Method of lowering sinter temperature of (Zr0.8 Sn0.2) TiO4 ceramic

A technology of zr0.8sn0.2 and sintering temperature, applied in the field of microwave dielectric material manufacturing, can solve the problems of complex glass composition, complex preparation process, and increased dielectric loss, and achieve low cost, simple preparation process, and low sintering temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Example

[0011]

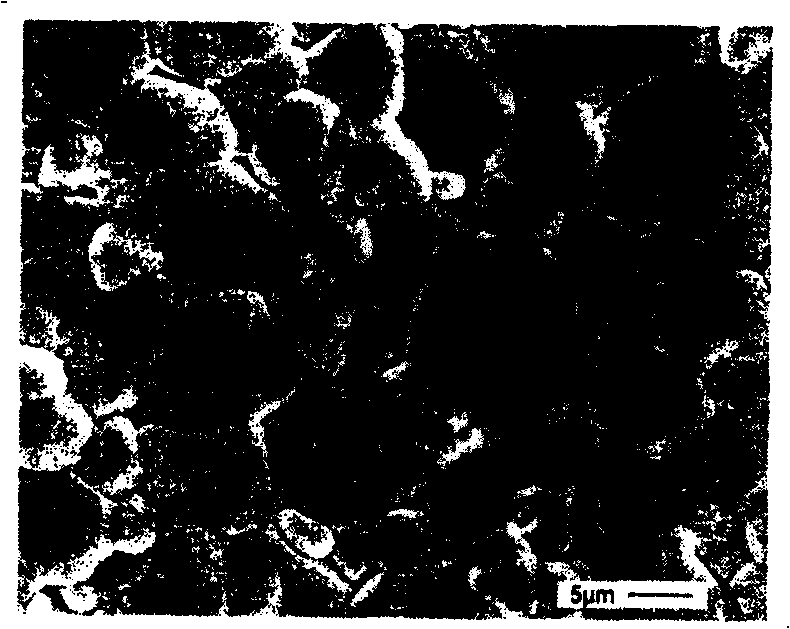

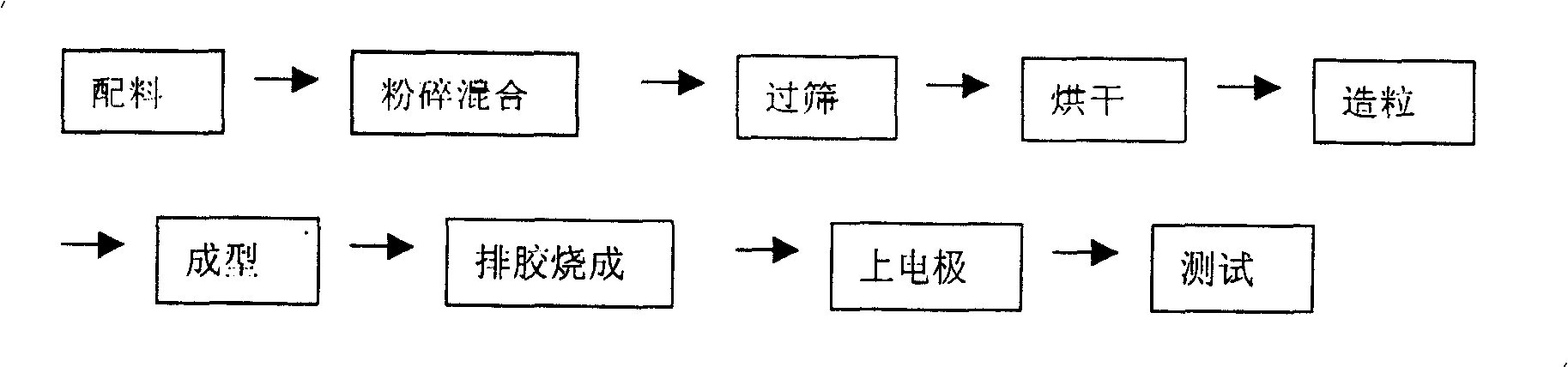

[0012] The present invention adopts conventional process to prepare ceramic material, and concrete process is as figure 2 , it can be seen that when the main material is doped with 4wt% lead boron glass and 3wt% Bi 2 o 3 / Li 2 O frit, when the sintering temperature is 1250°C, the dielectric properties of ceramics are the best, figure 1 It is to adopt the microstructure of the sintered material of the present invention at 1250°C, and the ceramic grains are uniform and dense. This is because the low-melting point additives first form a liquid phase to promote sintering during the sintering process, and are absorbed as the final phase at the later stage of sintering. The main crystal phase plays the role of doping modification. This "dual effect" of low-melting point additives allows lower sintering temperatures with constant or improved properties.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com