Elevator tow-drive rolling-sliding contact fatigue wear testing machine

A technology for elevator traction and contact fatigue, which is applied in the direction of testing wear resistance, using mechanical devices, measuring devices, etc., can solve the problem of inability to simulate the friction and wear of the elevator traction sheave rope groove and the friction pair of the wire rope groove surface, and can not be applied, etc. to avoid contact vibration and reduce contact vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

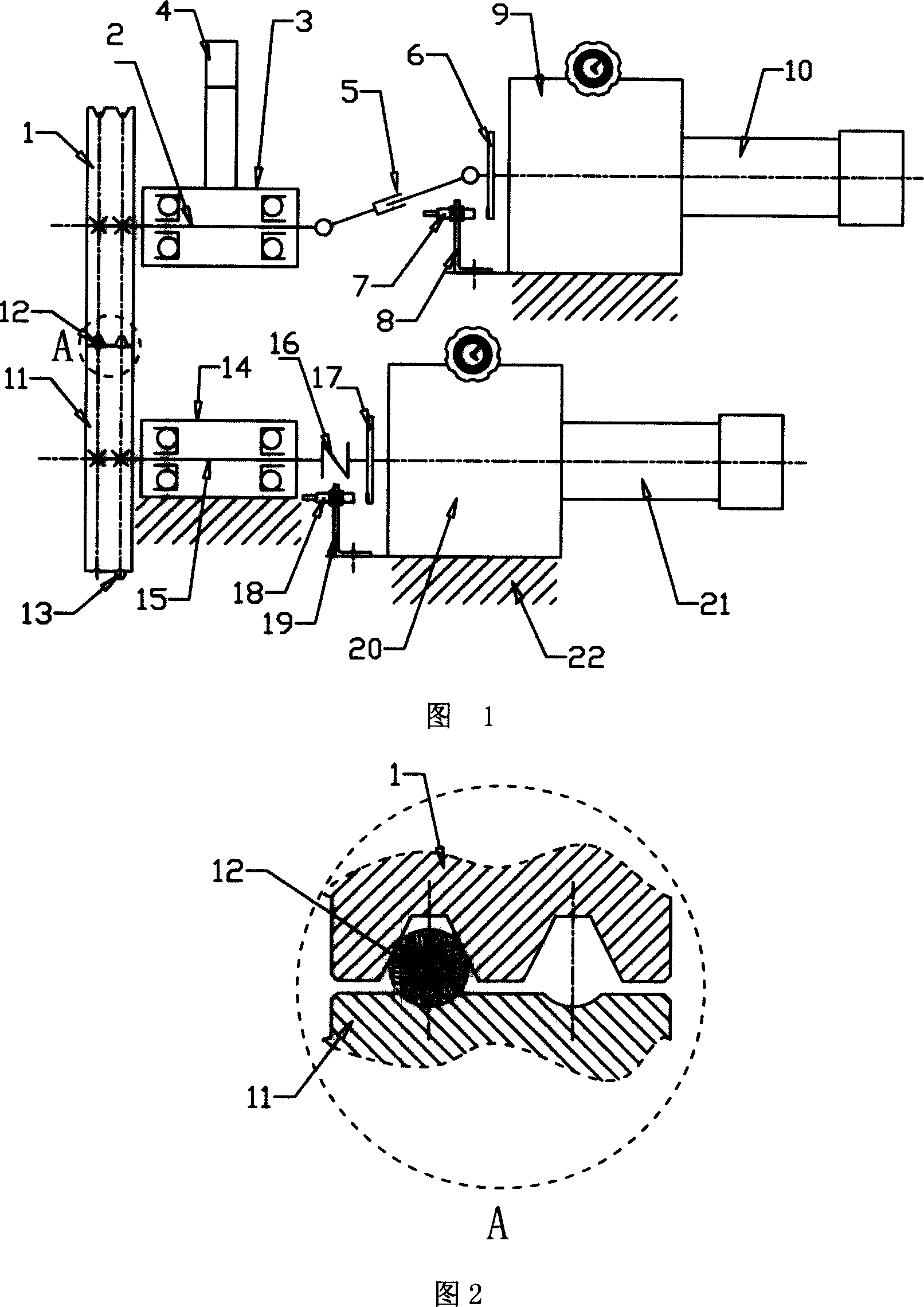

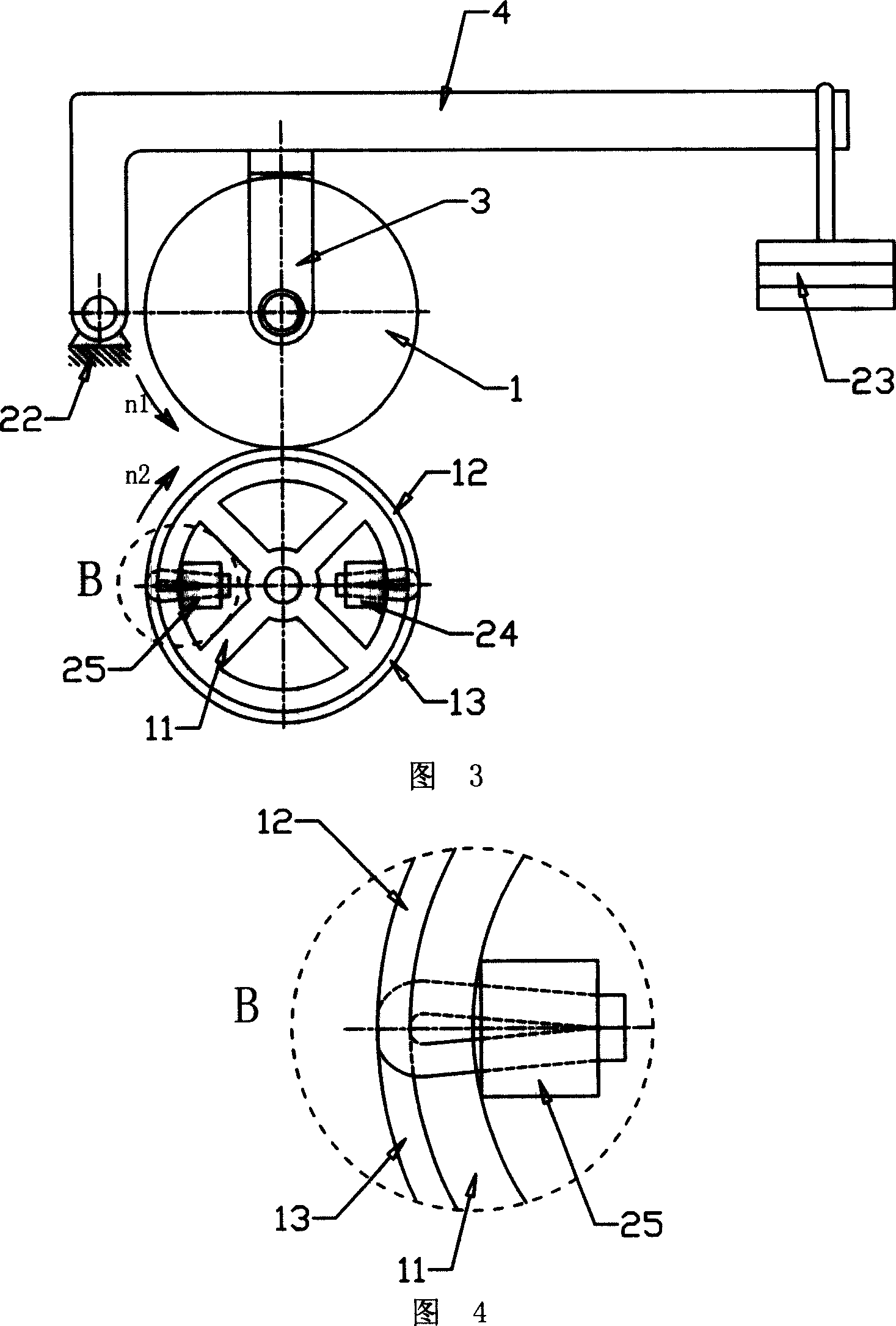

[0011] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: this embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following the described embodiment.

[0012] As shown in Figures 1-4, this embodiment includes: a traction wheel 1, an upper shaft 2, an upper bearing seat 3, a loading lever 4, a telescopic universal joint 5, an upper speed measuring disc 6, an upper sensor 7, Upper bracket 8, upper continuously variable transmission 9, upper motor 10, lower turntable 11, upper half wire rope 12, lower half wire rope 13, lower bearing seat 14, lower rotating shaft 15, coupling 16, lower speed measuring disc 17, lower sensor 18 , lower bracket 19, lower continuously variable transmission 20, lower motor 21, support 22, we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com