Anti-vibration parameter recording type spline milling cutter

A technology of parameter recording and spline, which is applied in the direction of milling cutters, milling machine equipment, milling machine equipment details, etc., can solve the problems of increased cutting and expansion, affecting the service life of machining precision tools, and being unable to effectively observe and record the working status of milling cutters. Achieve the effect of reducing contact vibration and conductive vibration and ensuring machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

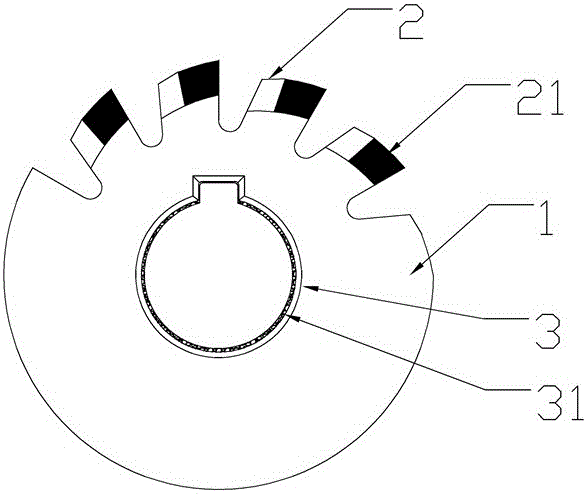

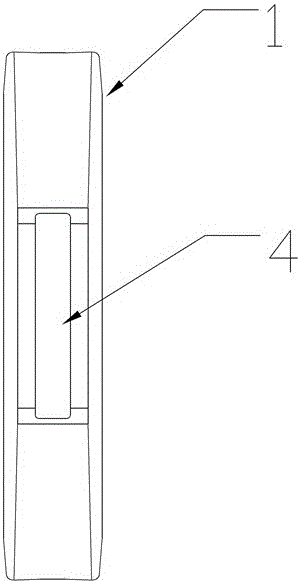

[0014] refer to figure 1 , 2 , an anti-vibration type parameter recording type spline milling cutter of the present invention, comprising a blade body 1, a blade 2, a fastening hole 3 and a monitoring recorder 4, the blades 2 are distributed on the upper edge of the blade body 1, arranged in a circular array, and the blades 2 is provided with a gradient edge 21; the fastening hole 3 is arranged on the blade body 1 and is located in the center of the blade body 1, and the inner edge of the fastening hole 3 is provided with an anti-vibration rubber ring 31, and the material of the anti-vibration rubber ring 31 is polyurethane; The monitoring recorder 4 is arranged at the bottom of the knife body 1, embedded and connected in the groove of the knife body, and the monitoring recorder 4 contains a miniature vibration sensor, a miniature temperature sensor and a miniature data memory.

[0015] When the spline milling cutter is actually working, it is fixed on the tool holder of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com