Movable copying positioning frame of steel structure complex joint

A steel structure, movable technology, applied in the field of positioning frame, can solve the problem of repeated disassembly and assembly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

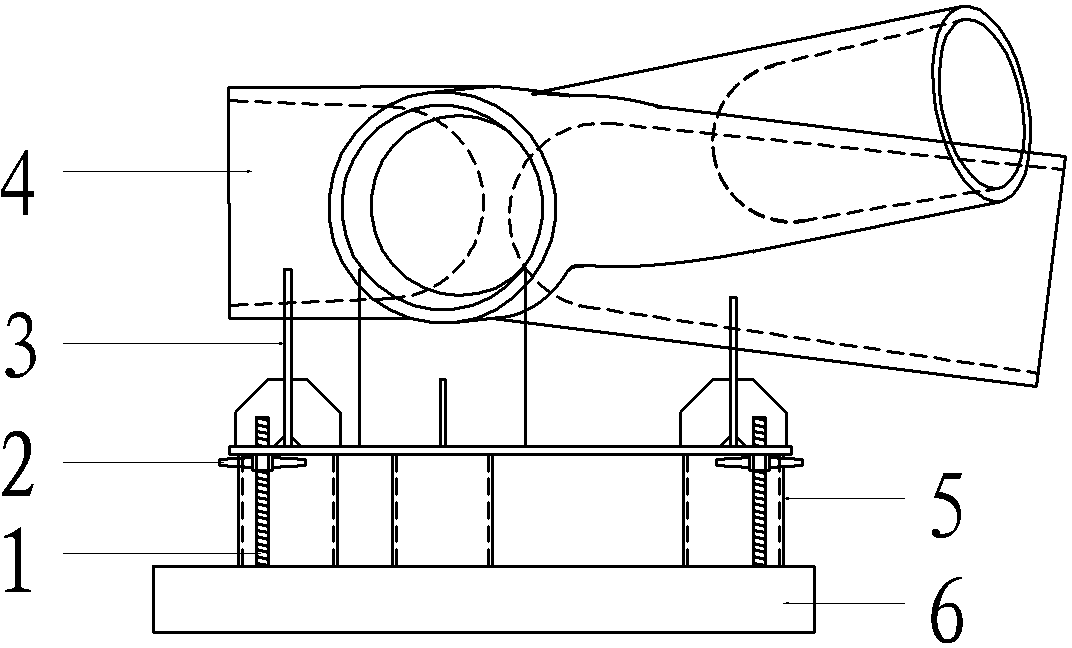

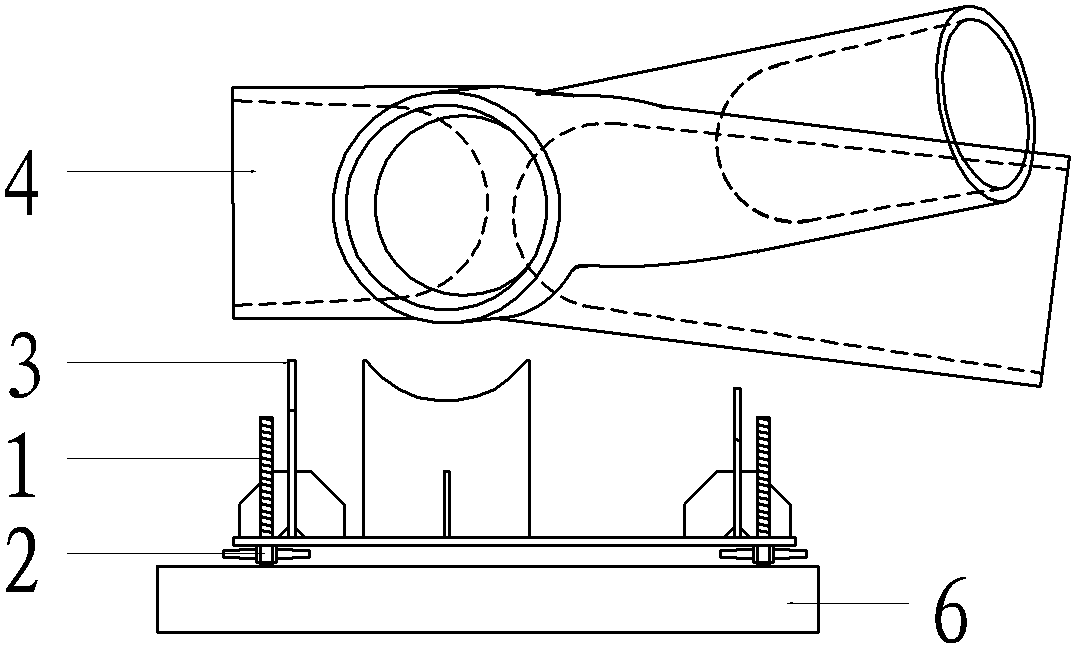

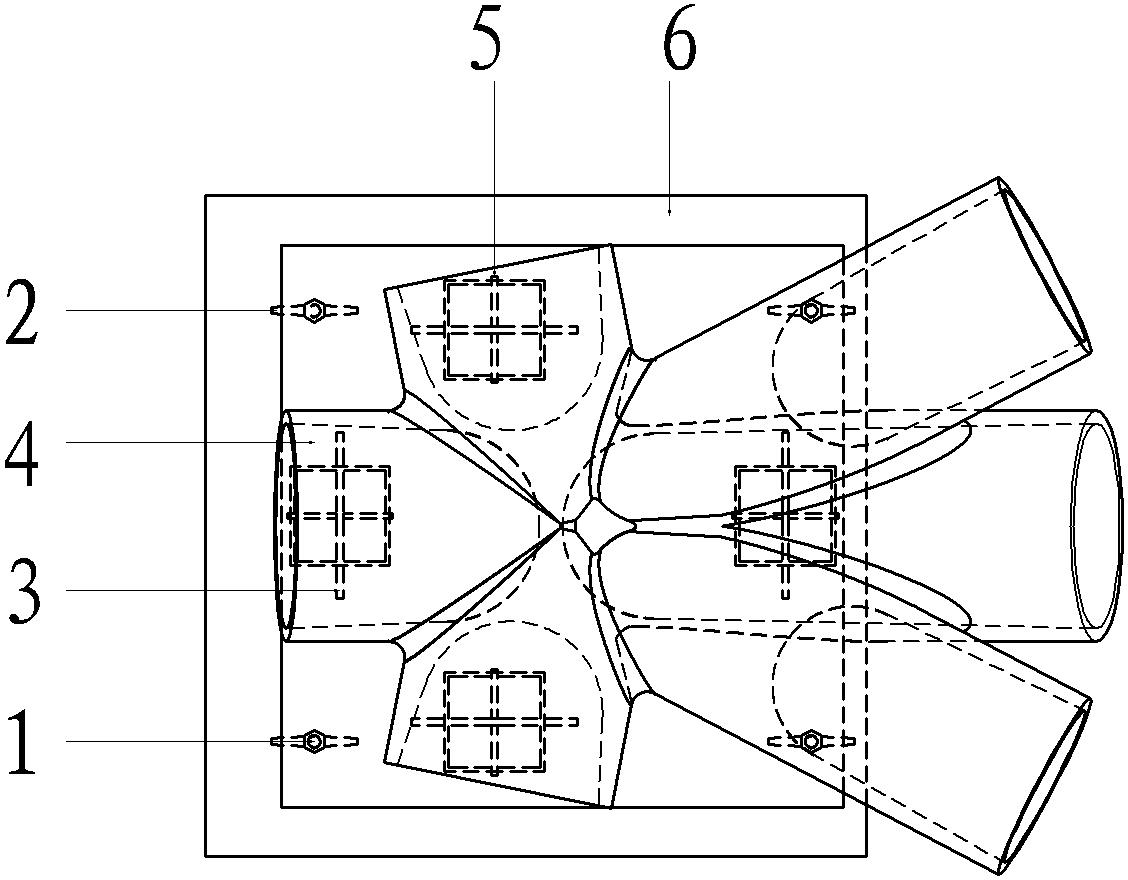

[0017] Such as Figure 1 to Figure 5 Shown: a movable profiling positioning frame for complicated steel structure nodes, which includes a profiling positioning frame 3, a screw rod 1 and an adjustment handle 2. The profiling positioning frame is composed of one base plate 32, four profiling positioning plates 33, and eight reinforcement plates 34. Four circular holes 31 are arranged on the base plate. Fitted and processed. Four screw rods 1 pass through the four round holes of the bottom plate of the profiling positioning frame to realize the plane positioning of the profiling positioning frame 3; the adjustment of the adjusting handle 2 can realize the positioning of the profiling positioning frame 3 in the vertical direction.

[0018] The usage method of this embodiment is as follows:

[0019] Such as figure 1 Shown: When installing for the first time, first weld the screw rod 1 to the steel platform 6 where the support frame is installed, adjust the adjustment handle 2 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com