Back-up roll with adjustable and controllable interference

A technology of supporting rolls and interference, which is applied to rolls, keeping roll equipment in an effective state, metal rolling, etc., can solve the problems of core roll and roll sleeve interference fit stress relaxation, etc., to improve service life and reduce manufacturing costs. cost effect

Inactive Publication Date: 2012-07-04

YANSHAN UNIV +1

View PDF5 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The problem to be solved by the present invention is to provide a support roll with adjustable interference, so as to overcome the defect of stress relaxation in the interference fit between the core roll and the roll sleeve in the prior art

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

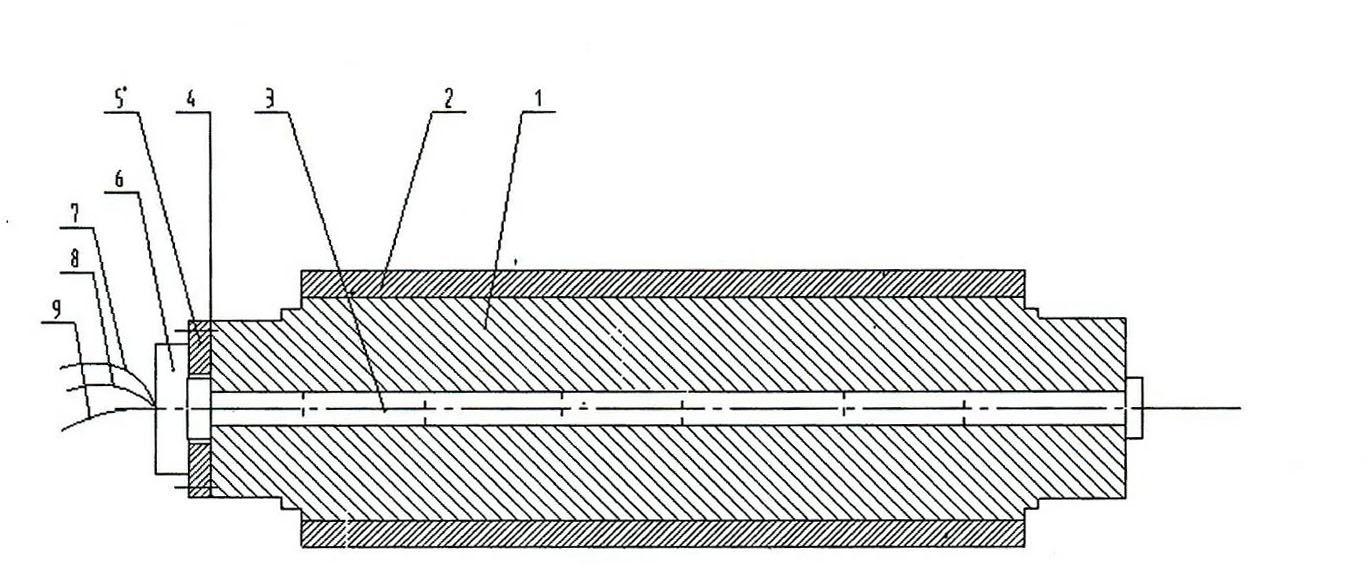

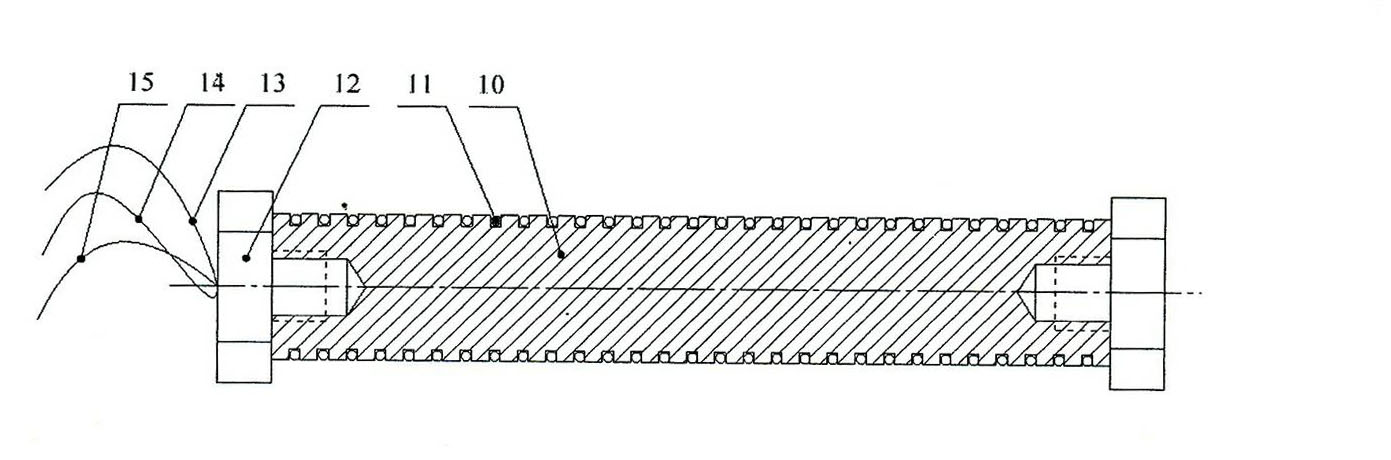

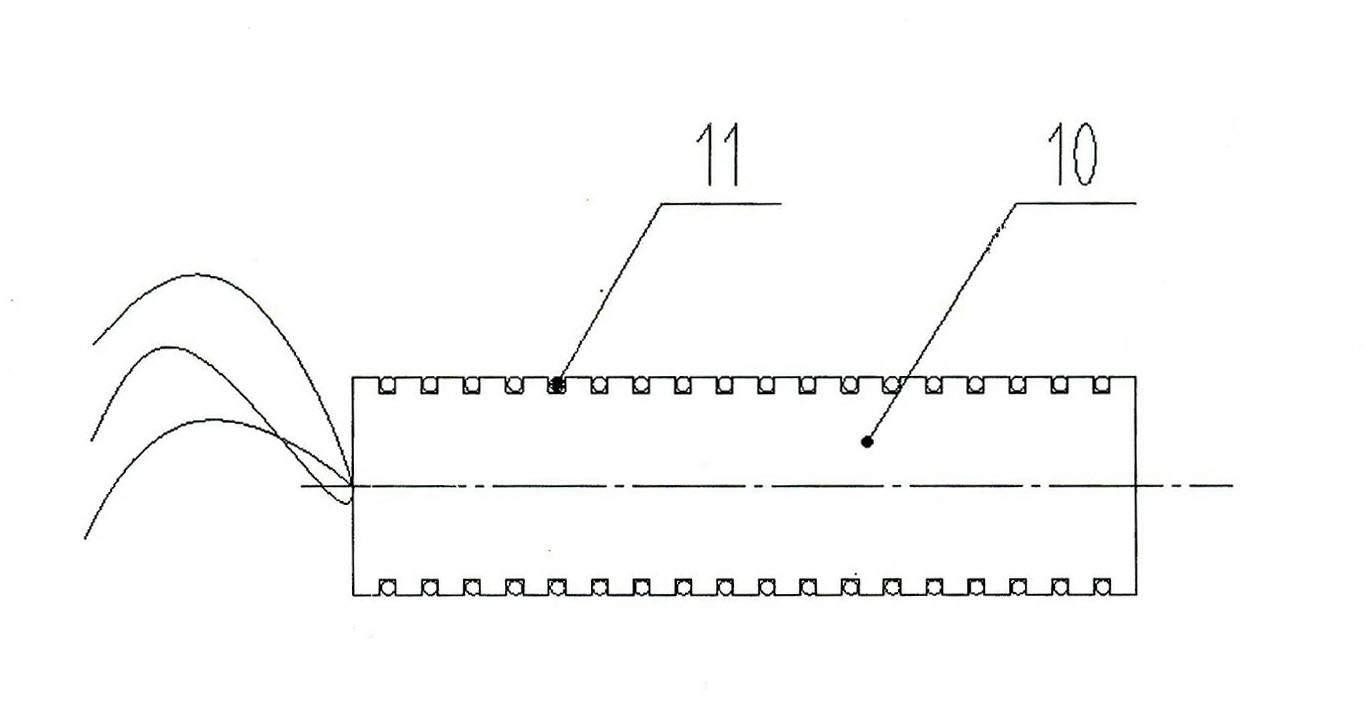

The invention discloses a back-up roll with an adjustable and controlled interference, which comprises a core roll and a roll sleeve arranged outside the core roll. The core roll is provided with a through hole; one or a plurality of groups of electric heating assemblies are arranged in the through hole; the end part of the core roll is provided with a connecting flange and a slip ring for power supply and signal output; when the interference fit stress between the roll sleeve and the core roll is insufficient to meet the rolling requirement, even the roll sleeve and the core roll slide relatively, the core roll is subjected to power-up heating, a roll core generates radial expansion by the electric heating assemblies and the pre-tightening force between the roll sleeve and the core roll is increased; and a roll shape curve of a sleeved roll is regulated by powering up a plurality of groups of electric heating assemblies. The back-up roll disclosed by the invention adopts a sleeving structure. The roll sleeve can be made of a high-strength wear-resistance alloy material and the core roll can ba made of a forged steel (or cast steel) material with low price, so that the manufacturing cost can be greatly reduced. When the roll sleeve is seriously worn, the roll sleeve can be directly replaced and the core coll can be repeatedly used. When the combined back-up roll is used for regulating and controlling the plate crown or the plate shape, the roll shape can be sectionally regulated in an expansion control mode. According to the invention, by expansion of the core roll, the interference fit quantity value of the core roll and the roll sleeve is always maintained, so that the service life of the combined back-up roll can be greatly prolonged.

Description

technical field [0001] The invention relates to the technical field of steel rolling equipment in the metallurgical industry, in particular to a support roll with adjustable interference and roll shape. Background technique [0002] In the industrial production of plates and strips, the back-up rolls of large-scale cold and hot continuous rolling mills, and the back-up rolls of large-scale wide and thick plate mills play an important role in the production of steel rolling industry. It can reach 5000mm, and its strength, rigidity and heat treatment process are designed to ensure that the rolling mill can produce qualified products. As an important consumable in the steel industry, rolls directly affect product quality and production costs. In the large-scale roll forming manufacturing process, forged steel backup rolls are mostly supplied to users in the form of integral processing. In order to improve surface strength, hardness and wear resistance, medium frequency induc...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B21B27/03B21B27/06B21B28/00

Inventor 杜凤山于辉臧新良黄华贵许志强杨霄玉杜凤林

Owner YANSHAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com