Flowing atmosphere edge-defined film-fed crystal growth multi-chip sapphire crystal growth device and method

A technology of guided mode method and sapphire, which is applied in the field of multi-chip sapphire guided mode crystal growth device, which can solve the problems of static protective atmosphere, poor product consistency, and long delivery cycle, so as to achieve visible and controllable growth process, guarantee The effect of growing crystal feeding amount and increasing feeding intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

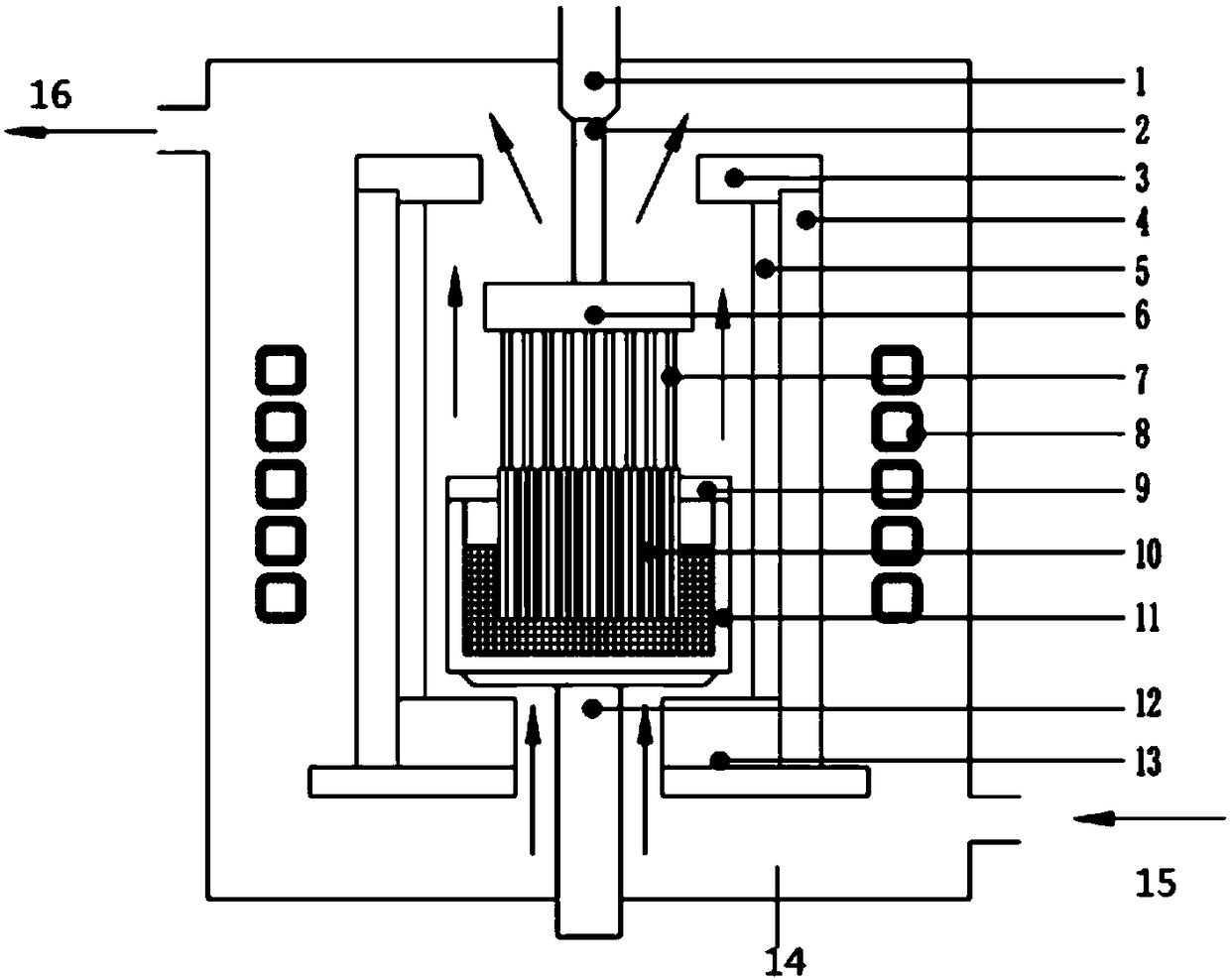

[0042] Such as figure 1 As shown, a multi-chip sapphire crystal growth device of the flowing atmosphere guided mode method includes a melting furnace and an atmosphere device, wherein the atmosphere device 14 is a sealed chamber with good airtightness, and an air inlet 15 is provided at one corner of the bottom, and the upper part Diagonal position is provided with gas outlet 16, and described melting furnace is placed in atmosphere device 14, and in the atmosphere device 14, input flow direction is the inert gas that enters from bottom to top, and described melting furnace includes tray, is arranged on the tray The insulation cylinder 4, the induction coil 8 set on the insulation cylinder 4, the bottom insulation layer 13, the crucible 11, the growth mold unit 10, the seed crystal 6 and the seed crystal rod 1 arranged in the insulation cylinder 4 in sequence from bottom to top , the side wall of the heat preservation tube 4 is provided with a heating element 5, and the seed c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com