Rolling sliding vane air compressor without oil lubrication

An oil-free lubrication and sliding vane technology, applied in the field of air compressors, can solve the problems of sliding vane wear, easy breakage, low strength, etc., and achieve the effect of reducing wear of parts, reducing power consumption and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

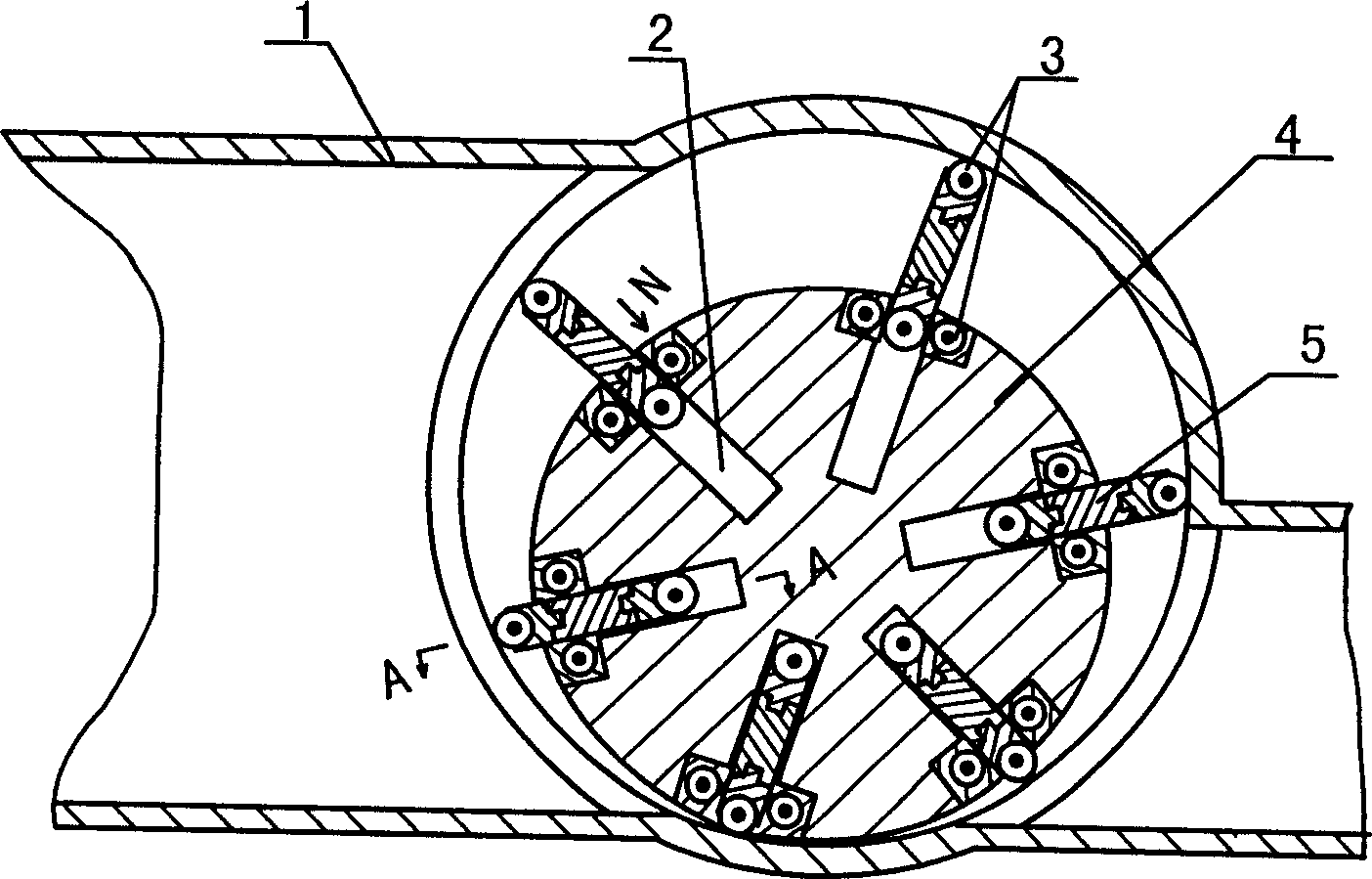

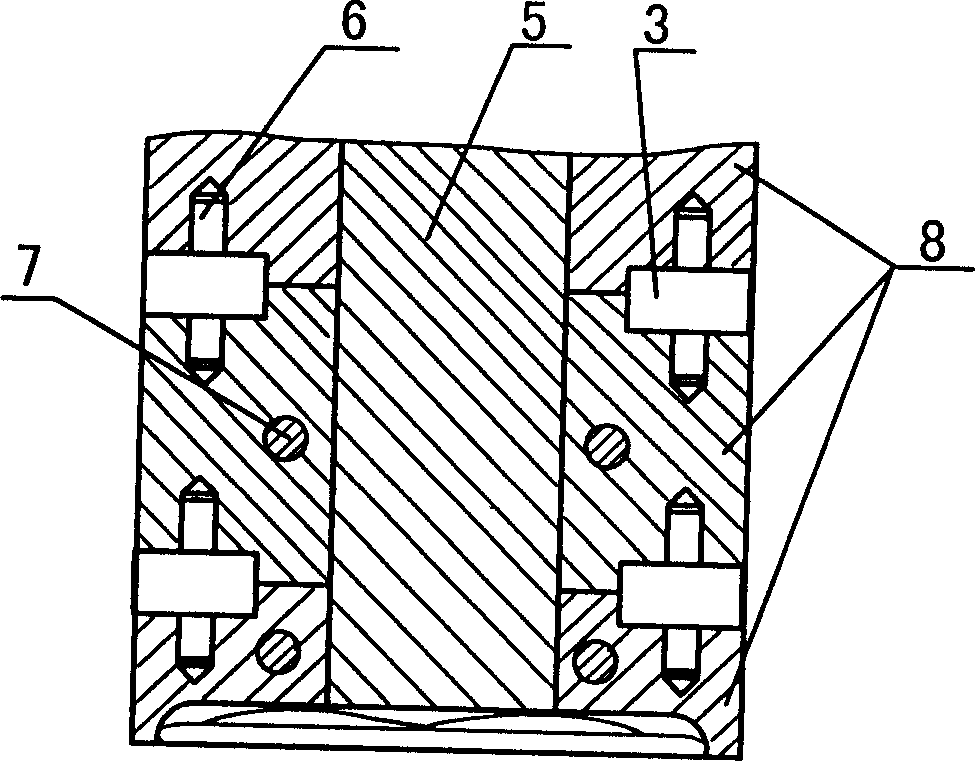

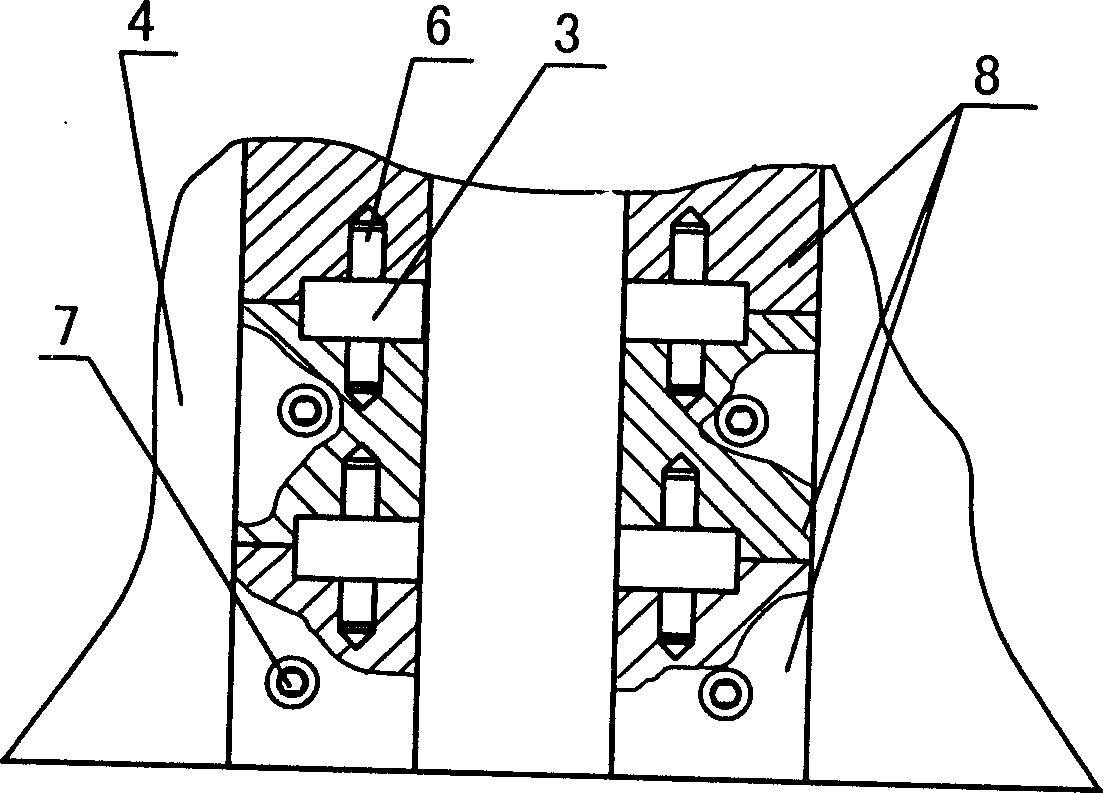

[0012] Such as Figure 1 to Figure 3 As shown, the present invention includes a cylinder 1 and a rotor 4, the rotor 4 is eccentrically installed in the cylinder 1, the rotor 4 is geometrically tangent to the cylinder 1, a crescent-shaped space is formed between the inner wall of the cylinder 1 and the outer surface of the rotor 4, and the rotor 4 is provided with rotor slots 2, and in each rotor slot 2 there is installed a sliding piece 5 that can slide freely in the radial direction, wherein the sliding piece 5 is made of aluminum alloy, its top and bottom and the rotor slot 4 Bearing housings 8 are installed on both sides, and rolling bearings 3 are installed on the bearing housings 8. The bearings 3 are filled with high-temperature resistant lubricants and have sealing rings. The friction between the sliding plate 5 and the inner wall of the cylinder 1 and the rotor 4 is rolling friction.

[0013] Specific installation method:

[0014] A. Installation of bearing housing 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com