Bi-directional mechanical relieving labor-saving mechanism for parking brake of railway vehicles

A technology for parking brakes and rail vehicles, which is applied in the field of rail vehicle parking brake relief. It can solve problems such as inconvenient operating positions, potential safety hazards, and large parking brake relief force, and achieves reduced mechanical release tension, good reliability, and The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

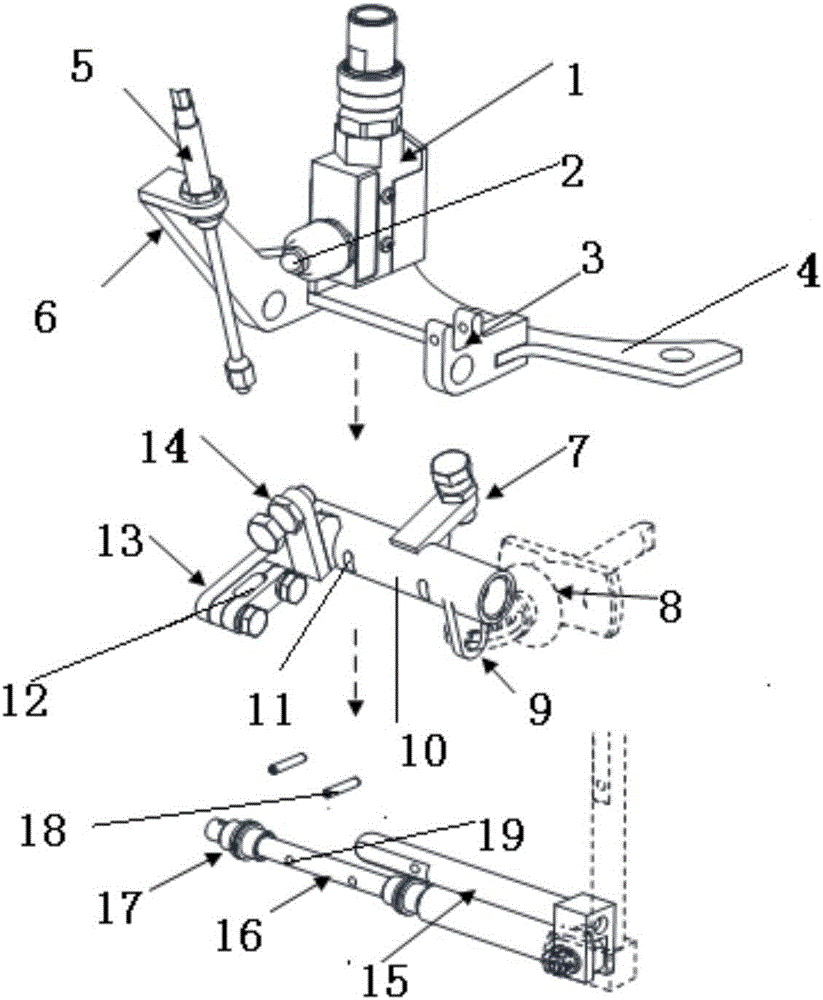

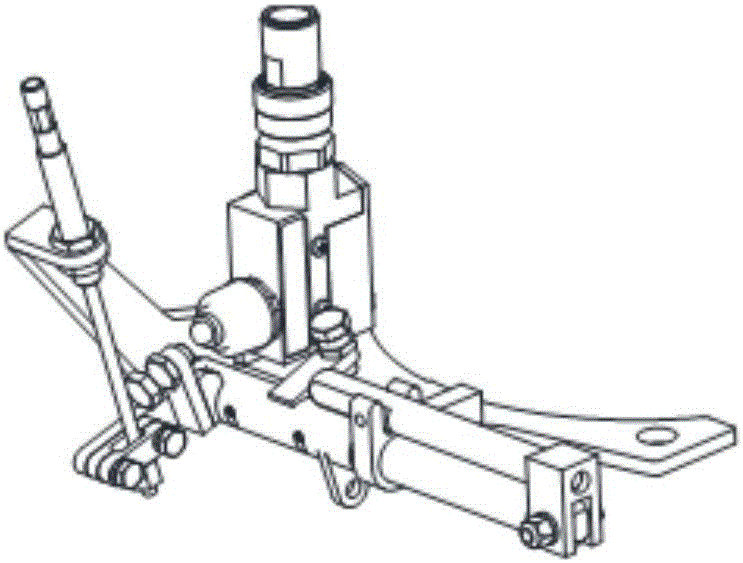

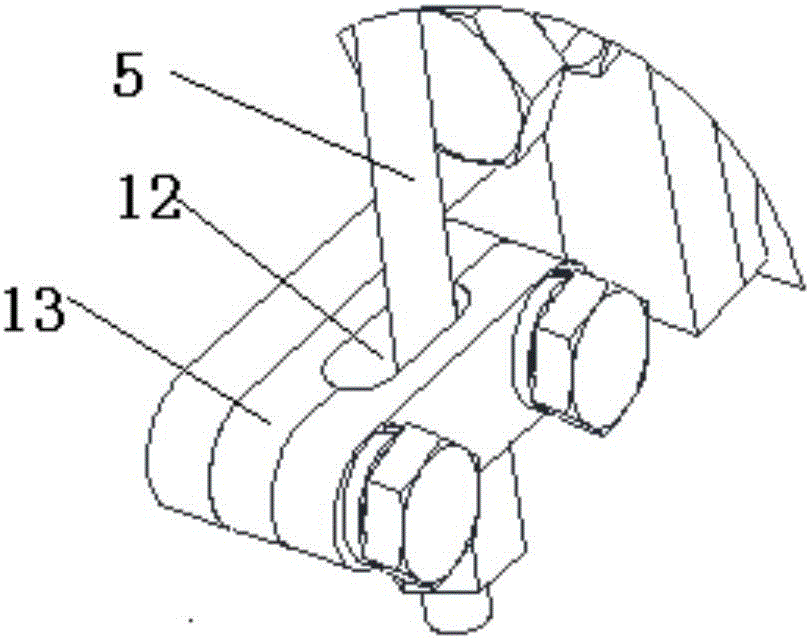

[0011] refer to figure 1 , figure 2 , the specific embodiment of the present invention comprises mounting plate 4, sleeve 10, rotating shaft 16, large and small force arms 13,9, adjustable limit stopper 7, transmission pin 18, operating handle 15 and travel switch 1 under the vehicle, and the mounting plate is used To fix the entire relief mechanism on the brake cylinder, the support plate 6 and the handle fixing clip 3 are all fixed on the mounting plate 4, and the travel switch is mounted on the mounting plate by screws. The sleeve 10 is installed on the shaft sleeve 17 of the rotating shaft 16, and is used to transmit the action of the push-pull cable 5. The sleeve 10 is provided with four oblong holes 11 in two pairs, the large and small moment arms 13, 9, and the travel switch trigger point 14 , Adjustable limit stops 7 are all fixed together with the sleeve 10. The big arm 13 is used to connect the push-pull steel cable, and the small moment arm is used to connect the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com