Carbonized city garbage fuel block preparation method and its dedicated apparatus

A municipal waste and carbonization technology, applied in the direction of fuel, solid fuel, biofuel, etc., can solve the problems of large composting equipment, difficult operation and complicated process technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

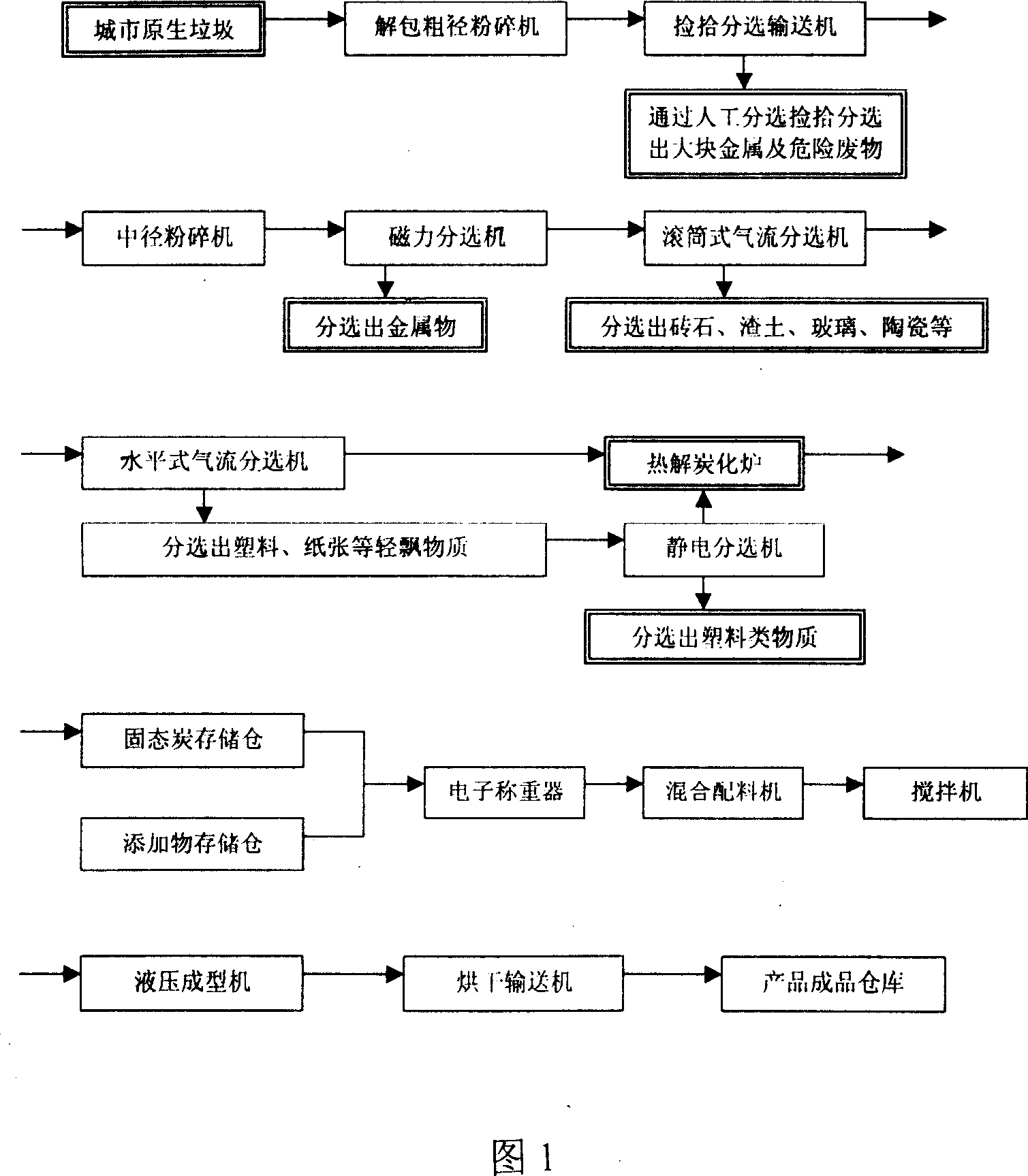

[0109] The method for producing fuel by carbonizing municipal waste of the present invention is realized through four process steps of sorting treatment, pyrolysis and carbonization treatment, batching and stirring treatment, forming and drying treatment.

[0110] 1. Sorting process

[0111] It mainly includes two aspects:

[0112] The first aspect is: through strict sorting and treatment, the inorganic substances such as masonry, slag, glass, ceramics, and metals contained in urban primary garbage are eliminated.

[0113] The above-mentioned inorganic substances cannot be pyrolyzed and carbonized. If it cannot be eliminated through strict sorting and treatment, and continues to be wrapped in urban primary waste and simultaneously participate in pyrolysis treatment, it will inevitably greatly increase the total quantity burden of pyrolysis treatment of urban primary waste, occupying the limited working volume of the pyrolysis and carbonization furnace; As a result, the energ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com