Waste heat recovering efficient gas stove

A waste heat recovery and gas stove technology, which is applied in the field of gas stoves, can solve the problems that the stove cannot be turned off (using an open flame or keeping a kindling, not supporting full combustion of gas, and large heat loss of fuel, etc., to improve the working environment and compact structure. , Improve the effect of heat utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing.

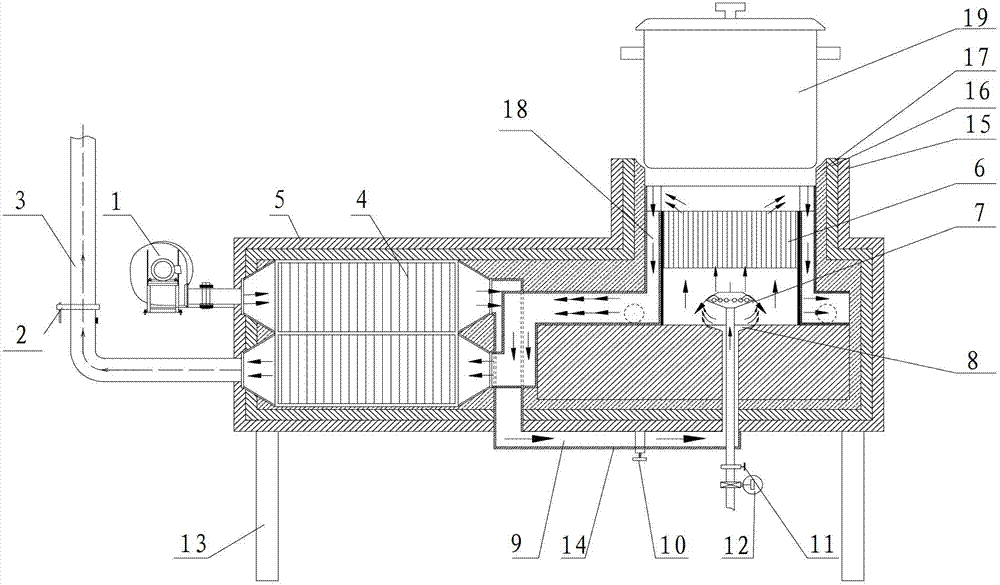

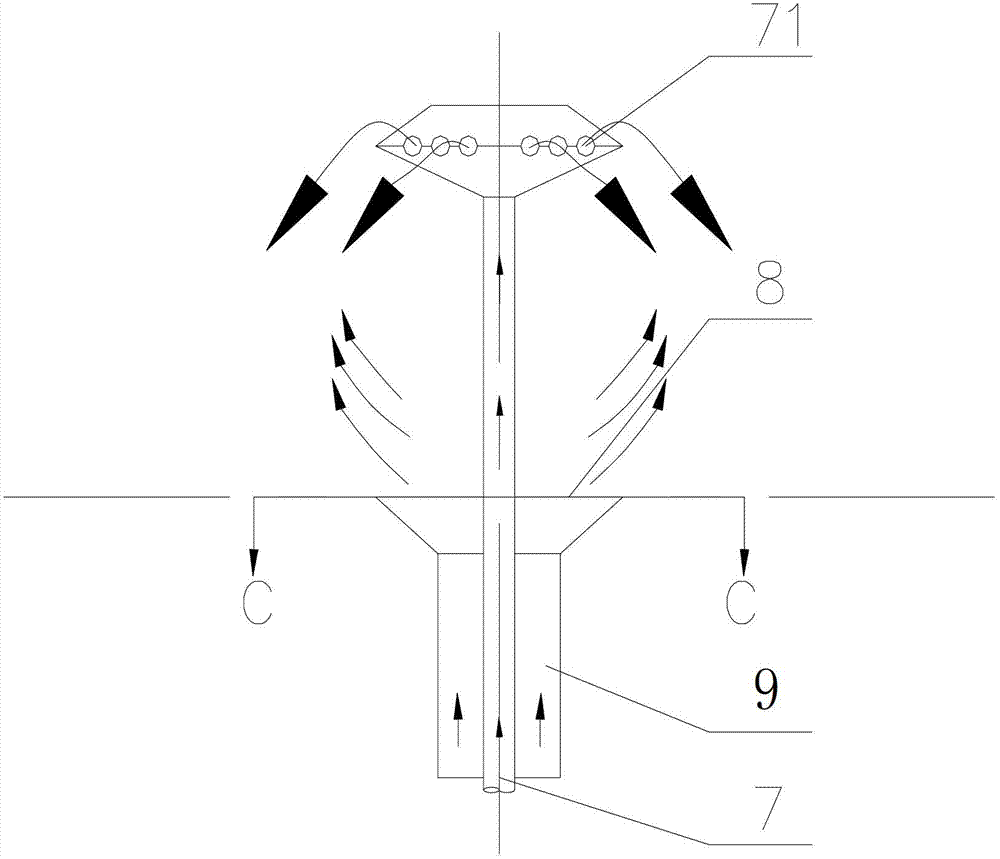

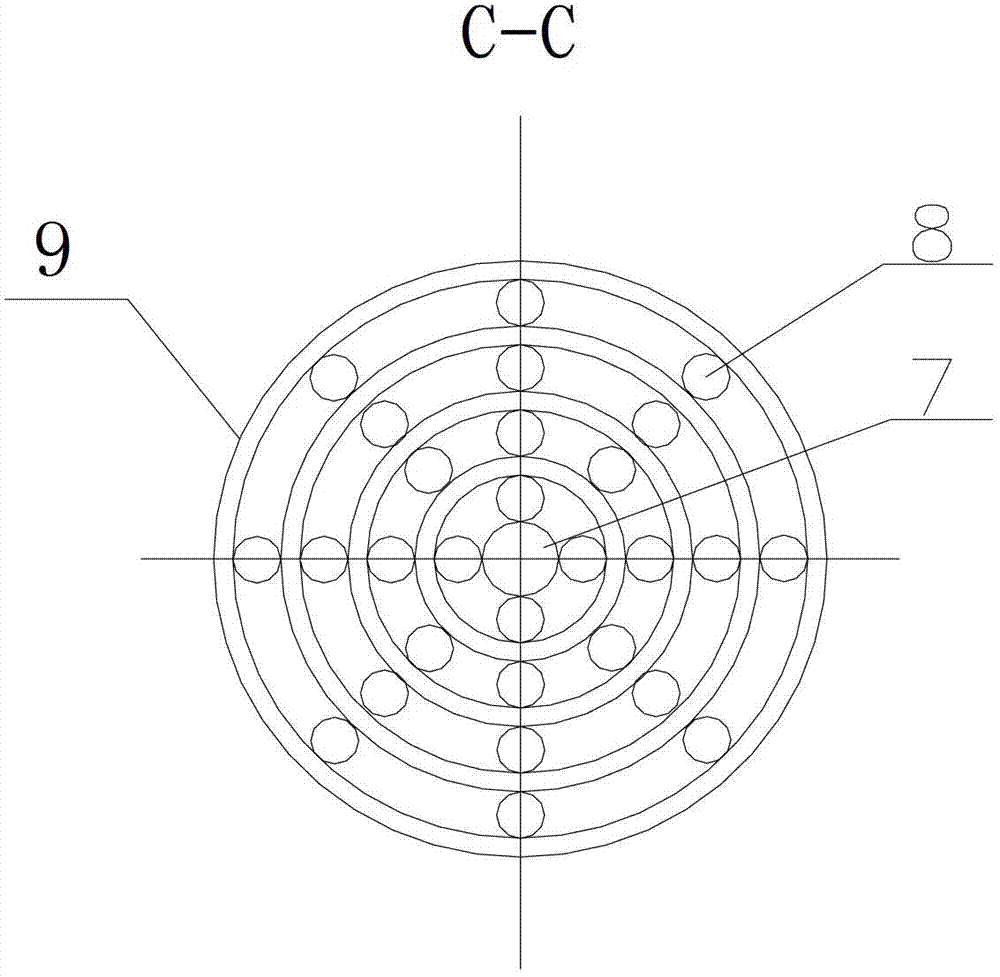

[0021] see figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 The bottom of the stove body 5 is provided with a bottom support steel column 13, and the stove body 5 is provided with a hearth, and the hearth is sequentially provided with a refractory layer 17, a heat insulation layer 16, and an insulation layer 15 from the inside to the outside, and a gas pipe 7 is arranged in the hearth. The stove body 5 is provided with a hot air pipe 9 that cooperates with the gas pipe 7 to supply air. The gas pipe 7 and the hot air pipe 9 are coaxially arranged. Air outlet 8, the gas outlet of gas pipe 7 is the radial gas outlet 71 that is located on the gas pipe 7, is provided with gas control valve 11 and flowmeter 12 on the gas pipe 7, is provided with cover in the hearth of stove body 5 The porous ceramic medium 6 of the gas pipe 7 and the hot air pipe 9 forms a combustio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com