Efficient automatic welding device and welding system based on prefabricated cement board reinforcing steel bar welding

An automatic welding and cement board technology, which is applied in the direction of welding equipment, auxiliary equipment, auxiliary welding equipment, etc., can solve the problems of low welding efficiency and heavy workload of prefabricated slab steel bars, and achieve simple structure, saving labor intensity and practicality. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

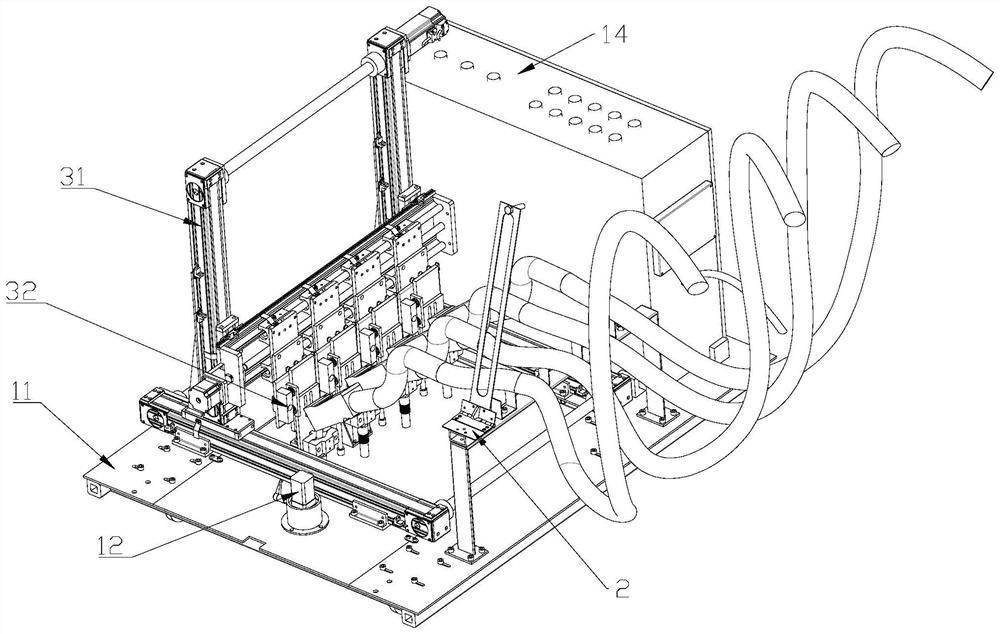

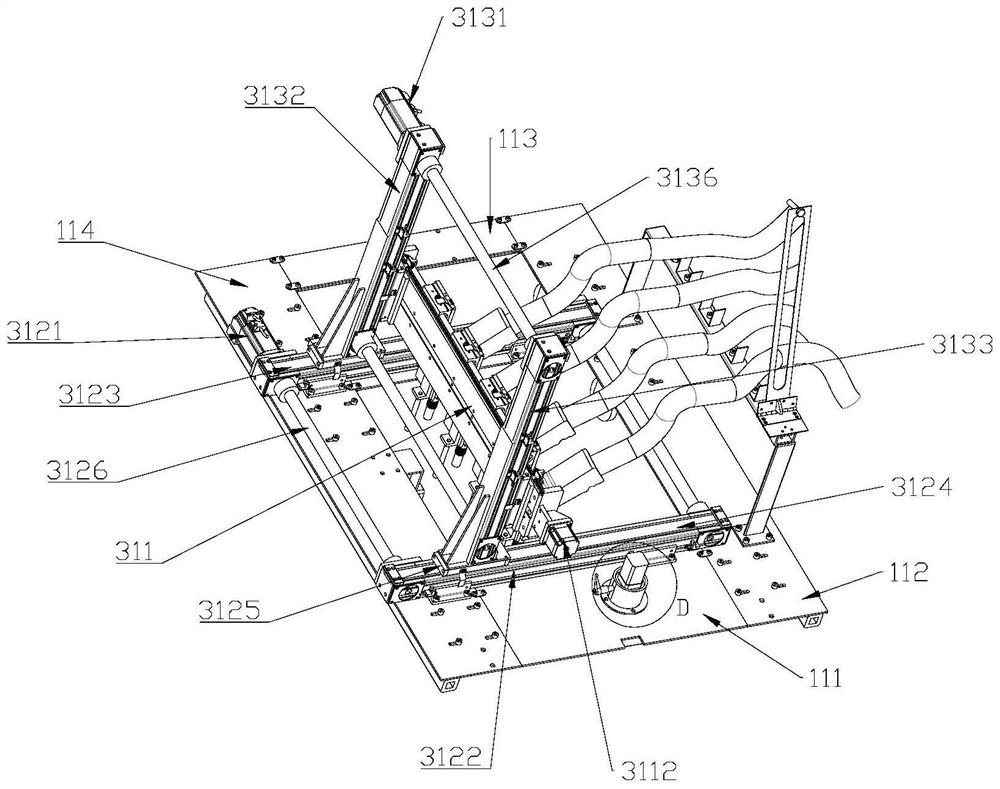

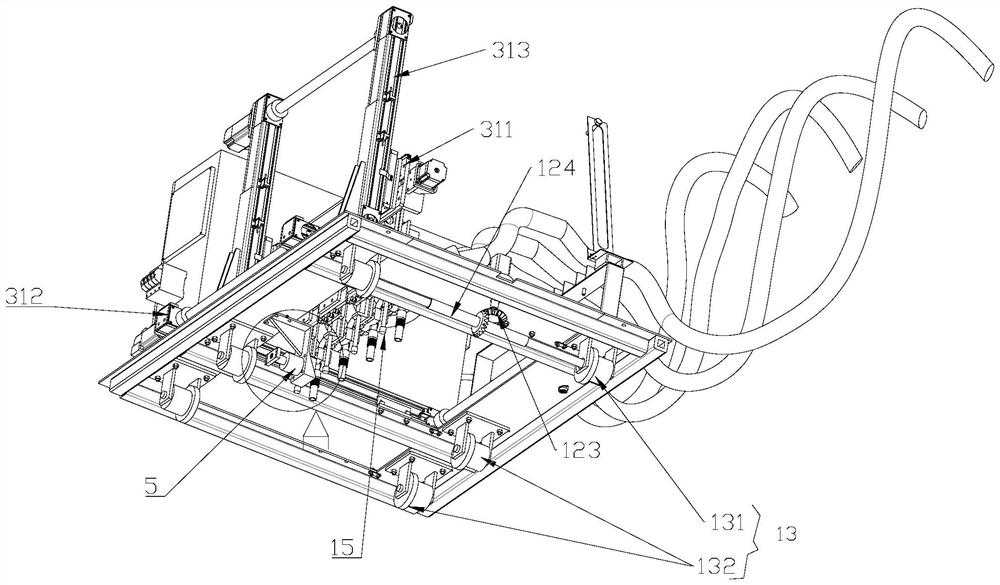

[0057] see Figure 1 to Figure 12, the present invention provides a high-efficiency automatic welding device based on prefabricated cement board reinforcement welding, including a welding car body 1, a cable clamping mechanism 2, a welding torch adjusting mechanism 3 and a welding torch clamping mechanism 4, wherein the welding torch adjusting mechanism 3 and the cable The clamping mechanisms 2 are all arranged on the welding car body 1, the welding torch clamping mechanism 4 is connected with the welding torch adjusting mechanism 3, and the welding torch adjusting mechanism 3 can drive the welding torch clamping mechanism 4 and the welding torch on the welding torch clamping mechanism 4 to move to the welding torch to be welded position of the weld seam.

[0058] Specifically, the welding torch adjustment mechanism 3 in this embodiment includes a three-dimensional motion mechanism 31 and a fine-tuning mechanism 32. The three-dimensional motion mechanism 31 is installed on the...

Embodiment 2

[0079] The difference between this embodiment and embodiment 1 lies in the fine-tuning mechanism, see Figure 17 ~ Figure 22 , the high-efficiency automatic welding device based on prefabricated cement board steel bar welding provided in this embodiment includes a welding car body 1, a cable clamping mechanism 2, a welding torch adjusting mechanism 3 and a welding torch clamping mechanism 4, a welding torch adjusting mechanism 3 and a cable clamping mechanism 2 are all arranged on the welding car body 1, and the welding torch clamping mechanism 4 is connected with the welding torch adjusting mechanism 3.

[0080] Wherein, the welding gun adjustment mechanism 3 includes a three-dimensional motion mechanism 31 and a fine-tuning mechanism 32, the three-dimensional motion mechanism 31 is installed on the welding car body 1, the fine-tuning mechanism 32 is connected with the three-dimensional motion mechanism 31, and the fine-tuning mechanism 32 includes a slide rail connecting bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com