Zinc alloys, sepiolite-ferric oxide and vermiculite-barium ferrate composite material and preparation method thereof

A technology of barium iron oxide and composite materials, which is applied in the field of metal materials, can solve problems such as poor absorbing performance, and achieve the effects of low production cost, convenient industrial production, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

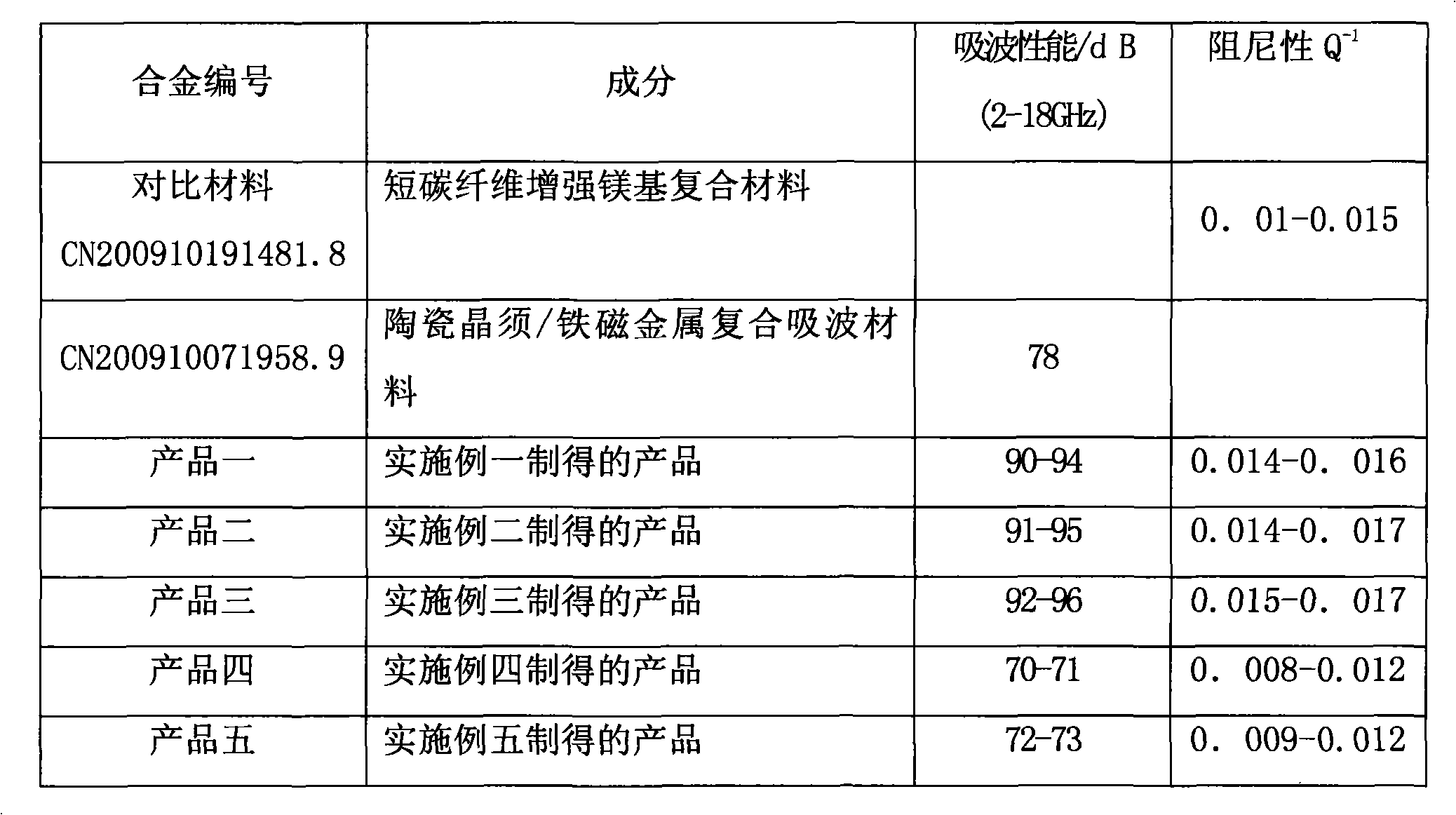

Examples

Embodiment 1

[0033] The preparation method of zinc alloy base sepiolite iron oxide vermiculite barium iron oxide composite material of the present invention, it comprises the following steps:

[0034] a. Preparation of Vermiculite Barium Iron Oxide Complex:

[0035] Add ferric chloride, barium nitrate and citric acid with water at a ratio of 1:5:5 to form a mixed solution of the three (add a small amount of water to dissolve), then put in vermiculite, stir in a water bath at 80°C for 10-20min, The size of the vermiculite particles is 0.1mm, and the weight ratio of the mixed solution of the three to the vermiculite is 5:1. After the stirring is completed, place the stirred material in an oven at 120°C for 30 minutes, cool it naturally, and then put it in a 550-590 In an oven at ℃, keep warm for 30 minutes and then cool naturally to obtain the vermiculite barium iron oxide compound.

[0036] b. Preparation of sepiolite iron oxide complex:

Embodiment 2

[0043] a. Preparation of the vermiculite barium iron oxide compound: the weight ratio of ferric chloride, barium nitrate and citric acid in the solution used for the preparation of the vermiculite barium iron oxide compound is 1:10:20, and the size of the vermiculite particles is 0.5mm , the weight ratio of solution and vermiculite is 10:1;

[0044] B. Preparation of the sepiolite iron oxide compound: the weight ratio of ferric chloride, ammonium ferrous sulfate and sepiolite in the solution used for preparing the sepiolite iron oxide compound is 1: 1: 2, the amount of sepiolite particles The size is 1mm;

[0045] c. Preparation of titanium fiber: V is 0.4% by weight, Pr is 0.003%, and the rest is Ti for batching.

[0046] d. Preparation of composite preform: the weight ratio of vermiculite iron oxide and sepiolite barium iron oxide composite is 1:2; the volume percentage of sepiolite iron oxide vermiculite barium iron oxide in the composite material is 40-50 %;

[0047] e....

Embodiment 3

[0050] a. Preparation of the vermiculite barium iron oxide compound: the weight ratio of ferric chloride, barium nitrate and citric acid in the solution used for the preparation of the vermiculite barium iron oxide compound is 1:7:10, and the size of the vermiculite particles is 0.3mm , the weight ratio of solution and vermiculite is 7: 1;

[0051] b. Preparation of the sepiolite iron oxide compound: the weight ratio of ferric chloride, ammonium ferrous sulfate and sepiolite in the solution used for preparing the sepiolite iron oxide compound is 1:1:1.5, the amount of sepiolite particles The size is 0.6-1mm;

[0052] c. Preparation of titanium fiber: containing V by weight percentage is 0.3%, Pr is 0.05%, and the rest is Ti for batching,

[0053] d. Preparation of composite prefabricated body: the weight ratio of vermiculite iron oxide and sepiolite barium iron oxide composite is 1:1.5; the volume percentage of sepiolite iron oxide vermiculite barium iron oxide in the composi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com