Involution positioning turnover system for assembling frame and wallboard of protective vehicle

A technology for positioning flipping and paneling, which is applied in transportation, packaging, motor vehicles, etc. It can solve the problems of lack of automatic positioning tooling, high labor intensity, and low production efficiency, and achieve the goal of reducing deformation, reducing workload, and improving work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

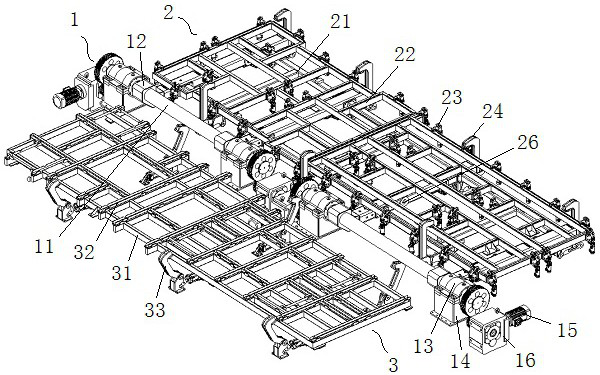

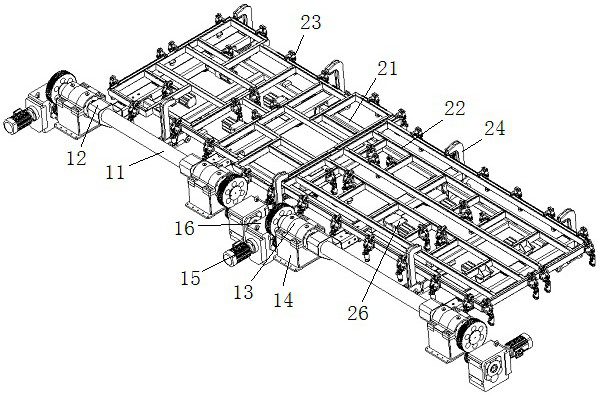

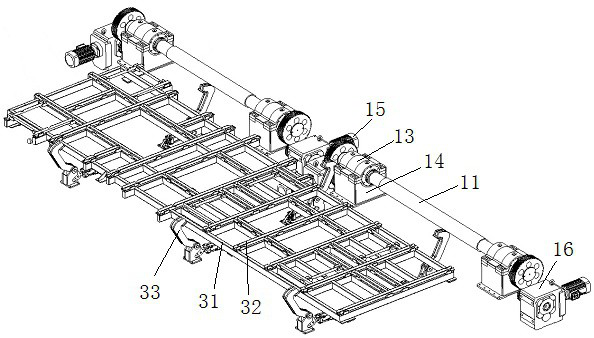

[0015] Such as Figure 1-5 As shown, the present invention is a pairing positioning turning system for the assembly of a protective vehicle frame and a wall panel, including a turning device 1, a panel clamping tool 2, and a frame clamping tool 3, and the wall panel clamping tool 2. The frame clamping tooling 3 is correspondingly arranged on both sides of the overturning device 1. The overturning device 1 includes a rotating shaft 11, the rotating shaft 11 is installed on the bearing seat 14 through the bearing 13, and the rotating shaft 11 is connected with the driving device. The driving device includes a motor 15 and a reducer 16, the motor 15 is connected with the rotating shaft 11 through the reducer 16, the wall clamping tool 2 includes a wall clamping frame body 21, and the wall plate clamping frame body 21 The connecting arm 12 is connected with the rotating shaft 11, and the wall plate clamping frame body 21 is equipped with a wall plate protruding plate 22 correspond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com