Dual-drive skid revolving joint portion dual-shaft parallel high-speed accurate mainshaft head

A spindle head, dual-drive technology, used in drive devices, metal processing machinery parts, metal processing equipment, etc., can solve the problems of not too high feed speed, few passive joints, small working space, etc., and improve the rigidity of the rotary guide. and accuracy, the effect of improving the force condition and improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

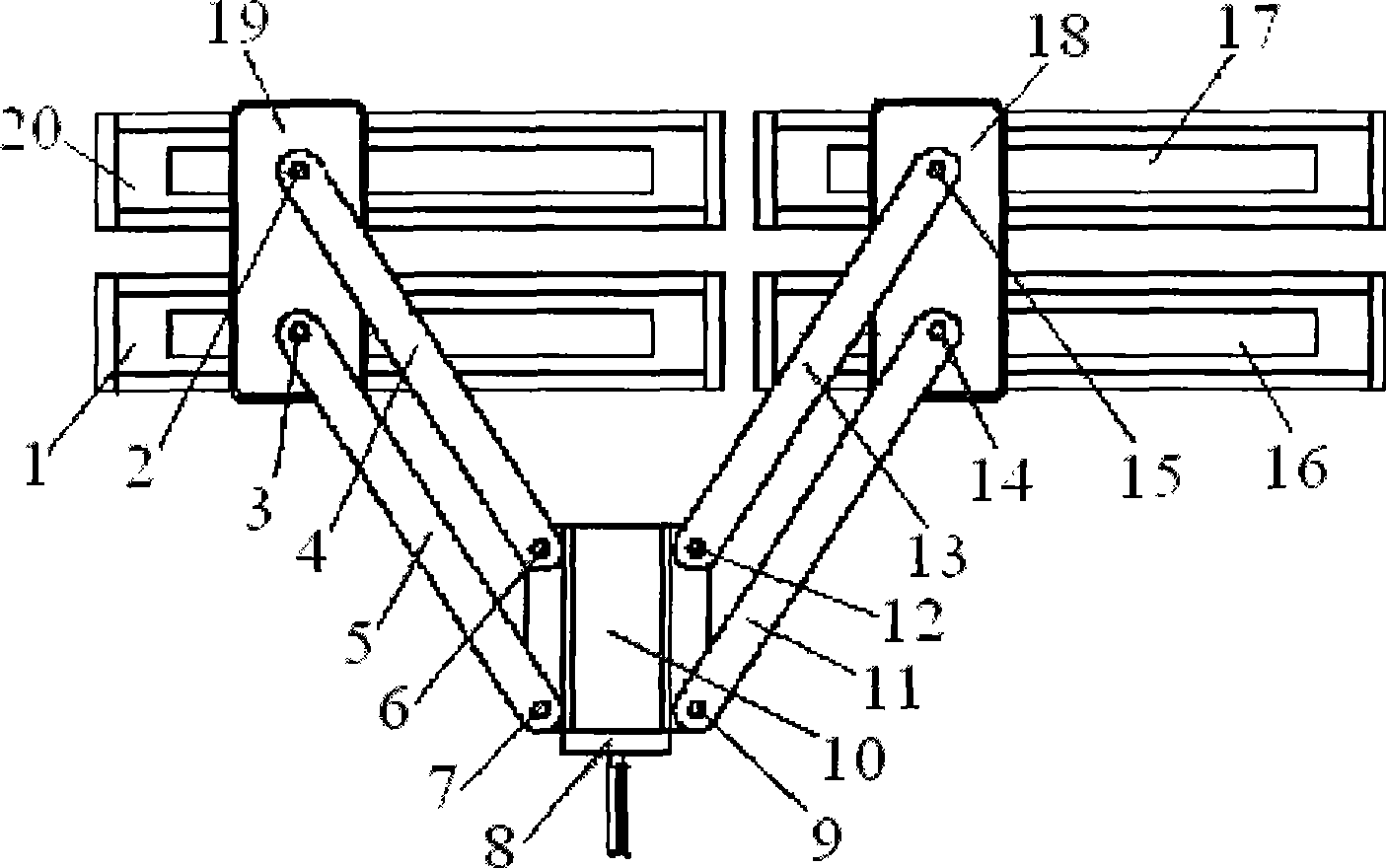

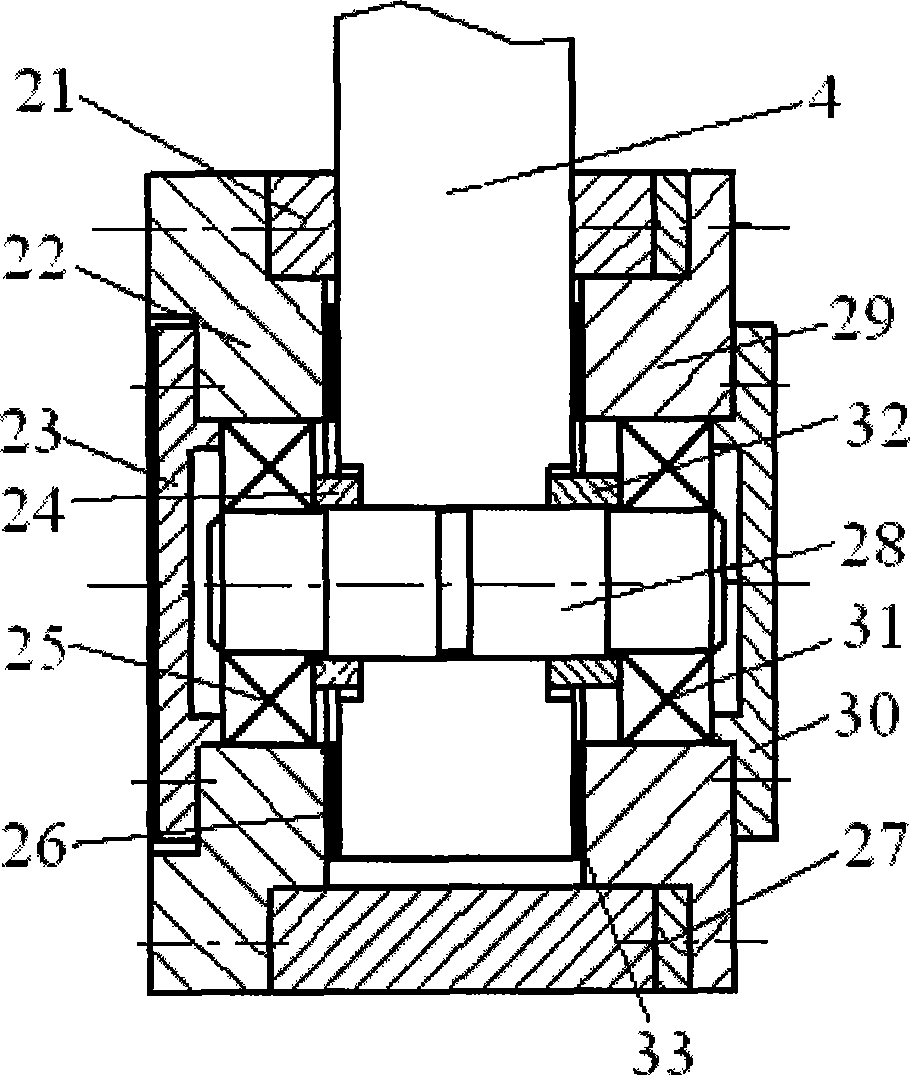

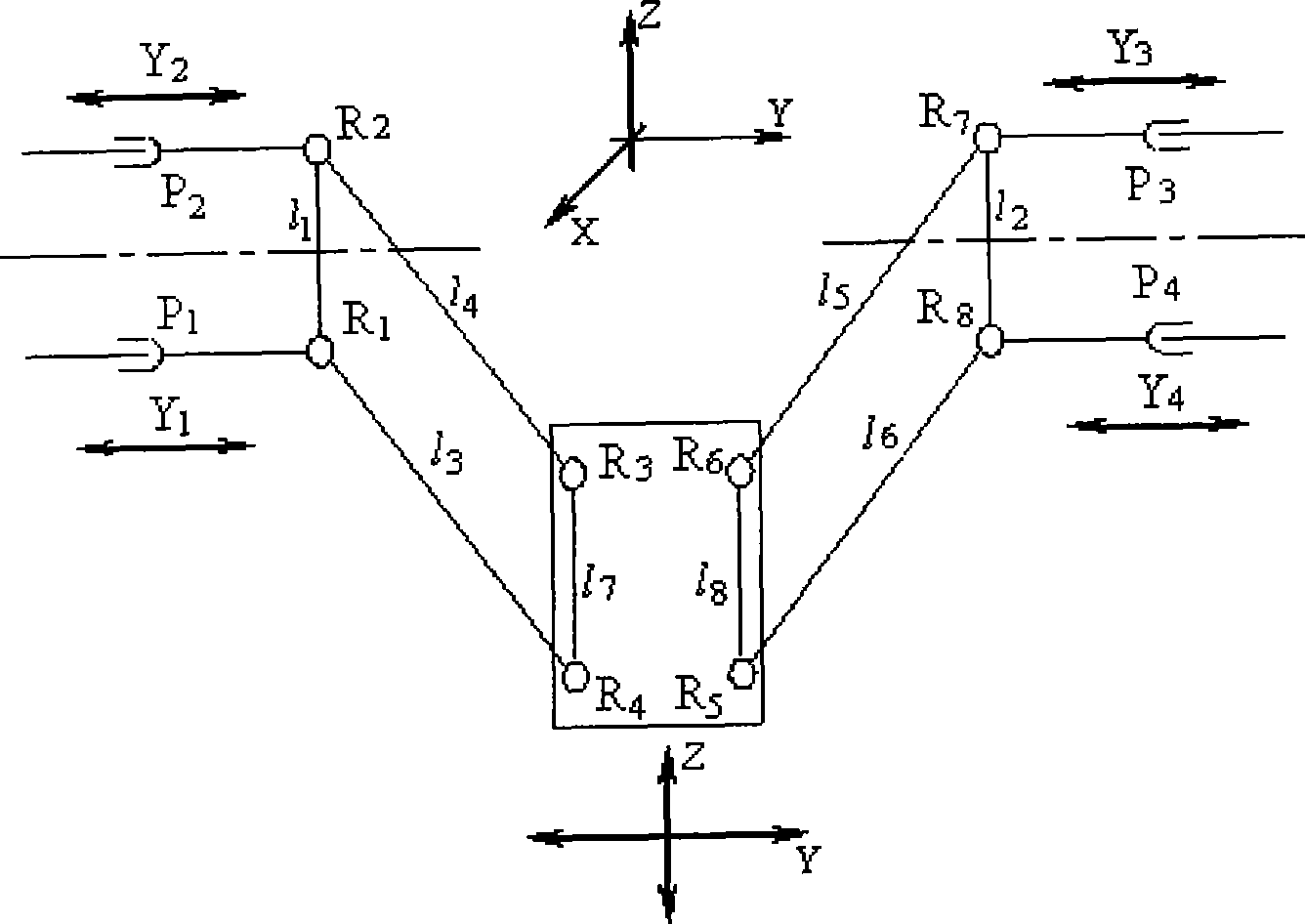

[0020] The structure of the spindle head of the present invention, such as figure 1 shown. Including linear motion assembly D20 and linear motion assembly C17 arranged horizontally side by side and linear motion assembly A1 and linear motion assembly B16 arranged horizontally side by side, linear motion assembly D20 and linear motion assembly A1 are arranged side by side, linear motion assembly C17 and linear motion assembly B16 set side by side. The sliders of the linear motion assembly D20 and the linear motion assembly A1 are respectively connected with the sliding table B19, the sliding table B19 can move along the sliding seats of the linear motion assembly D20 and the linear motion assembly A1, the sliding blocks of the linear motion assembly C17 and the linear motion assembly B16 The blocks are respectively connected with slide table...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com