ABS powder drying method

A drying method and powder technology, applied in the direction of drying solid materials, drying gas arrangement, heating to dry solid materials, etc., can solve the problems of unsatisfactory load, increased operating costs, and increased equipment investment, etc., to reduce powder The effect of reducing the loss, reducing equipment investment, and operating flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

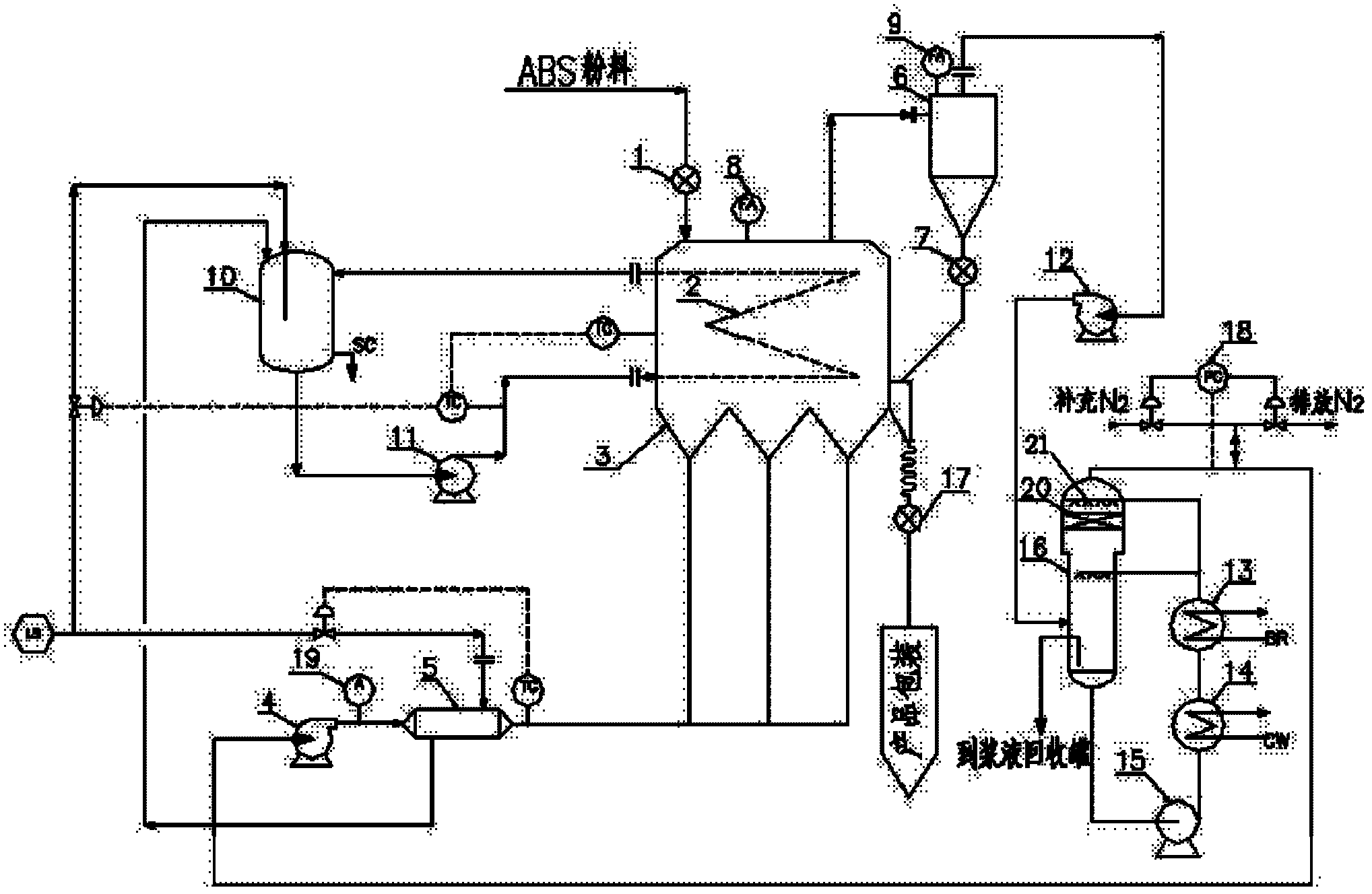

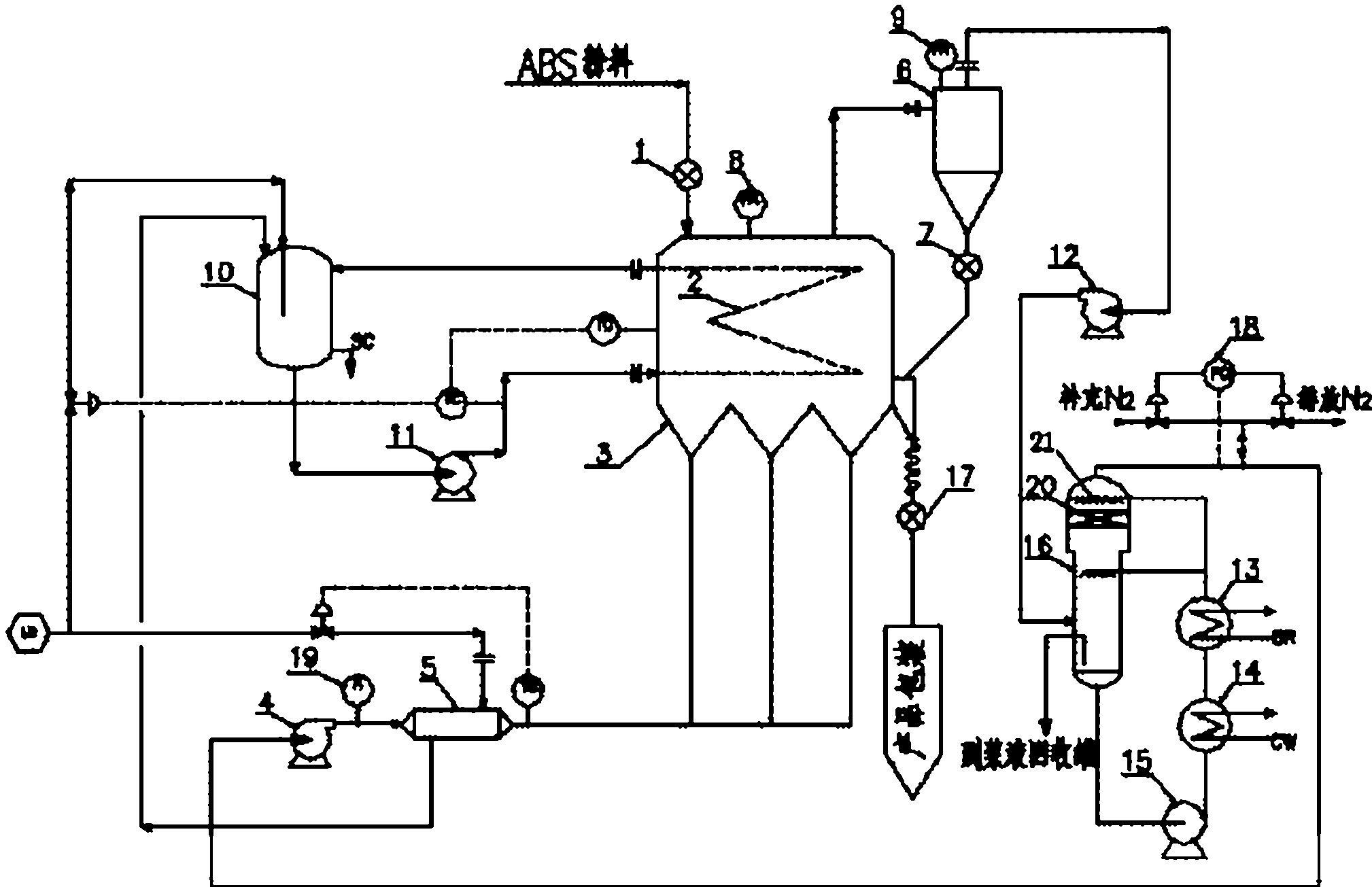

[0028] A drying method for ABS powder, comprising a powder drying step and a powder recovery step, wherein

[0029] In the powder drying step: the ABS powder is evenly added to the fluidized bed dryer 3 through the feeding valve 1, and the ABS powder is dried by the heater 2 in the fluidized bed dryer and the circulating hot air flow, and the fluidized bed The hot air discharged from the dryer is mixed with a certain concentration of fine powder. After passing through the cyclone separator 6, the separated powder passes through the first rotary valve 7, returns to the discharge port of the fluidized bed dryer 3, and passes through the second rotary valve. After 17, it is transported to the packaging by air flow to complete the drying of the powder.

[0030] The waste heat utilization process of condensed water is also set in the powder drying step: the process system includes a nitrogen heater 5, a heater 2 inside the fluidized bed dryer 3, a buffer hot water tank 10 and a fir...

Embodiment 2

[0042] A drying method for ABS powder, comprising a powder drying step and a powder recovery step, wherein

[0043] In the powder drying step: the ABS powder is evenly added to the fluidized bed dryer 3 through the feeding valve 1, and the ABS powder is dried by the heater 2 in the fluidized bed dryer and the circulating hot air flow, and the fluidized bed The hot air discharged from the dryer is mixed with a certain concentration of fine powder. After passing through the cyclone separator 6, the separated powder passes through the first rotary valve 7, returns to the discharge port of the fluidized bed dryer 3, and passes through the second rotary valve. After 17, it is transported to the packaging by air flow to complete the drying of the powder.

[0044] The waste heat utilization process of condensed water is also set in the powder drying step: the process system includes a nitrogen heater 5, a heater 2 inside the fluidized bed dryer 3, a buffer hot water tank 10 and a fir...

Embodiment 3

[0056] A drying method for ABS powder, comprising a powder drying step and a powder recovery step, wherein

[0057] In the powder drying step: the ABS powder is evenly added to the fluidized bed dryer 3 through the feeding valve 1, and the ABS powder is dried by the heater 2 in the fluidized bed dryer and the circulating hot air flow, and the fluidized bed The hot air discharged from the dryer is mixed with a certain concentration of fine powder. After passing through the cyclone separator 6, the separated powder passes through the first rotary valve 7, returns to the discharge port of the fluidized bed dryer 3, and passes through the second rotary valve. After 17, it is transported to the packaging by air flow to complete the drying of the powder.

[0058] The waste heat utilization process of condensed water is also set in the powder drying step: the process system includes a nitrogen heater 5, a heater 2 inside the fluidized bed dryer 3, a buffer hot water tank 10 and a fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com