Shedding cam vibration measuring device

A technology of vibration measurement and cam, which is applied in the direction of measuring device, vibration test, machine/structural component test, etc. It can solve the problem that it is impossible to determine whether the fault source of the opening mechanism is the opening cam, it is difficult to find out the cause of the vibration, and it is impossible to accurately judge the opening Cam quality and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

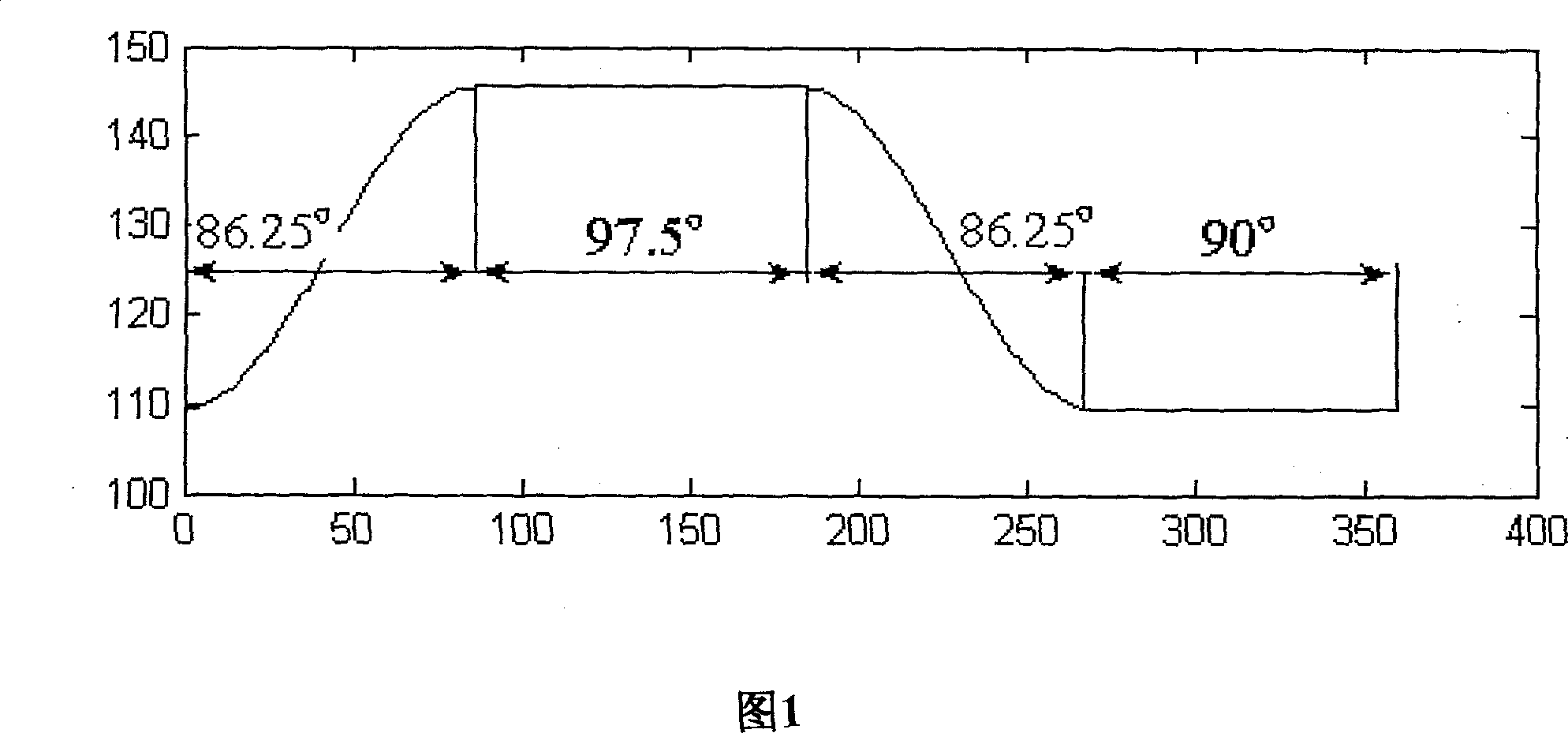

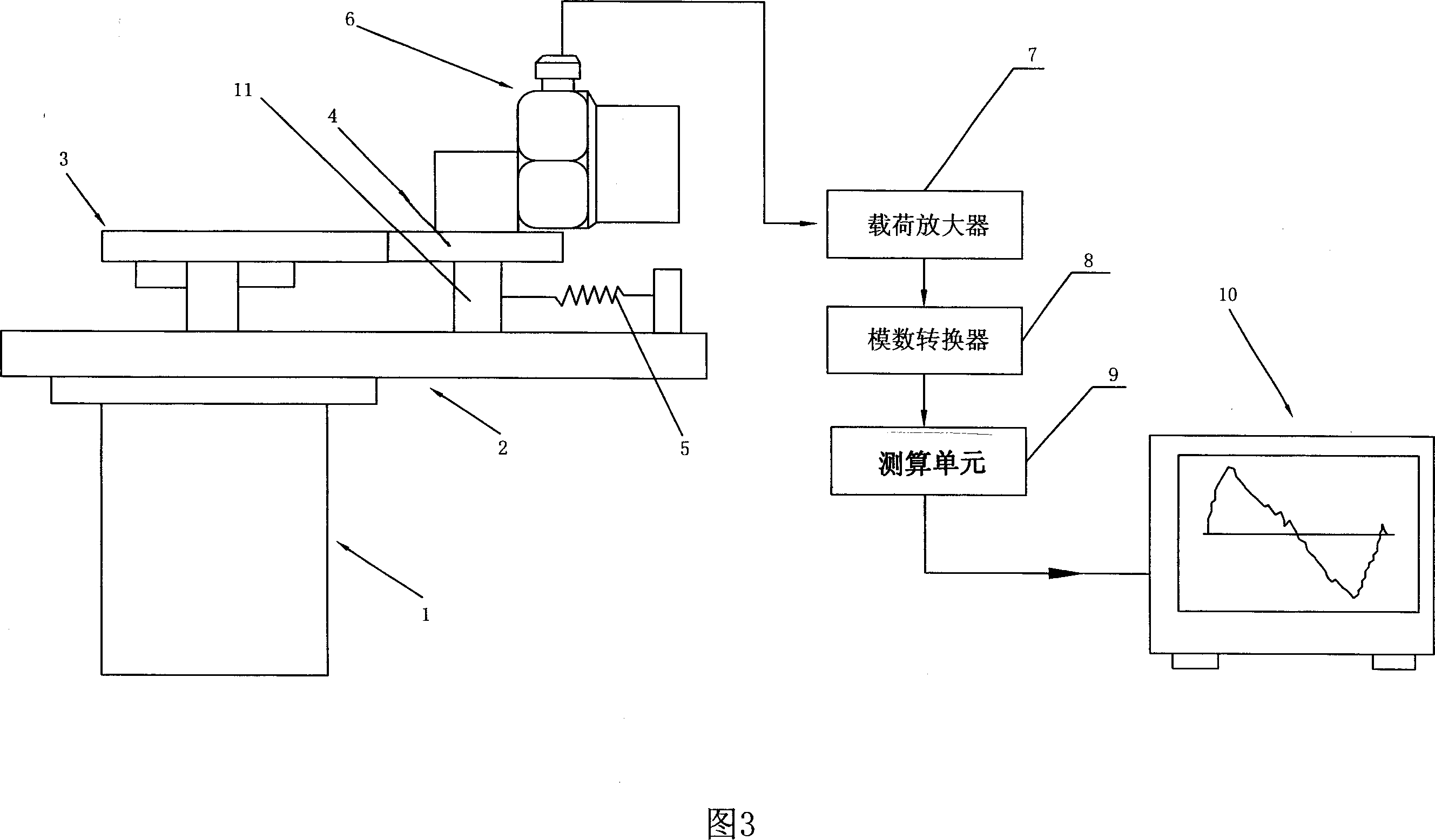

[0018] Referring to accompanying drawing 3-shown in accompanying drawing 4, a kind of vibration measurement device of opening cam, comprises installation platform 2, the opening cam 3 that is pivotally connected on described installation platform 2, is arranged on described installation platform 2 The servo motor 1, the output shaft of the servo motor 1 is connected with the opening cam 3 by key phase transmission, the installation platform 2 is provided with a slide groove 12, and a pin is slidably arranged in the slide groove 12 shaft 11, the pin shaft 11 is coaxially fixedly connected with the roller follower 4, the axis line of the roller follower 4 is parallel to the axis line of the rotating shaft of the opening cam 3, and the The sliding groove 12 is also provided with a spring 5, and the spring 5 provides a pressing force to the pin shaft 11, so that the outer peripheral surface of the roller follower 4 is pressed against the contour surface of the opening cam 3.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com