Method and apparatus for evaluating wear behavior of material

A behavioral, yet-to-be-evaluated technology, applied in the field of friction and wear of materials, which can solve problems such as difficulty in realistically evaluating wear behavior and wear mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] In this embodiment, the material to be evaluated is styrene-butadiene rubber for tires, its carbon black model is N220, and the opposite grinding material is a grinding wheel. The method for evaluating the wear behavior of styrene-butadiene rubber for tires is as follows:

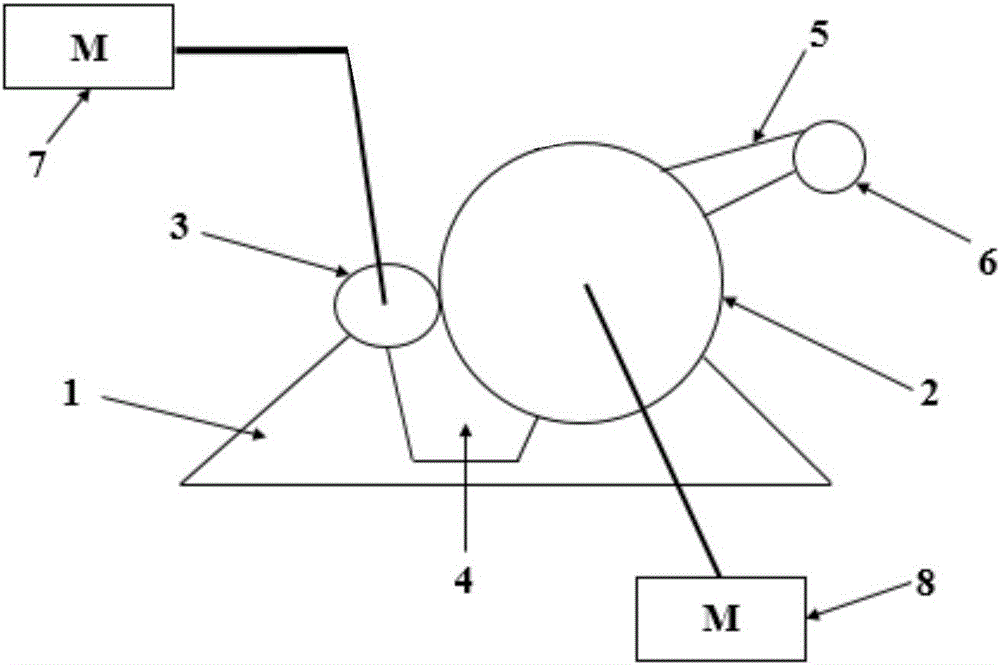

[0036] Such as figure 1 As shown, two independently rotatable rotating wheels are set on the base 1, one is the sample wheel 3 driven by the first motor 7, and the other is the counter grinding wheel 2 driven by the second motor 8. Styrene rubber is cut into long strips and adhered to the surface of the sample wheel. The styrene-butadiene rubber sample should not be subjected to tension during bonding, and the joint should be smoothly transitioned during bonding, and the sample wheel after bonding should be conditioned for at least 16 hours. The pair of grinding wheels is a commercial grinding wheel. The sample wheel is provided with a bracket 5 for loading, and a weight 6 is placed on the bracket ...

Embodiment 2

[0042] The carbon black model of styrene-butadiene rubber for tires to be evaluated in Example 1 was replaced with N330, and other conditions and evaluation methods were exactly the same as in Example 1.

Embodiment 3

[0044] The carbon black model of styrene-butadiene rubber for tires to be evaluated in Example 1 was replaced with N550, and other conditions and evaluation methods were exactly the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com