Method for producing porous ceramic materials by adopting low-temperature hydrothermal method

A technology of porous ceramics and hydrothermal method, which is applied in the direction of ceramic products, applications, household appliances, etc., can solve the problems of lowering the liquid phase point of sintering aids, increasing the difficulty of manufacturing precision ceramic parts, and reducing the mechanical properties of porous materials, etc., to achieve water The effect of low heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

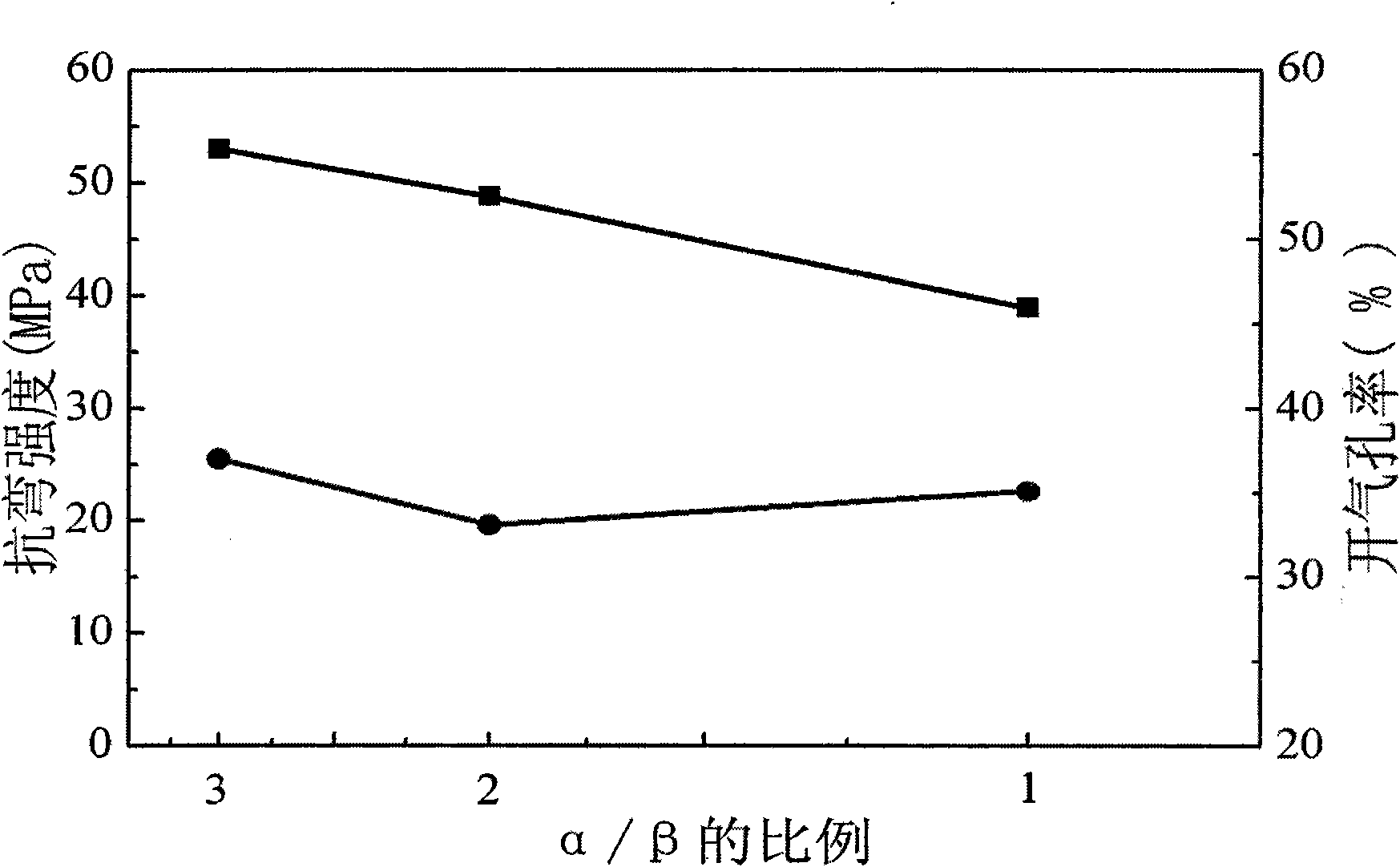

[0042] In the preparation method of the present invention, ceramic porous materials with different porosities and strengths can be prepared by adjusting technological conditions such as sol concentration, hydrothermal conditions, and particle gradation of ceramic powder in the molded body.

[0043] The porosity of the porous ceramic material prepared by the invention is 30-50%.

[0044] The bending strength of the porous ceramic material prepared by the invention is 20-80MPa.

[0045] The dielectric constant of the porous ceramic material prepared by the invention is 3.2-3.8.

Embodiment 1

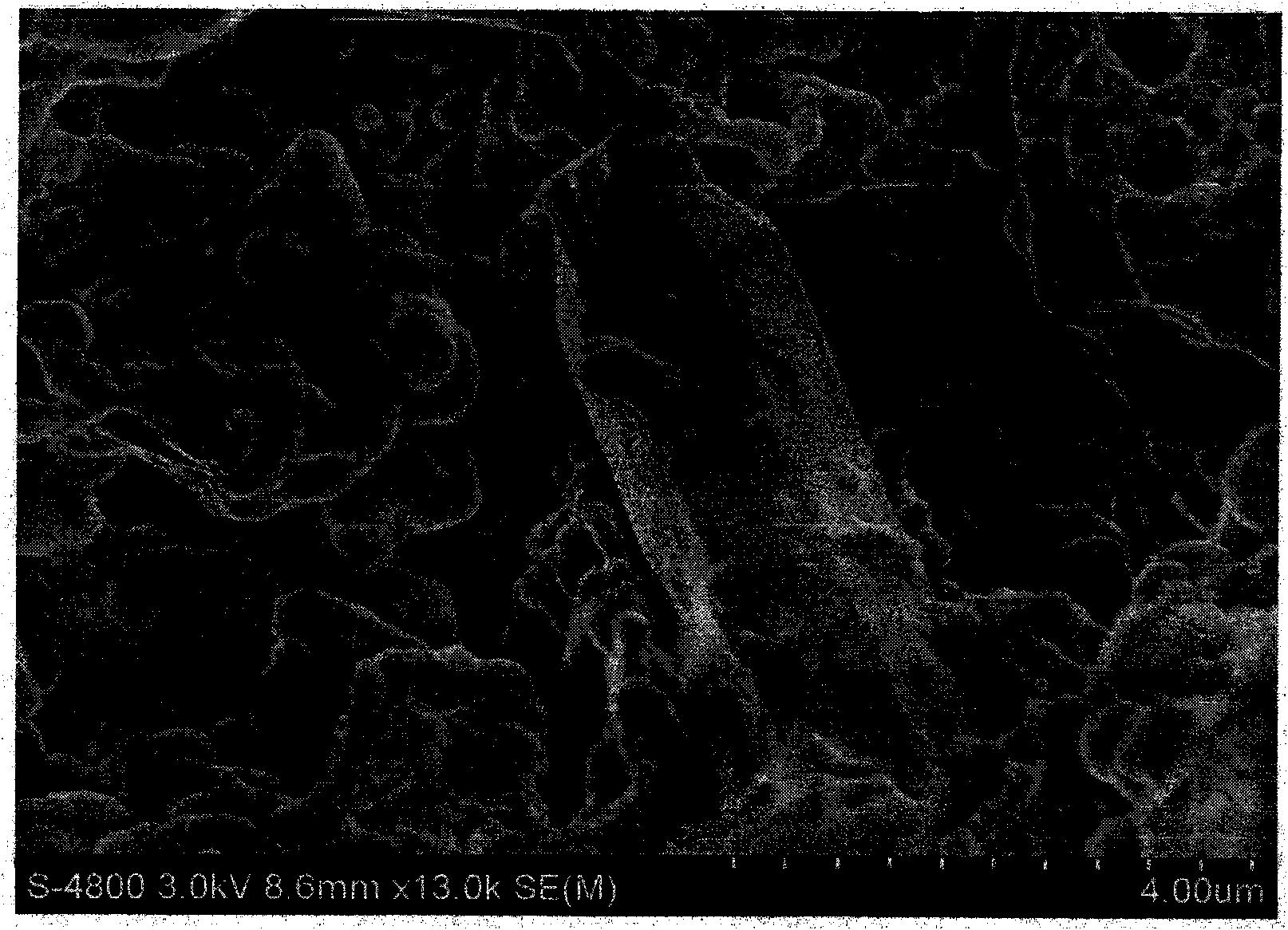

[0047] Low-temperature hydrothermal preparation of silicon nitride porous material with a porosity of 45% has the following steps:

[0048] The first step: preparation of ceramic molded body

[0049] First, mix evenly α-silicon nitride powder with a median particle size of 0.5 μm, β-silicon nitride powder with a median particle size of 11 μm, and deionized water to prepare the first intermediate;

[0050] Adding ammonia water with a concentration of 2 mol / L to the first intermediate to adjust the pH of the first intermediate to 9, thereby preparing the second intermediate;

[0051] Add acrylic acid amine to the second intermediate and make the third intermediate after ball milling for 120 minutes; the ball milling speed is 300r / min;

[0052] Add silica sol to the third intermediate, stir and degas under vacuum, inject into the mold, put it into a drying temperature of 80±5°C, dry for 30 minutes, and demould to obtain a ceramic molded body;

[0053] Dosage: Add 130g of α-sili...

Embodiment 2

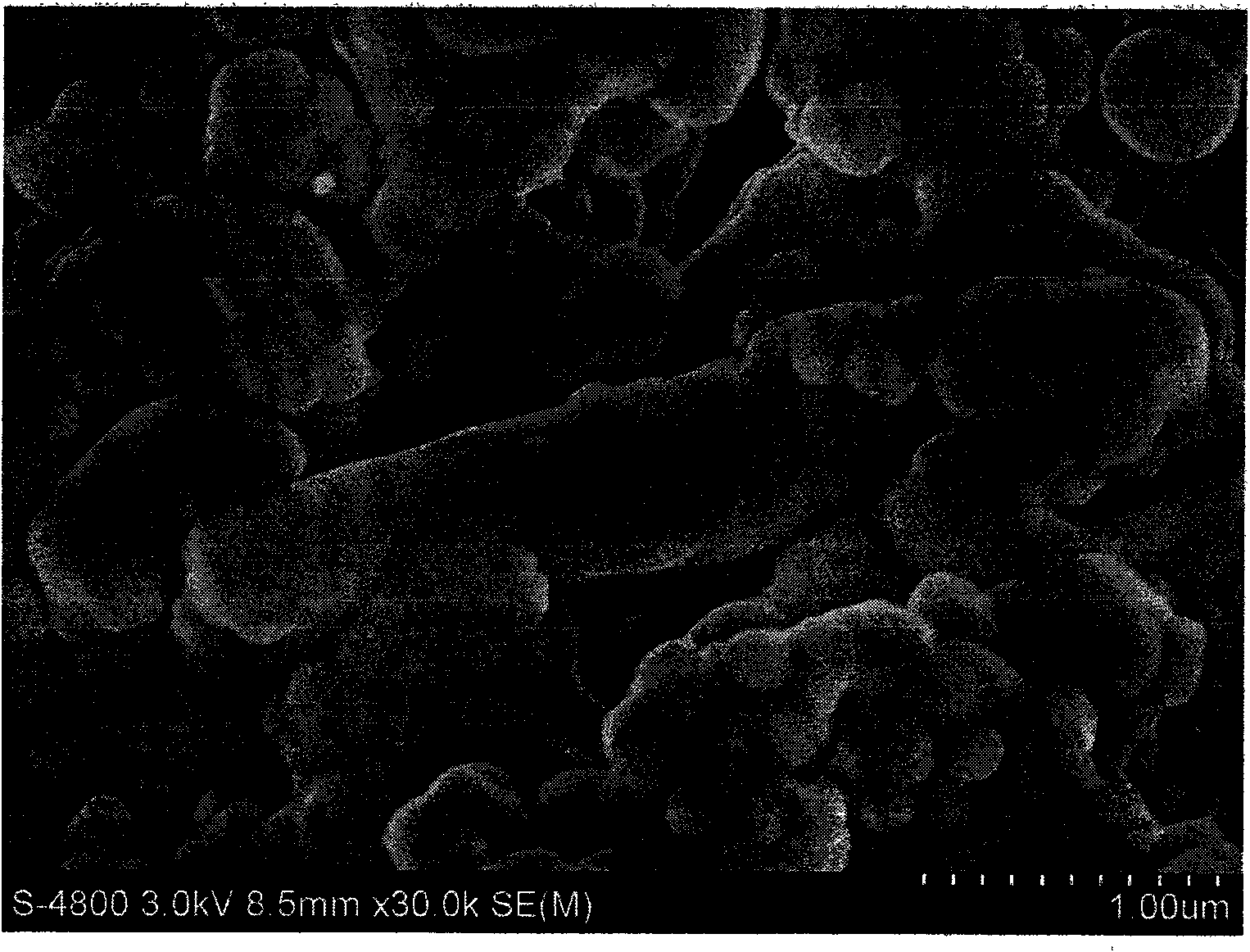

[0068] Low-temperature hydrothermal preparation of silicon nitride porous material with a porosity of 35.5% has the following steps:

[0069] The first step: preparation of ceramic molded body

[0070] First, uniformly mix α-silicon nitride powder with a median particle size of 0.5 μm, β-silicon nitride powder with a median particle size of 1 μm, and deionized water to prepare the first intermediate;

[0071] Adding ammonia water with a concentration of 2 mol / L to the first intermediate to adjust the pH of the first intermediate to 10, thereby preparing the second intermediate;

[0072] Add acrylic acid amine to the second intermediate and make the third intermediate after ball milling for 180 minutes; the ball milling speed is 300r / min;

[0073] Add silica sol to the third intermediate, stir and degas under vacuum, inject into the mold, put in the drying temperature of 80±5°C, dry for 50 minutes, and demould to obtain a ceramic molded body;

[0074] Dosage: Add 172g of α-si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com