Preparation method of consumable electrode bar for copper-chromium electric arc melting

An arc smelting and consumable electrode technology, applied in the field of metal processing, can solve the problems of increasing arc smelting product defects, reducing product quality consistency, low density of prefabricated electrode rods, etc. The effect of reducing the gas content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A method for preparing a consumable electrode rod for copper-chromium arc smelting, comprising the following steps:

[0035] (1) Ingredients: by weight percentage, take 60% copper material and 40% chromium material for proportioning; copper material adopts electrolytic copper plate with a purity greater than 99.990%, and chromium material adopts chromium block with a purity greater than 99.9%, electrolytic copper plate and chromium The block is sanded to remove the surface oxide layer before smelting. The advantages of using electrolytic copper plate and chromium block are not easy to be oxidized and surface oxidized components are easy to remove compared with powdered raw materials.

[0036] (2) Ingot casting: the copper material and chromium material taken in proportion in step (1) are smelted and melted into liquid, and then poured into copper-chromium alloy ingot;

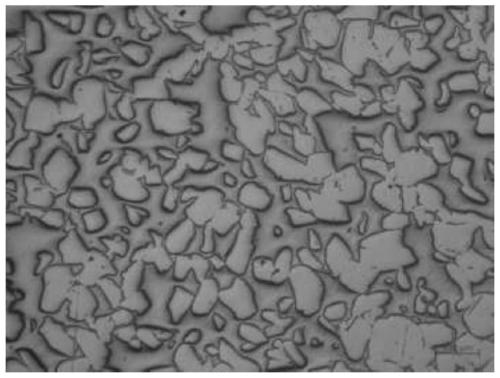

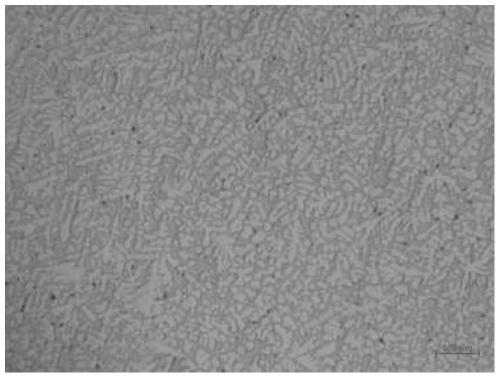

[0037] (3) Powder making: the copper-chromium alloy ingot is made into spherical copper-chromium all...

Embodiment 2

[0042] This embodiment is basically the same as that of Embodiment 1, except that, by weight percentage, 52% copper material and 48% chromium material are used for proportioning.

Embodiment 3

[0044] This embodiment is basically the same as that of Embodiment 1, the difference is that, by weight percentage, 90% copper material and 10% chromium material are used for proportioning.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com