Construction method for realizing fiber continuity at joints of concrete structure through molds

A technology of concrete structure and construction method, which is applied to the on-site preparation of building components, formwork/formwork/work frame, building construction, etc. It can solve the problems of fiber discontinuity, easy work and save construction cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

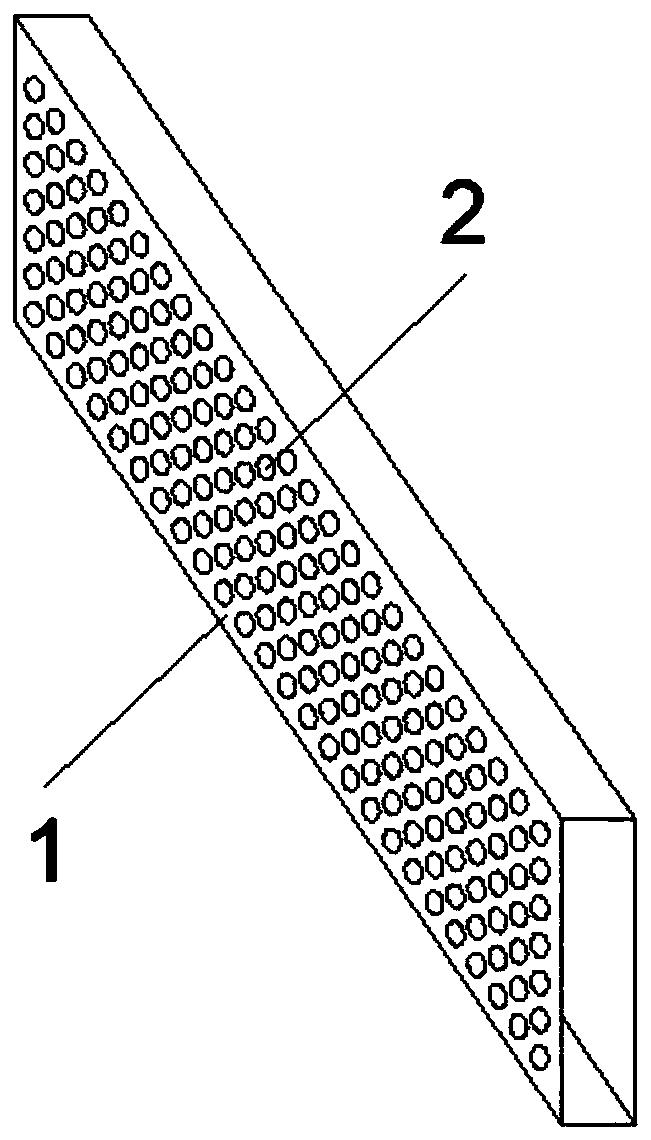

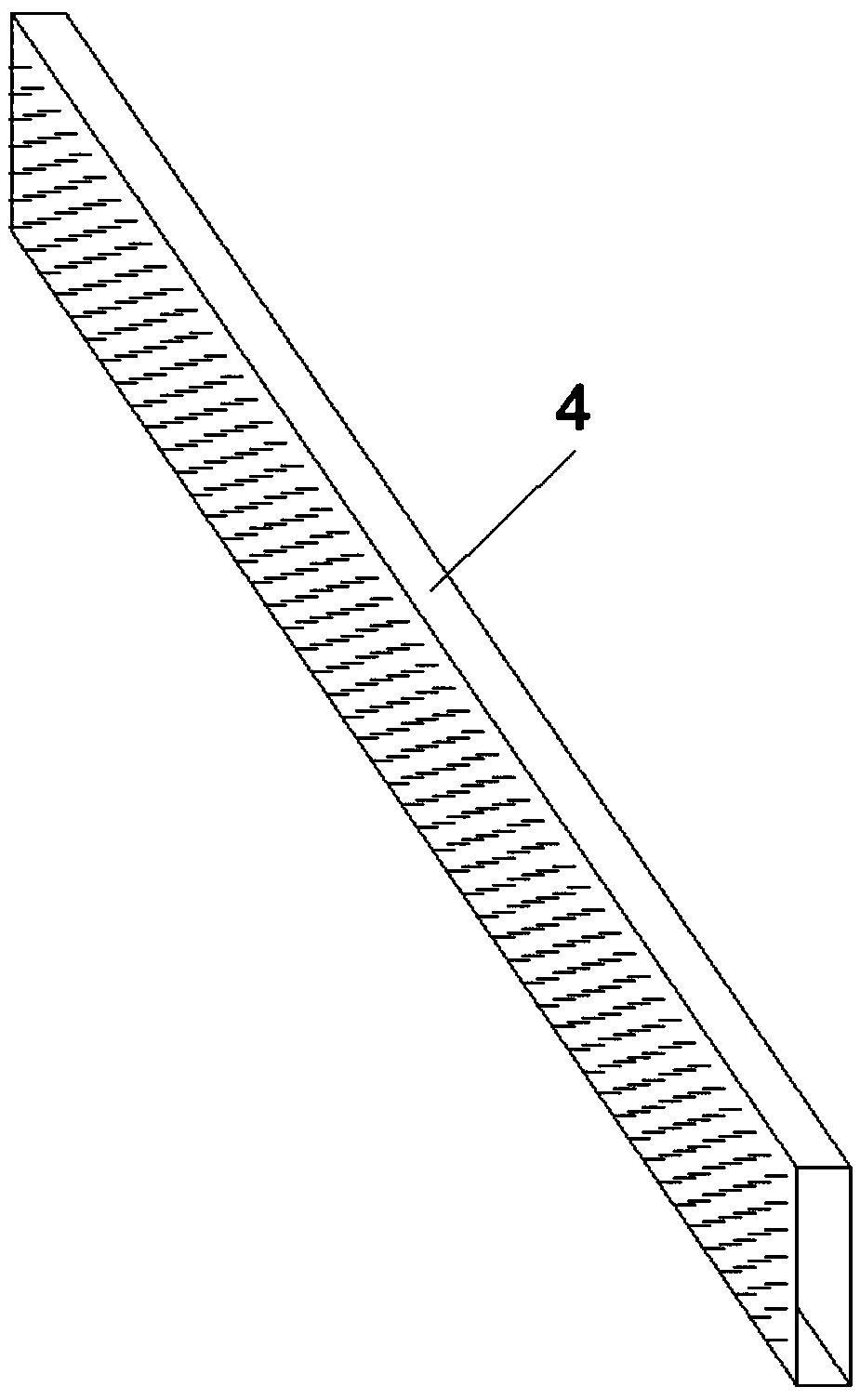

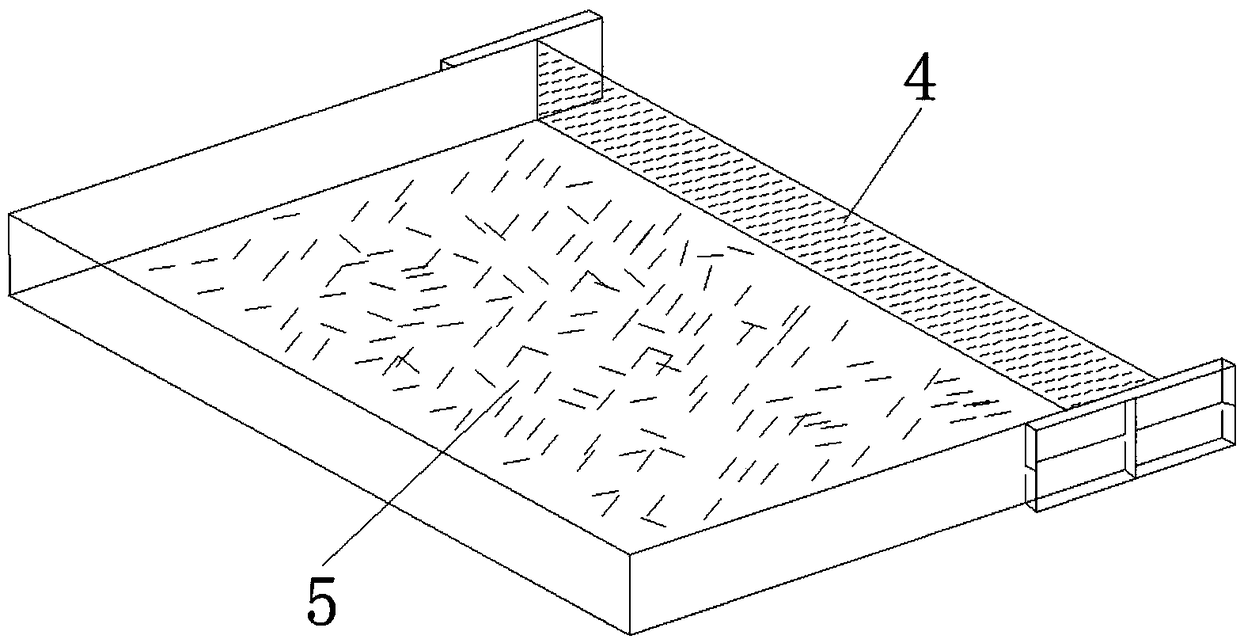

[0038] like Figures 1 to 6 As shown in one of the drawings, a construction method for realizing fiber continuity at the joint of a concrete structure by using a mold is roughly as follows: a plurality of fine holes 2 are drilled on one side of a rectangular plate-shaped mold 1, and then the fine holes 2 are drilled. Insert fiber into the fiber so that the length of the fiber part is exposed, and then take a connecting plate 4 to cooperate with the mold 1, so that the exposed fiber part of the mold is inserted into the connecting plate 4 to form a connecting plate 4 with fibers inserted, and then the mold 1 and the connecting plate are connected. 4 is separated, and then the connecting plate 4 is matched with the concrete pouring formwork 3 and the connecting plate 4 is fixedly installed at the preset concrete joint, so that the exposed end of the fiber outside the connecting plate 4 is located on the preset concrete side of the first pouring, Then after the first concrete pou...

Embodiment 2

[0050] This embodiment is roughly the same as that of Embodiment 1, except that the concrete to be poured is a precast concrete slab, and fibers are inserted on each side of the precast concrete in the manner described in Embodiment 1 above, and then transported to the site. After the installation is in place, a cast-in-place belt is cast in place between the joints of the prefabricated slabs to connect the prefabricated slabs into a whole, so that the steel fibers between the prefabricated concrete slabs are continuous.

[0051] By adopting the above technical scheme, the advantages of the present invention also include: convenient construction, the connection performance of the joint interface can be increased by changing the shape, content and slenderness ratio of fibers on the joints of different batches of concrete structures, avoiding the need to change The interface shape, setting of connectors or special-shaped steel plates are convenient to enhance the mechanical behav...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com