NO 3 ) 2 Concentration is 0.25mol / L, Sr(NO 3 ) 2 The concentration is 0.25mol / L; dissolve 6.02g of sodium citrate monohydrate in 25ml of water, and mix the two solutions to make a total of 50mL of mixed solution, slowly add 6.9ml of ethylene glycol solution, stir slowly, and keep warm at 80°C for 10h , evaporated to dryness, is the gel;

[0050] S2: Cut the porous titanium sheet electrode to 3cm*3cm*2mm, soak it in 10% oxalic acid solution at 100°C, pickle it for 1 hour, and ultrasonicate until the solution becomes clear, which is the pretreated porous titanium sheet electrode;

[0051] S3: Soak the pretreated porous titanium sheet electrode in the gel until no bubbles are generated for 5 minutes;

[0052] S4: Dry the soaked porous titanium sheet electrode at 80°C for 20 minutes, then place it at 700...

Embodiment 3

[0054] Embodiment 3: comprise the following steps

[0055] S1: Co(NO 3 ) 2 ·6H 2 O and Sr(NO 3 ) 2 Dissolve in 25ml of water according to the metal ion ratio of 1:1, where Co(NO 3 ) 2 ·6H 2 O concentration is 0.25mol / L, Sr(NO 3 ) 2 The concentration is 0.25mol / L; dissolve 6.02g of sodium citrate monohydrate in 25ml of water, and mix the two solutions to make a total of 50mL of mixed solution, slowly add 6.9ml of ethylene glycol solution, stir slowly, and keep warm at 80°C for 10h , evaporated to dryness, is the gel;

[0056] S2: Cut the porous titanium sheet electrode to 3cm*3cm*2mm, soak it in 10% oxalic acid solution at 100°C, pickle it for 1 hour, and ultrasonicate until the solution becomes clear, which is the pretreated porous titanium sheet electrode;

[0057] S3: Soak the pretreated porous titanium sheet electrode in the gel until no bubbles are generated for 5 minutes;

[0058] S4: Dry the soaked porous titanium sheet electrode at 80°C for 20 minutes, then p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com