Method for positioning multiple brackets

A positioning method and technology of corbels, which are applied in construction, building structure, processing of building materials, etc., to achieve the effect of ensuring installation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Such as figure 1 Shown: a kind of multi-corbel positioning method, it comprises the following steps:

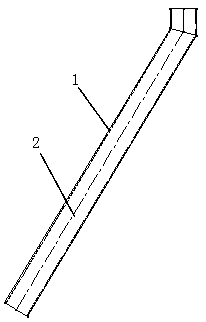

[0017] Step 1: Assembling the broken line column; the broken line column is welded by two columns 1, both of which are straight columns. Before welding, mark the center line 2 of the two columns on the surface of the column, and align the two columns when welding Weld the two columns into a broken line column, and the welding point of the two columns is the folding point;

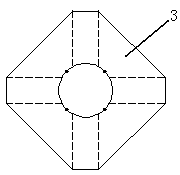

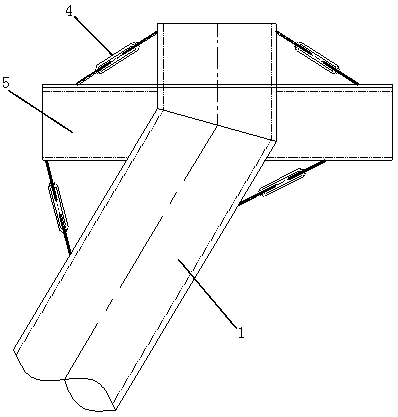

[0018] Such as Figure 2-3 Shown: Step 2: Horizontal corbel positioning; mark the distribution position of the horizontal corbel and the positioning point for determining the relative relationship between the corbel and the folding column on a horizontal steel plate 3 with a hole in the center, and insert the horizontal steel plate into the folding column At the top, align the positioning points on the steel plate and the folding column so that the horizontal steel plate is located on the top surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com