Mobile phone identification code saw-tooth anti-counterfeiting method

A mobile phone identification and coding technology, which is applied in character and pattern recognition, computer components, data processing applications, etc., can solve problems such as customer returns, deactivation, printing quality defects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

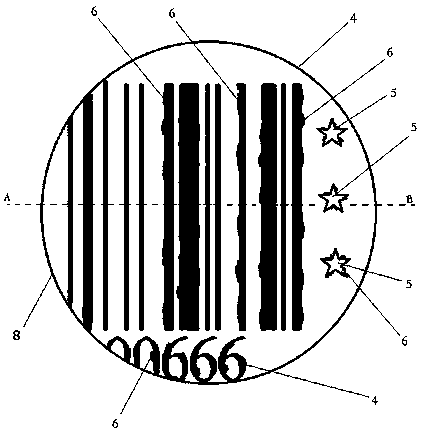

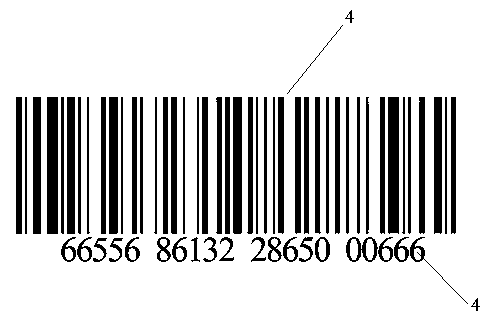

[0096] Embodiment 1: adopt the present invention to make a kind of medicine electronic supervisory code—code (4).

[0097] Such as figure 1 , Figure 5 , Figure 9 As shown, on the production line, printing machines (1) such as UV inkjet printers are used to spray codes on the conveyed medicine boxes and other substrates (2), so as to produce electronic drug supervision codes with personalized jagged edges (6) ——Coding (4), the coding (4) looks basically neat to the naked eye, meeting the C-level printing standard.

[0098] In order to promote the micro-deformation of the bars and characters of the drug electronic supervision code, a more significant individualized sawtooth edge (6) with a single sawtooth size (S)≥0.05mm(H)×0.05mm(W) is produced. An upper air gun can be set up between the inkjet printing machine (1) and the UV drying lamp (19), and the high-pressure air flow such as strong wind (11) can be blown to the undried electronic ink (3) sprayed by the wind. The p...

Embodiment 2

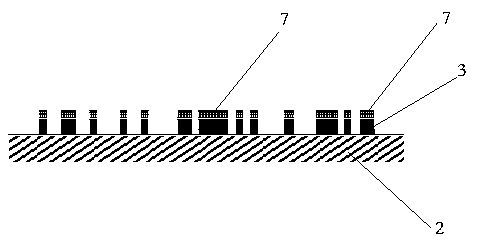

[0107] Embodiment 2: adopt the present invention to make a kind of drug electronic supervisory code—code (4).

[0108] Such as figure 1 , figure 2 , Figure 4 , Figure 10 As shown, on the printing line, inkjet printers (1) such as UV inkjet printers are used to spray codes on certain substrates (2) delivered, and the printed electronic inks (3) are used as cold stamping glue. Paste the silver laser cold stamping film (10), and then peel it off after being rolled by the pressure roller (9), so that the silver transfer layer (7) is transferred to the electronic ink (3), and a clear outline (without gradient color) is produced. ), some (not necessarily all) individual sawtooth size (S) ≥ 0.05mm (H) × 0.05mm (W) personalized serrated edge (6) drug electronic supervision code. The advantages of the drug electronic supervision code produced in this way are: the personalized jagged edge (6) has a clear outline, no gradient color, easy to automatically identify the anti-counterf...

Embodiment 3

[0113] Embodiment 3: Using the present invention to make a two-dimensional code whose content is the website address and serial number of the computer anti-counterfeiting network query system database. For example, the content is the QR code of http: / / t.ppk365.com / 436579352077, etc.

[0114] Such as Figure 5 , Figure 6 , Figure 9 As shown, on the printing line, an inkjet printer (1) such as a UV inkjet printer is used to spray code on the conveyed substrate (2), thereby producing a two-dimensional code with personalized jagged edges (6)— - Coding (4).

[0115] In order to promote the casting and micro-deformation of the two-dimensional code, a personalized sawtooth edge (6) is produced. An upper wind gun can be set up between the inkjet printer (1) and the UV drying lamp (19), and the strong wind (11) can be blown to the undried electronic ink (3) sprayed, and the two-dimensional The code is pushed by an external force to undergo slight deformation, thereby producing a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com