Steam drive exploitation method for heavy oil reservoir

A production method and technology for heavy oil reservoirs, which are applied in the fields of production of fluids, earth-moving drilling, wellbore/well components, etc., can solve the problems of low utilization rate of steam heat energy, steam channeling, and no description of potential safety hazards, and achieve high thermal efficiency. Effectiveness of utilization efficiency and recovery factor, increasing fluidity and oil quality, and improving oil displacement seepage conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

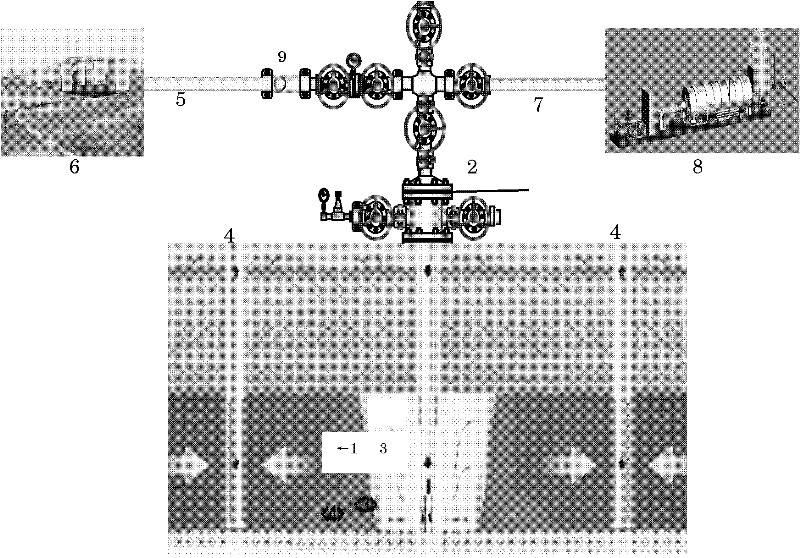

[0057] Such as figure 1 As shown, in the heavy oil layer 1, the steam flooding injection-production well pattern is deployed between the steam injection well 2 and the production well 4 in a reverse nine-point manner, and both the steam injection well and the production well are completed in a prestressed manner.

[0058] A long-term heat-insulated steam injection pipe string 3 is lowered into the steam injection well to reduce steam heat loss and improve the dryness at the bottom of the well. The long-term heat insulation steam injection pipe string 3 used is composed of E-grade heat insulation pipe, QK331-152 high temperature long-term steam drive packer, Y441-152 forced unsealing steam drive packer, JM-100 heat insulation pipe connection A long-term heat-insulated steam injection string composed of hoop sealer and heat-insulated telescopic pipe.

[0059] Among them, the E-class heat-insulated pipe is a vacuum heat-insulated pipe, which adopts a prestressed vacuum heat-insu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com