Ashing method for photoresist patterns

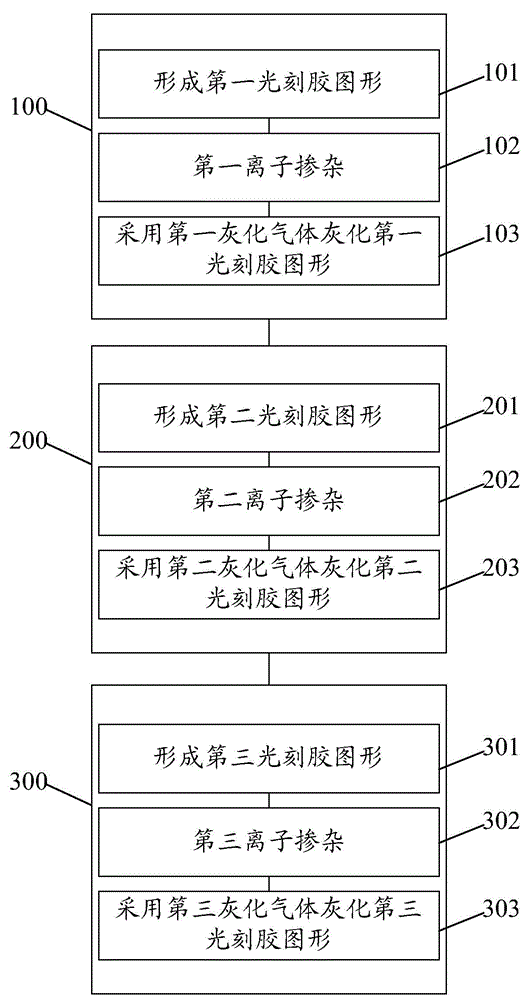

A photoresist and ashing technology, applied in the processing of photosensitive materials, etc., can solve the problems of low ashing efficiency, wafer output, impact, ion distribution changes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The existing ashing process easily affects the substrate when ashing the photoresist pattern. For example, the oxidation of some oxygen-containing plasmas in the existing ashing process is likely to affect the substrate of silicon material and the gates that may be contained in the substrate, and these ashing gases are also likely to cause mechanical damage to the substrate. permanent damage and form recesses in the substrate, the recesses will affect the progress of subsequent process steps and the electrical performance of the formed semiconductor device.

[0041] The existing ashing process may also affect the distribution of dopant ions in the doped regions already formed in the substrate, for example, cause the concentration of dopant ions in the doped regions to change.

[0042] Part of the dopant ions will also enter the photoresist pattern while ion doping a specific region of the substrate, so after the doping is completed, the photoresist pattern will also con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com