Convenient-to-use power cable corrector

A power cable and corrector technology, applied in the field of cable correction equipment, can solve problems such as repeated disassembly and assembly, and achieve the effects of improving the scope of application, reducing friction, and simple structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

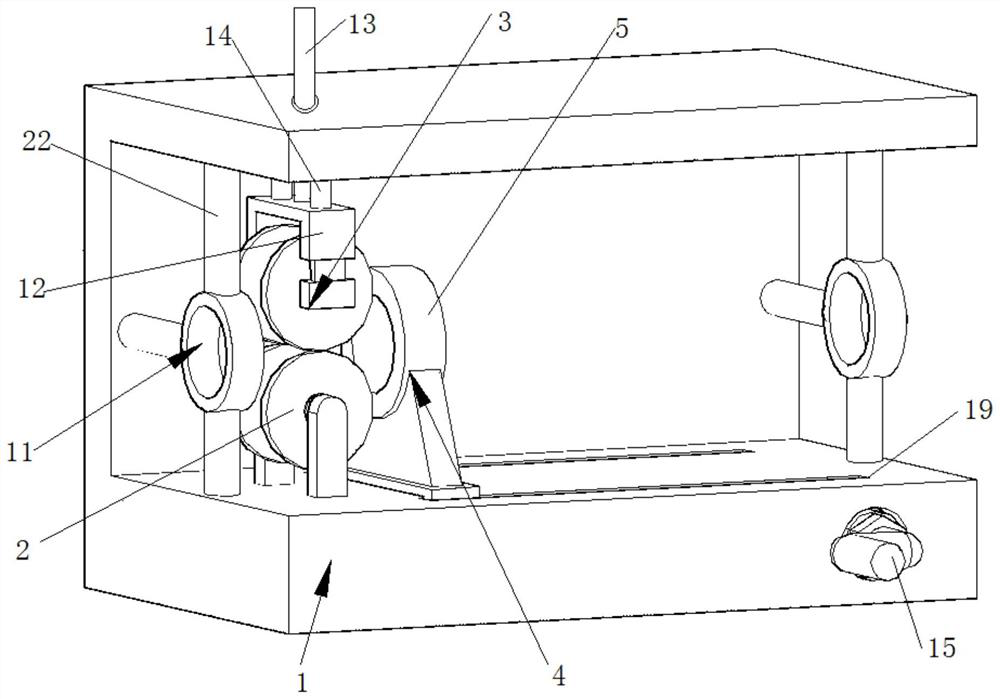

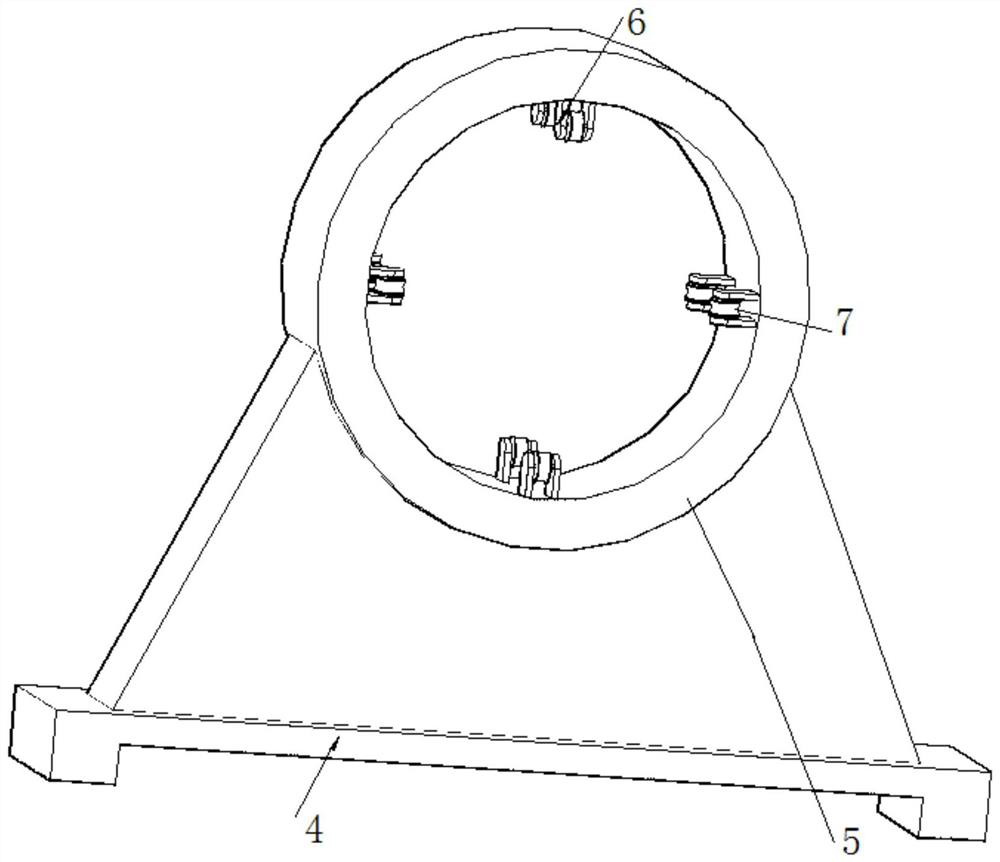

[0033] An easy-to-use power cable straightener such as figure 1 As shown, it includes a base 1 with a C-shaped cross section, a fixing mechanism, a flattening mechanism and a moving structure. The flattening mechanism includes a lower pulley 2 and an upper pulley 3. One side of the base 1 is provided with a lower pulley 2, and the other Side is provided with the upper pulley 3 of adjustable position, and upper pulley 3 is corresponding with lower pulley 2 positions.

[0034] Such as figure 1 and Figure 5 As shown, one side of the upper pulley 3 is provided with a connecting frame 12, and the connecting frame 12 is provided with an adjusting rod 13 threadedly connected with the base 1; Turn the adjustment rod 13 to change the height of the connecting frame 12, and then change the distance between the upper pulley 3 and the lower pulley 4, so that it is suitable for cables of different specifications; and the adjustment rod 13 is screwed to the base 1, and is in a locked stat...

Embodiment 2

[0044] On the basis of Example 1, such as Figure 7 As shown, the moving structure further includes a telescopic rod 20 and a connecting block 21 , the telescopic rod 20 is provided on the lower side of the sliding seat 4 , and the other side of the telescopic rod 20 is movably connected to the connecting block 21 located on the side of the conveyor belt 18 . The connecting block 21 is always connected with the telescopic rod 20 when the conveyor belt 18 moves, and the user can turn the handle in one direction to realize the reciprocating movement of the slide seat 4, so as to move the cable from the flattening mechanism to the other side, which is convenient to use.

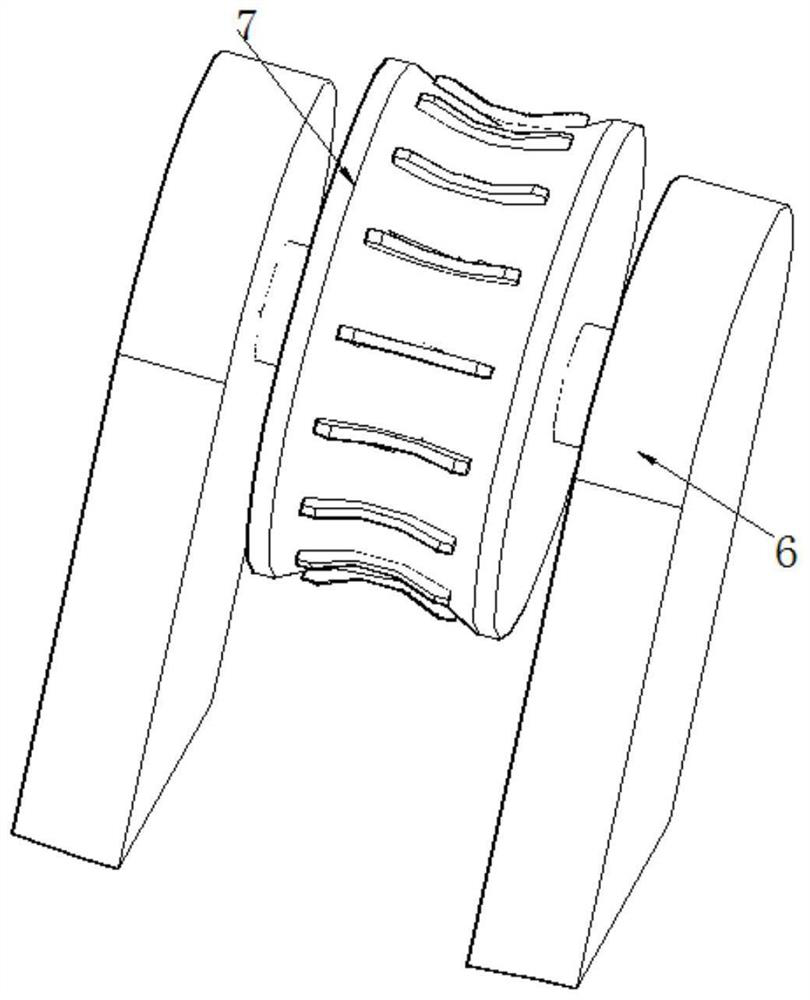

[0045] There are two sets of pawls 10 on the runner 7 , one set of pawls 10 is located in the wheel groove 8 , and the other set of pawls 10 is located between the outer side of the wheel groove 8 and the friction wheel 7 . One set of pawls cooperates with the wheel groove 8 to form a ratchet pawl structure, so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com