Alumina-based chemical mechanical polishing slurry

A chemical-mechanical, alumina-based technology, applied in the field of polishing fluid, can solve the problems of uneven dispersion of polishing fluid, poor quality of fine polishing, surface defects and scratches, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] In this embodiment, the chemical mechanical polishing liquid is 100 parts by weight, which contains the following raw material components and parts by weight:

[0041] 30 parts by weight of polishing particles

[0042] Surfactant 4 parts by weight

[0043] The balance is water and a pH adjuster.

[0044] The polishing particles described in this embodiment are aluminum oxide particles; the particle size is 150 nm; the pH regulator is nitric acid solution; the surfactant is sodium polyacrylate.

[0045] The pH of the chemical mechanical polishing solution is 3.

[0046] The chemical mechanical polishing fluid is obtained by stirring the above-mentioned raw material components evenly.

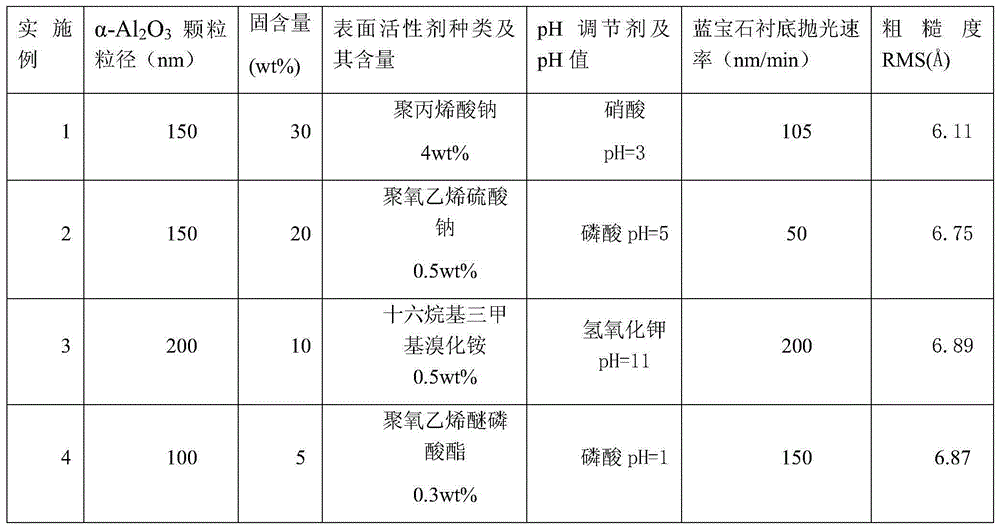

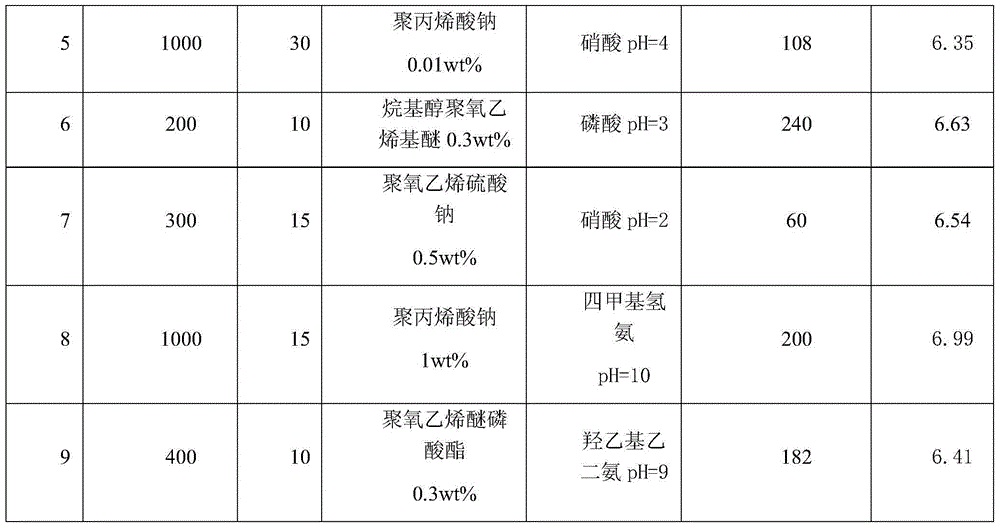

[0047] The polishing test results are shown in Table 1.

Embodiment 2

[0049] In this embodiment, the chemical mechanical polishing liquid is 100 parts by weight, which contains the following raw material components and parts by weight:

[0050] 20 parts by weight of polishing particles

[0051] Surfactant 0.5 parts by weight

[0052] The balance is water and a pH adjuster.

[0053] The polishing particles described in this embodiment are aluminum oxide particles; the particle size is 150 nm; the pH regulator is nitric acid solution; the surfactant is polyoxyethylene sodium sulfate.

[0054] The pH of the chemical mechanical polishing solution is 5.

[0055] The chemical mechanical polishing fluid is obtained by stirring the above-mentioned raw material components evenly.

[0056] The polishing test results are shown in Table 1.

Embodiment 3

[0058] In this embodiment, the chemical mechanical polishing liquid is 100 parts by weight, which contains the following raw material components and parts by weight:

[0059] 10 parts by weight of polishing particles

[0060] Surfactant 0.5 parts by weight

[0061] The balance is water and a pH adjuster.

[0062] The polishing particles described in this embodiment are aluminum oxide particles; the particle size is 200 nm; the pH regulator is potassium hydroxide; the surfactant is sodium polyoxyethylene sulfate.

[0063] The chemical mechanical polishing solution has a pH of 11.

[0064] The chemical mechanical polishing fluid is obtained by stirring the above-mentioned raw material components evenly.

[0065] The polishing test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com