Waste salt treating device and process

A process and molten salt technology, applied in the field of devices for processing waste salt, can solve problems such as insufficient combustion efficiency and less than 30% thermal efficiency, and achieve the effect of improving thermal utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

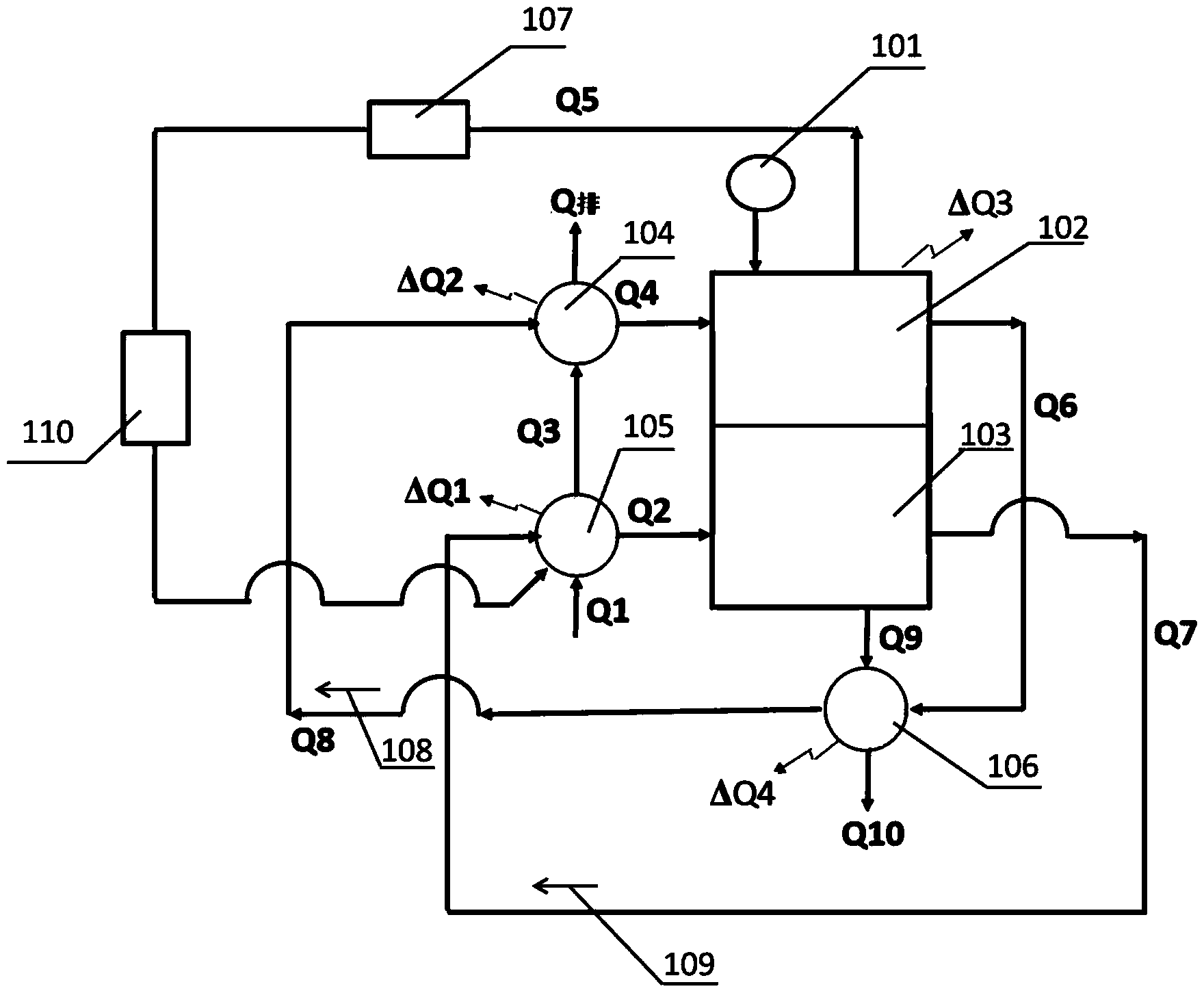

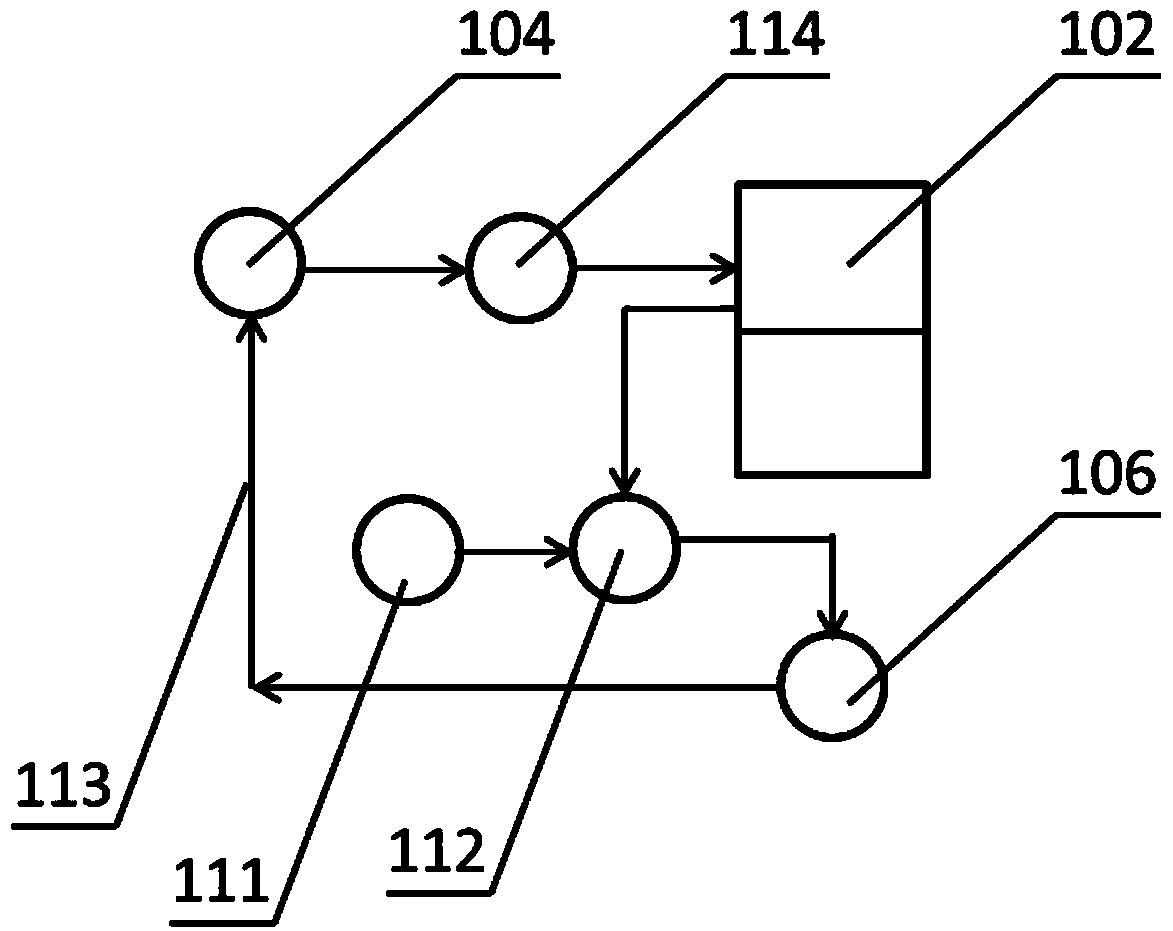

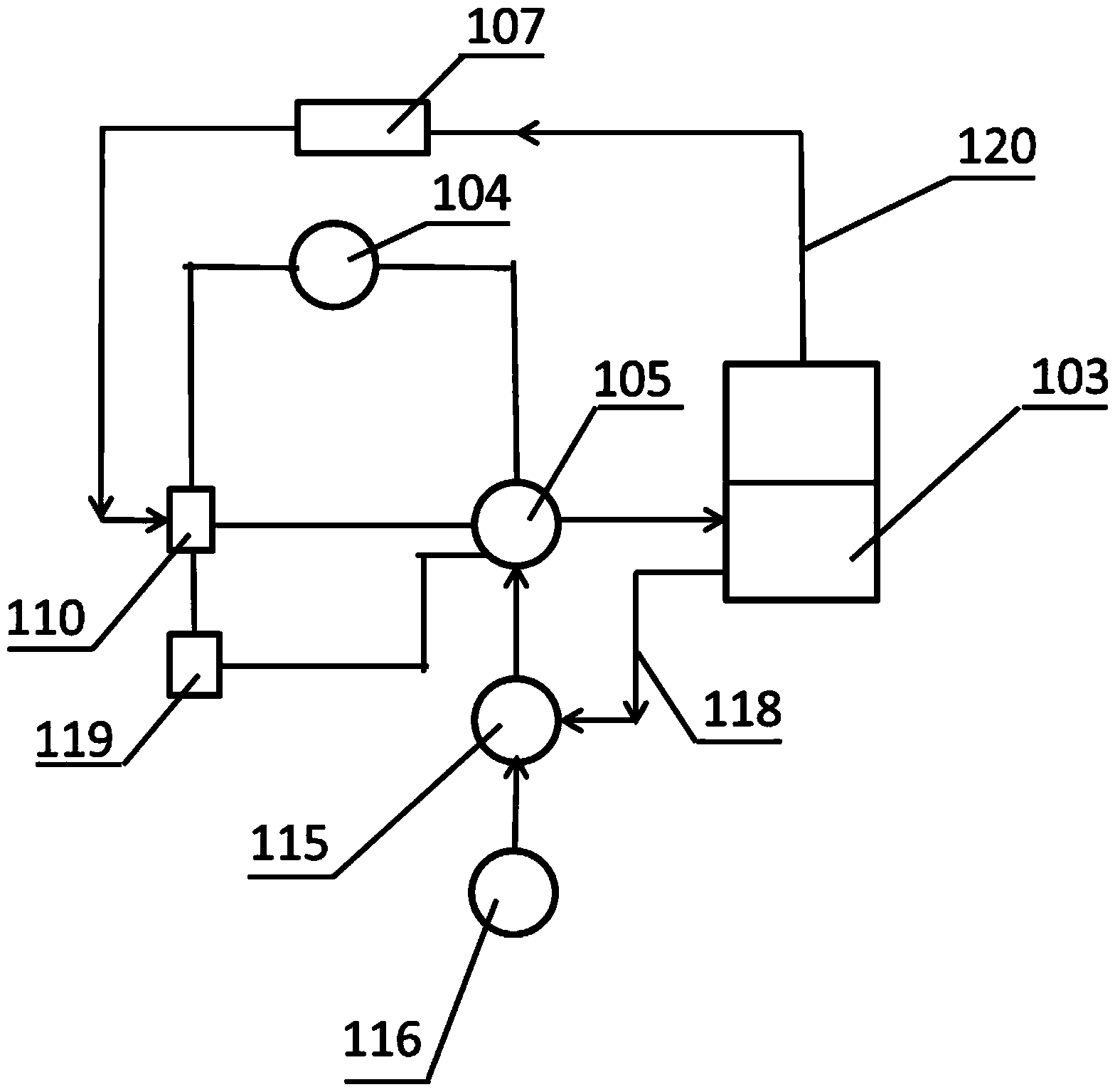

[0038] Such as Figure 1~3 As shown, a preferred embodiment of the present invention provides a device for treating waste salt, its structure includes an industrial feeder 101, a multi-stage indirect heating furnace, a heat transfer oil circulation system, a molten salt circulation system, organic waste gas transportation machine 107 and waste salt waste heat recovery device 106; the inlet of the multi-stage indirect heating furnace is connected with the industrial feeder 101, and its discharge port is connected with the waste salt waste heat recovery device 106; the multi-stage indirect heating furnace includes at least the first The first section of indirect heating furnace 102 and the second section of indirect heating furnace 103, the first section of indirect heating furnace 102 uses heat transfer oil as the heating source, the second section of indirect heating furnace 103 uses liquid molten salt as the heating heat source; the first section of indirect heating furnace 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com