Magnesium alloy pumice ferric oxide cobalt composite material and preparation method thereof

A technology of composite material and iron oxide, which is applied in the field of magnesium alloy pumice iron oxide cobalt wave-absorbing and vibration-absorbing composite material and its preparation method and its preparation field, which can solve the problems of poor wave-absorbing performance and complicated process, and achieve the effect of enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

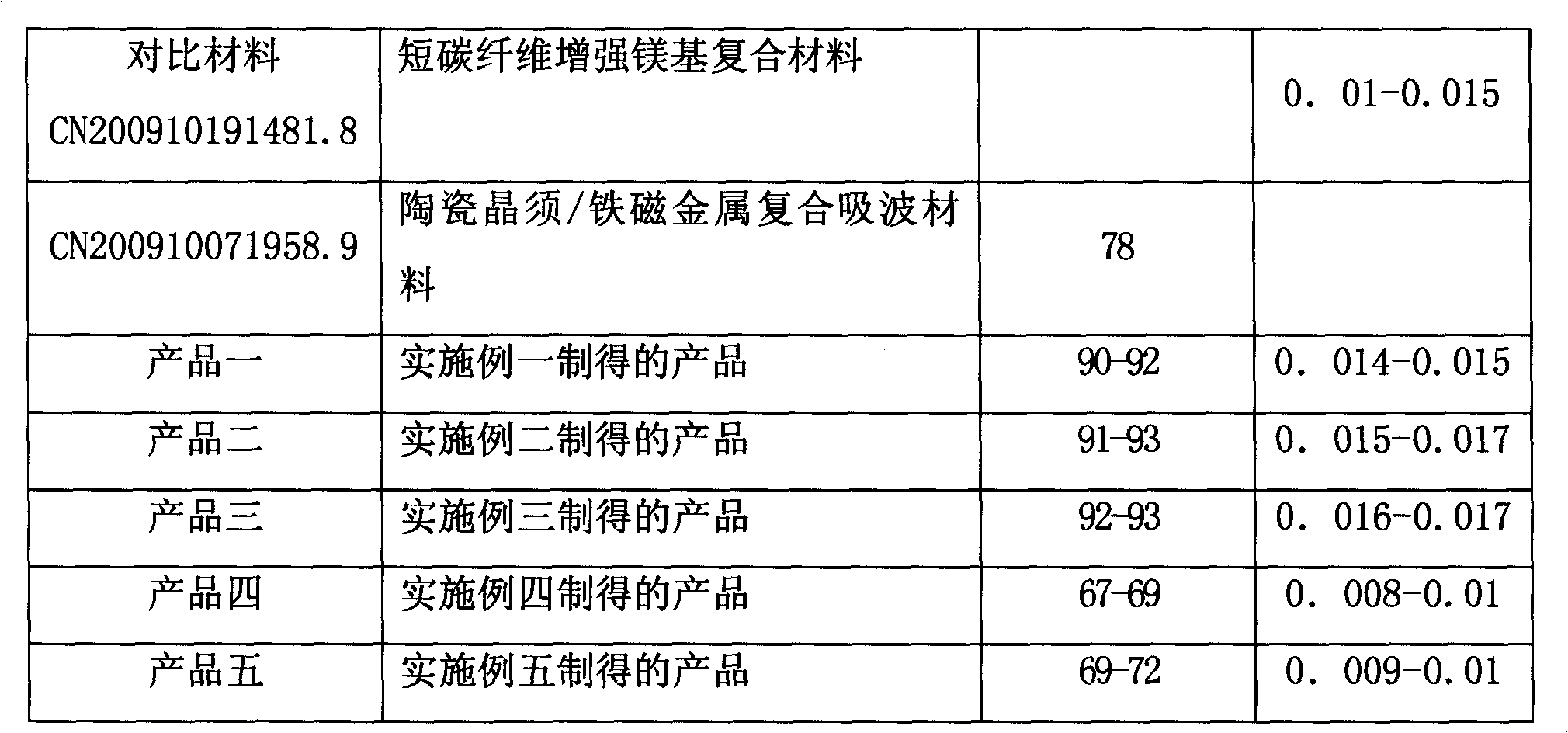

Examples

Embodiment 1

[0028] The preparation process of magnesium alloy base pumice iron oxide cobalt composite material of the present invention is as follows:

[0029] a. Preparation of pumice iron oxide cobalt compound: put ferric chloride, cobalt chloride and ferrous ammonium sulfate into a hydrothermal container with Teflon lining, add water to dissolve, and then load pumice, the size of pumice particles It is about 0.5mm. Stir the above three substances for 2-7min. The weight ratio of the four substances, ferric chloride, cobalt chloride, ferrous ammonium sulfate and pumice, is 1:1:1:1. After heat preservation in an oven at 220°C for 3 hours, cool naturally to obtain the pumice iron oxide cobalt compound;

[0030] Then dolomite and pumice iron oxide cobalt compound are mixed, the size of dolomite particle is about 0.01mm, the weight ratio of pumice iron oxide cobalt compound and dolomite is 1: 0.05, the mixture of dolomite and pumice iron oxide cobalt compound Put it into the cavity of a ste...

Embodiment 2

[0034] a. Preparation of the pumice iron oxide-cobalt complex: when forming the pumice iron oxide-cobalt complex, the weight ratio of ferric chloride, cobalt chloride, ferrous ammonium sulfate and pumice is 1:2:1:2. The pumice particle size is about 1mm.

[0035] Composite preform: in the mixture of dolomite and pumice iron oxide cobalt compound, the weight ratio of pumice iron oxide cobalt compound to dolomite is 1:0.09, and the size of dolomite particles is 0.06mm; control the pumice iron oxide cobalt compound The volume percentage of the composite material is 40%;

[0036] B, the preparation of magnesium alloy liquid: the weight percent of the chemical composition of this magnesium alloy substrate: Al is 8%, Th is 0.05%, Si is 1%, Bi is 0.005%;

[0037] Its preparation process is with embodiment one.

Embodiment 3

[0039] a. Preparation of the pumice iron oxide-cobalt complex: when forming the pumice iron oxide-cobalt complex, the weight ratio of ferric chloride, cobalt chloride, ferrous ammonium sulfate and pumice is 1:1.2:1:1.2. The pumice particle size is about 0.6mm.

[0040]Composite preform: in the mixture of dolomite and pumice iron oxide cobalt compound, the weight ratio of pumice iron oxide cobalt compound to dolomite is 1:0.07, and the size of dolomite particles is 0.05mm; control the pumice iron oxide cobalt compound The volume percentage of the composite material is 43%;

[0041] B, the preparation of magnesium alloy liquid: the weight percent of the chemical composition of this magnesium alloy substrate: Al is 6%, Th is 0.04%, Si is 0.7%, Bi is 0.003%;

[0042] Its preparation process is with embodiment one.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com