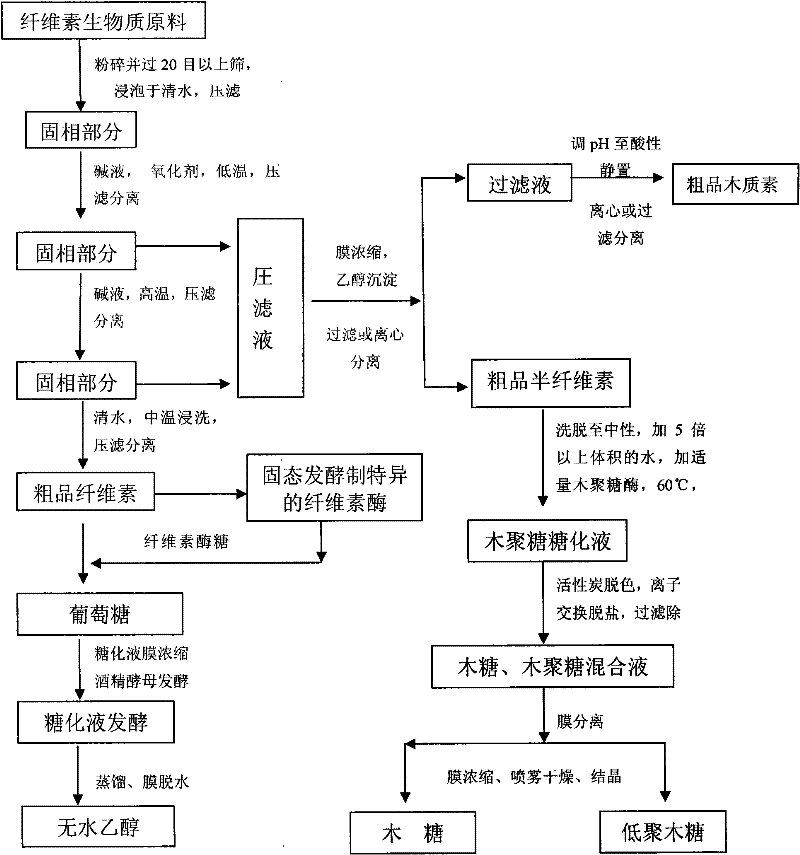

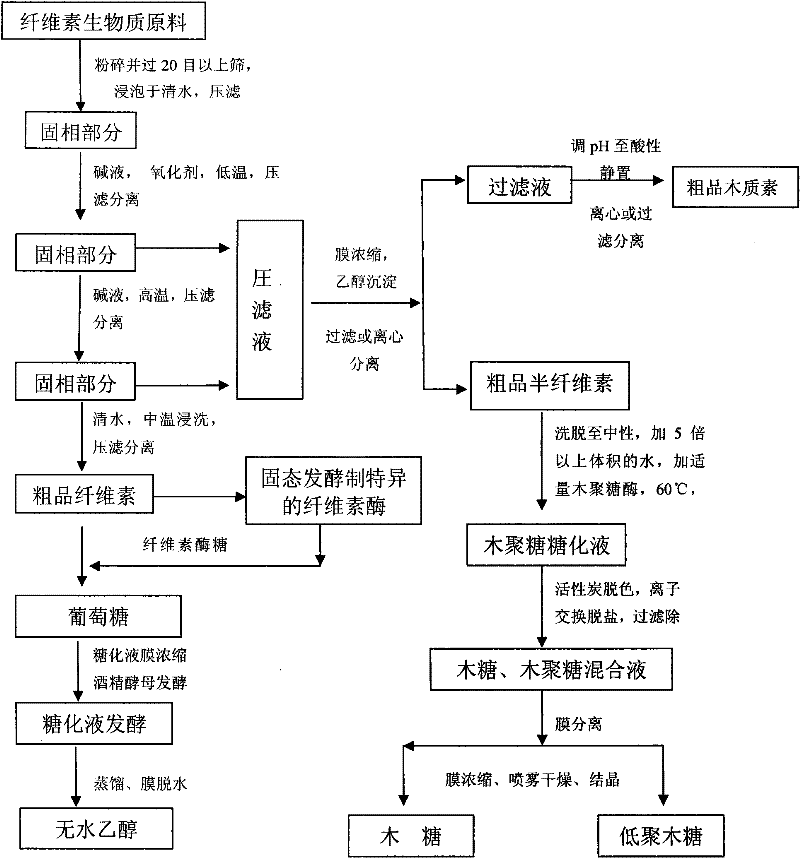

A method for fractional separation of full components of agricultural and forestry cellulose biomass and preparation of fuel alcohol and xylooligosaccharides by using the separated components

A separation method and fuel alcohol technology, which are applied in the directions of microorganism-based methods, biofuels, biochemical equipment and methods, etc., can solve the problems of low added value, high cost and low economic benefit, and achieve the improvement of heat utilization efficiency, The effect of reducing energy consumption and cost and improving economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A method for fractional separation of the full components of agricultural and forestry cellulose biomass used in this embodiment comprises the following steps:

[0025] 1. The fresh or dry matter of agricultural and forestry cellulose biomass is crushed, soaked in water first, and then press-filtered;

[0026] 2. Soak the solid phase part after 1 treatment with NaOH alkali solution with a concentration of 1%, the solid-liquid ratio is about 1:10 (WN), and add O with a concentration of 5%. 3 The oxidizing agent is firstly extracted at a medium temperature of 60°C for 2 hours, and the secondary liquid phase and the secondary solid phase are obtained after the secondary pressure filtration; the secondary solid phase is continuously soaked in 1% NaOH alkali solution, and the solid-liquid ratio It is about 1:10 (WN), extracted at a high temperature of 80°C for at least 1 hour, and obtained three solid phases and three liquid phases after three pressure filtrations; the three...

Embodiment 2

[0036] A method for fractional separation of the full components of agricultural and forestry cellulose biomass used in this embodiment comprises the following steps:

[0037] 1. After the dry matter of agricultural and forestry cellulose biomass is crushed, it is first soaked in clean water, and then press-filtered;

[0038] 2. Soak the solid phase after 1 treatment with 7% KOH alkali solution, the solid-liquid ratio is about 1:10 (WN), and add 5% H 2 o 2 The oxidizing agent is firstly extracted at a medium temperature of 60°C for 2 to 4 hours, and the secondary liquid phase and the secondary solid phase are obtained after the secondary pressure filtration; the secondary solid phase is continuously soaked in 7% KOH alkali solution, and the solid phase The liquid ratio is about 1:10 (WN), extracted at a high temperature of 140°C for at least 1 hour, and obtained three solid phases and three liquid phases after three pressure filtrations; the three solid phases are mainly crud...

Embodiment 3

[0048] A method for fractional separation of the full components of agricultural and forestry cellulose biomass used in this embodiment comprises the following steps:

[0049] 1. After the dry matter of agricultural and forestry cellulose biomass is crushed, it is first soaked in clean water, and then press-filtered;

[0050] 2. Treat the solid phase part after 1 treatment with 4% Na 2 CO 3 Soak in lye, the solid-liquid ratio is about 1:10 (W / V), add KMnO with a concentration of 4% 4 The oxidizing agent is first extracted at a medium temperature of 50°C for 3 hours, and the second liquid phase and the second solid phase are obtained after the second pressure filtration; the second solid phase part is continuously soaked in Na with a concentration of 4%. 2 CO 3 Among them, the solid-liquid ratio is about 1:10 (WN), extracted at a high temperature of 100°C for at least 1 hour, and the third solid phase and the third liquid phase are obtained after three times of pressure filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com