Comb type carboxylate ternary copolymer and preparation technology thereof

A technology of terpolymer and carboxylate, which is applied in the field of copolymer dispersants and comb-type carboxylate terpolymer dispersants, which can solve the problems of difficulty in controlling the molecular weight of dispersants, high viscosity of the system, and production costs. Expensive and other issues, to achieve the effect of being suitable for industrial scale production, simple preparation process and good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

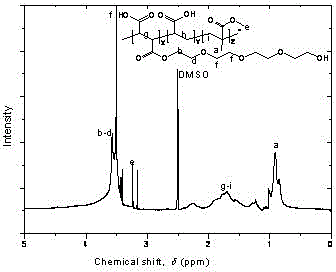

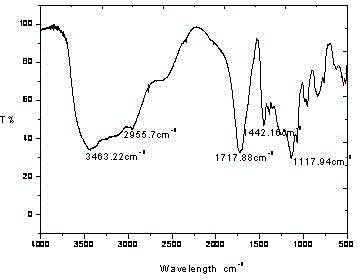

Image

Examples

Embodiment 1

[0034] 1) Preparation of dispersant:

[0035] Add 1000 parts of double-distilled water and 10 parts of surfactant into a four-necked reaction flask, and heat while stirring; when the temperature of the solution in the reaction flask rises to 60°C, add 200 parts of acrylate, 500 parts of acrylic acid 100 parts of monopolyethylene glycol monomethyl ether maleate and 30 parts of initiator solution were added within 1 hour, and then kept at 60°C for 2 hours; And the carboxylic acid in the system, the neutralization amount is 50% of the carboxyl molar number, makes the target dispersant solution.

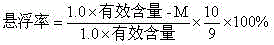

[0036] 2) Determination of the dispersibility of the prepared dispersant to inorganic minerals:

[0037] Add 0.4 g of the dispersant prepared in step (1) and 50 ml of distilled aqueous solution to a 100 ml stoppered measuring cylinder, add 1.00 g of solid particles to be dispersed after the dispersant is dissolved, then add the aqueous solution to 100 ml, within 1 min Upside down 30 ti...

Embodiment 2

[0047] Add 1000 parts of double distilled water and 80 parts of surfactant into a four-necked reaction flask, and heat while stirring; when the temperature of the solution in the reaction flask rises to 70°C, add 200 parts of acrylate, 200 parts of acrylic acid homolog Add 400 parts of monopolyethylene glycol monomethyl ether maleate and 60 parts of initiator solution within 5 hours, and then keep the heat for 3 hours; after the heat preservation reaction is completed, it is lowered to room temperature while stirring, and the system is neutralized with sodium hydroxide solution In the carboxylic acid, the neutralization amount is 80% of the carboxyl molar number, and the target dispersant solution is obtained.

[0048] By the operation procedure described in embodiment 1, record above-mentioned dispersant to the suspension rate of calcium carbonate suspension 98.54%, to the suspension rate of aluminum oxide suspension 98.29%, to the suspension of 600g / L imidacloprid aqueous sus...

Embodiment 3

[0050] Add 1000 parts of double distilled water and 20 parts of surfactant into a four-necked reaction flask, and heat while stirring; when the temperature of the solution in the reaction flask rises to 80°C, add 200 parts of acrylate, 500 parts of acrylic acid homolog 200 parts of monopolyethylene glycol monomethyl ether maleate and 60 parts of initiator solution are added within 2 hours, and then the heat preservation reaction is carried out for 5 hours; after the heat preservation reaction is completed, the temperature is lowered to room temperature while stirring, and the system is neutralized with sodium hydroxide solution In the carboxylic acid, the neutralization amount is 80% of the carboxyl molar number, and the target dispersant solution is obtained.

[0051] By the operation step described in embodiment 1, record above-mentioned dispersant to the suspension rate of calcium carbonate suspension 98.57%, to the suspension rate of aluminum oxide suspension 98.02%, to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| suspension rate | aaaaa | aaaaa |

| suspension rate | aaaaa | aaaaa |

| suspension rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com