Experiment test device and experiment test method of radial-axial ring rolling

A testing device and testing device technology, applied in length measuring devices, metal processing equipment, metal rolling, etc., can solve the problems of lack of experimental equipment, parameter errors, and difficult experiments, and achieve simple and convenient experimental operation, safe and reliable use. , The effect of the compact structure of the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

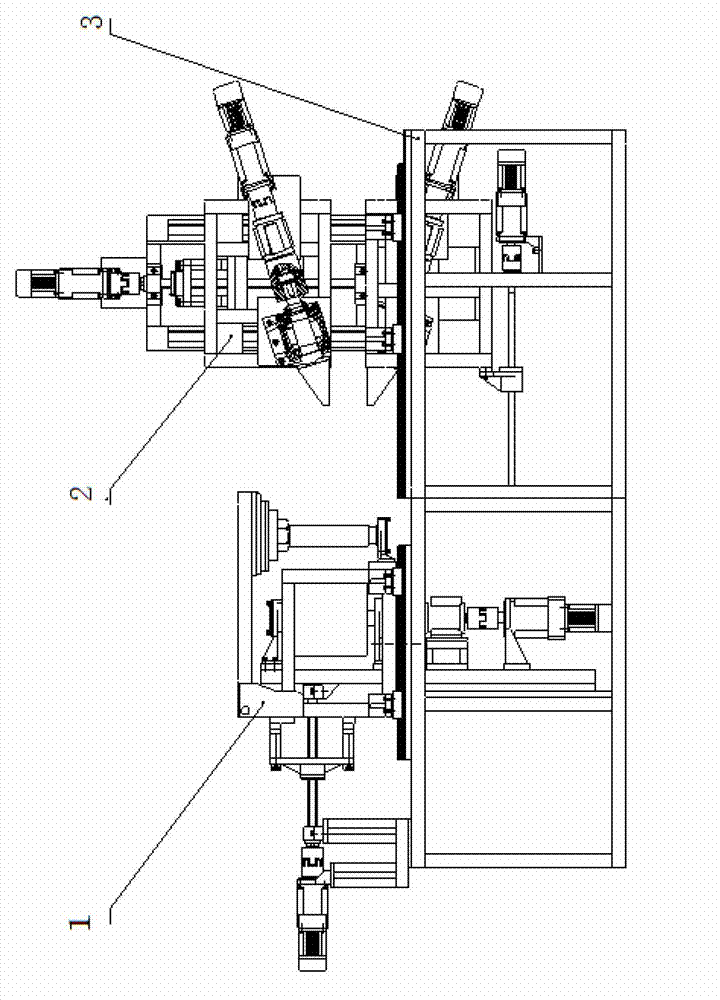

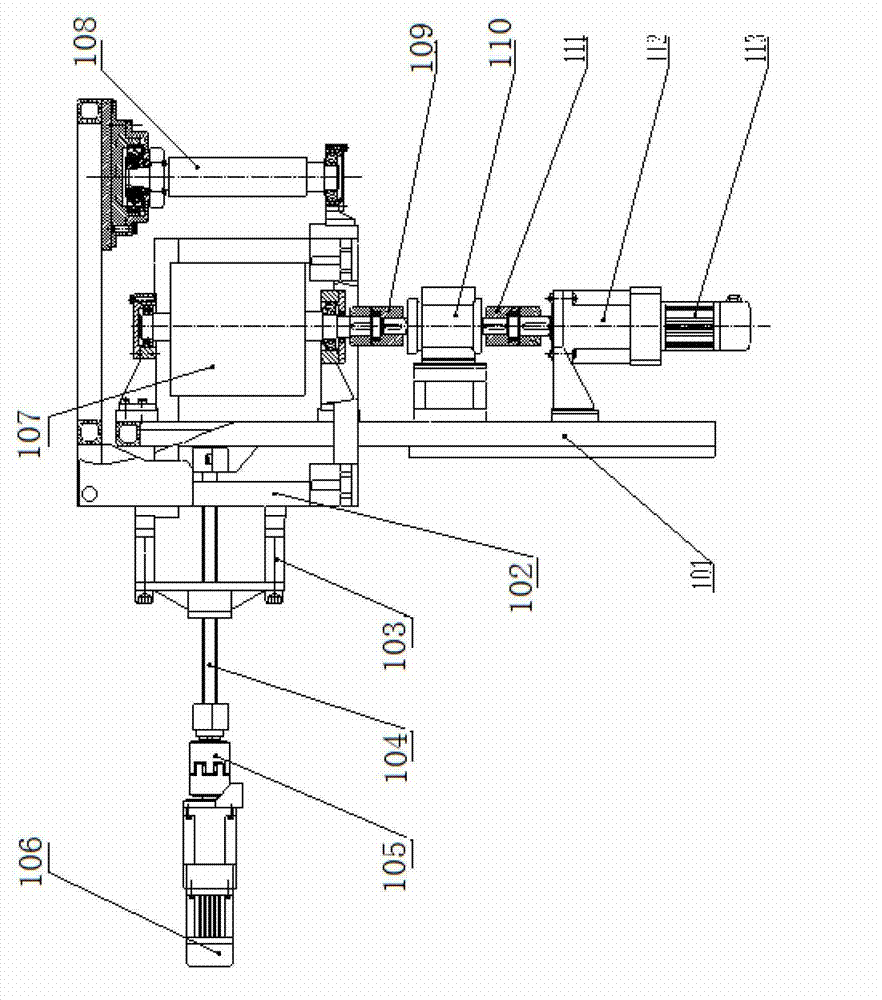

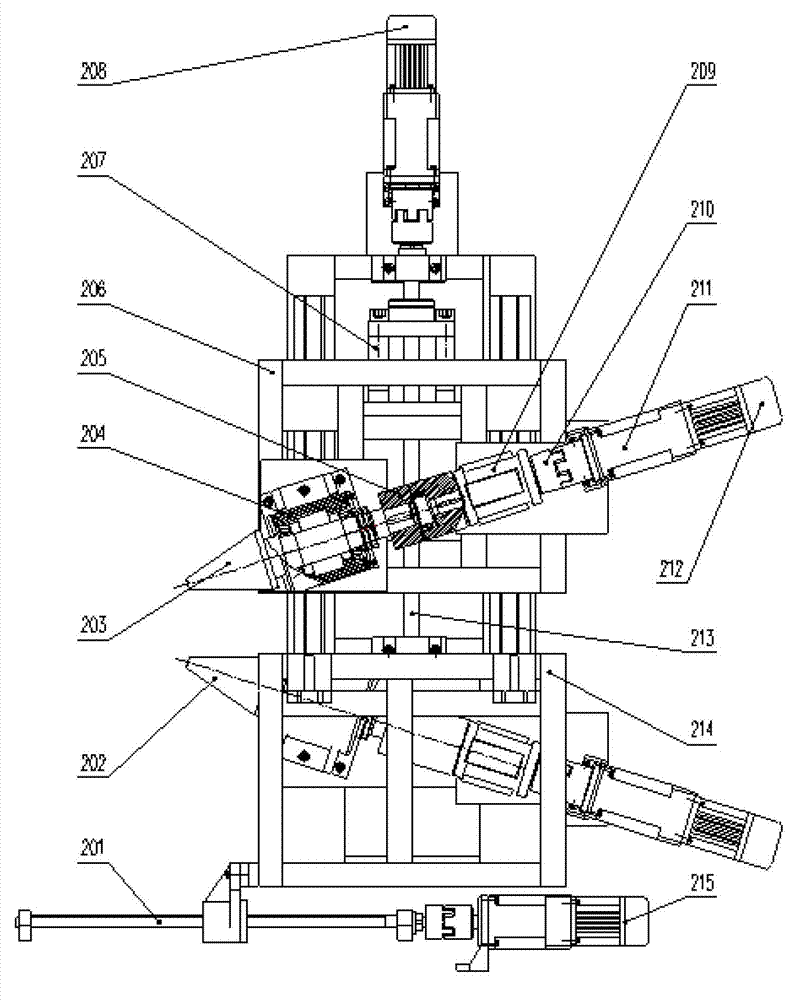

[0050] A radial-axial ring rolling experimental test device, such as figure 1 As shown, it is mainly composed of a radial rolling mechanism 1, an axial rolling mechanism 2 and a stand 3. Both the radial rolling mechanism 1 and the axial rolling mechanism 2 are installed on the stand 3 through guide rail sliders. The machine base 3, the axial frame and the frame of the radial rolling mechanism 1 are all welded by square steel, and the entire installation combination of the device is connected by bolts. The radial rolling mechanism 1 is mainly composed of a main roll device and a core roll device. The radial rolling mechanism 1 is equipped with a torque sensor I110 and a pressure sensor I103, which are used to detect the radial rolling force and diameter generated during the rolling process. to the rolling torque. Axial rolling mechanism 2 is mainly composed of upper and lower tapered roller devices and upper tapered roller slider 206. Torque sensor II 209 and pressure sensor I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com