Combined submarine cable untwisting system for untwisting submarine cables of various cross-sections

A combined, submarine cable technology, applied in thin material handling, conveying filamentous materials, transportation and packaging, etc., can solve the problem of inability to meet the requirements of high voltage level submarine cable retraction, the gravity of the submarine cable storage tray is large, and it is impossible to achieve To solve problems such as back-twisting, to facilitate lifting and supporting, increase cable storage capacity, and increase durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

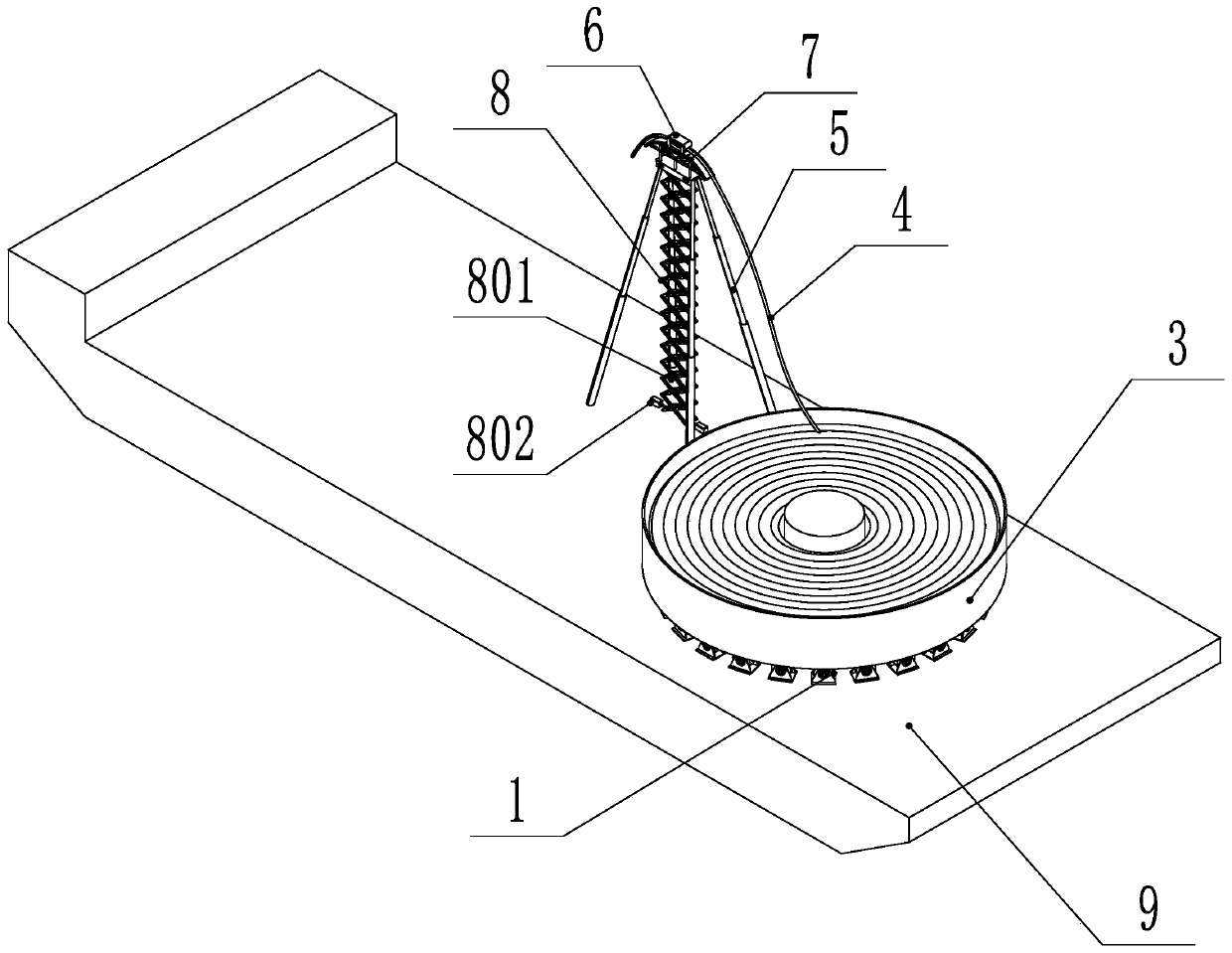

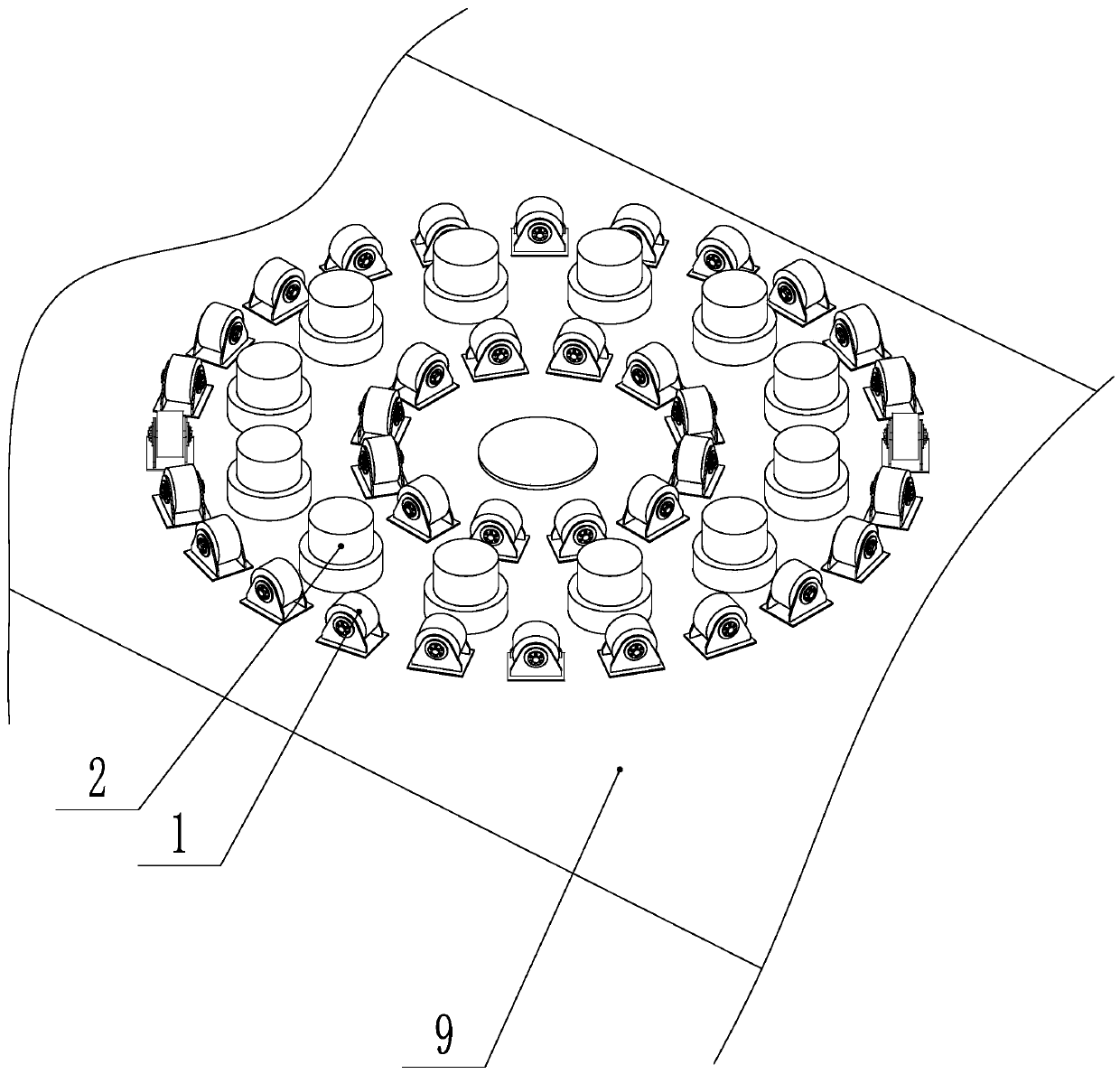

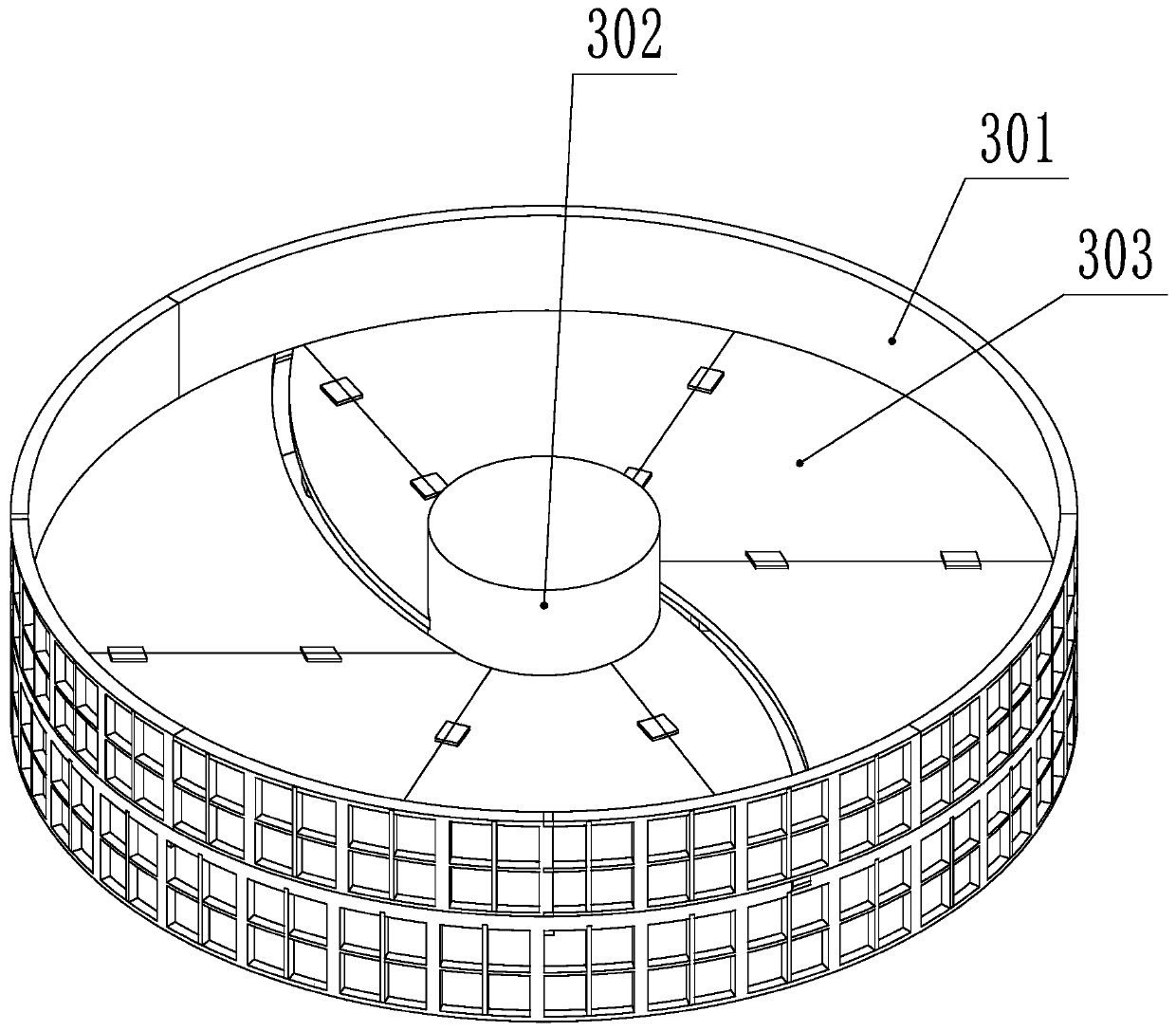

[0039] Such as Figure 1-5 As shown, the combined submarine cable untwisting system for various sections of submarine cable untwisting includes a submarine cable storage tray 3, 12 liftable load-bearing platforms 2, a liftable lifting tower 8, and is used to drive the tugboat 1 to rotate The submarine cable storage disk rotation drive device, the submarine cable bracket 7 arranged on the upper part of the lifting tower 8, the cable discharge tractor 6 for pulling the submarine cable 4, and the submarine cable storage disk rotation drive device and the cable discharge traction machine 6 are connected. The controller, the submarine cable storage disk rotation drive device, and the load-bearing platform 2 are set under the submarine cable storage disk 3; the 12 load-bearing platforms 2 and the submarine cable storage disk 3 are arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com