Thermal treatment preparation method of silicon negative electrode plate

A silicon anode, heat treatment temperature technology, applied in battery electrodes, electrical components, circuits, etc., can solve the problems of battery cycle performance decline, high energy density, foil oxidation, etc., to simplify the heat treatment process, easy to industrialize production, and improve cycle performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

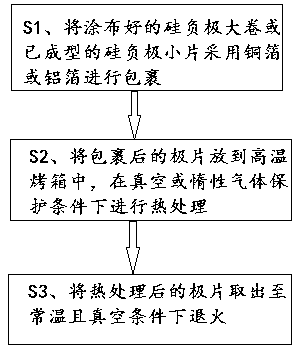

[0018] Please refer to figure 1 A heat treatment method for a silicon negative pole piece provided in this embodiment includes the following steps S1, wrapping the coated silicon negative pole roll or the formed silicon negative pole piece with copper foil or aluminum foil; S2, wrapping the Put the pole piece into a high-temperature oven, and perform heat treatment under the condition of vacuum or inert gas protection; S3, take out the heat-treated pole piece to normal temperature and anneal it under vacuum condition.

[0019] Specifically, the inert gas is nitrogen, and nitrogen has the advantages of being cheap and easy to obtain. Under the protection of vacuum or nitrogen, the coated silicon negative electrode roll or the formed silicon negative electrode chip is wrapped with copper foil or aluminum foil, which can Effectively prevent the oxidation of the silicon negative electrode. Of course, you can also use other airtight and high-temperature-resistant foil materials, or...

Embodiment 2

[0021] This embodiment is similar to Embodiment 1. As a further preferred solution, in this embodiment, the preferred heat treatment temperature in step S2 is 200-350°C, and the time is 0.5-2h, which not only saves time, but also improves the temperature of the pole piece material. Adhesive properties of the adhesive.

Embodiment 3

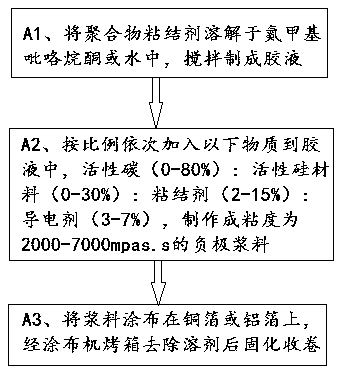

[0023] Please refer to figure 2 , the present embodiment provides the preparation method of the silicon negative pole coil, specifically as follows: A1, dissolving polyacrylic acid in nitrogen methyl pyrrolidone or water solvent, and stirring to make a glue; A2, adding the following substances to the glue in proportion Among them, activated carbon (0-80%): active silicon material (0-30%): binder (2-15%): conductive agent (3-7%), made with a viscosity of 2000-7000mpa.s Negative electrode slurry; A3. Coat the slurry on copper foil or aluminum foil, remove the solvent in the oven of the coating machine, and then solidify and roll.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com