Testing machine for simulating fatigue life in full scale mode in marine environment of harbor pipeline

A marine environment and fatigue life technology, applied in the direction of applying repeated force/pulsation force to test the strength of materials, etc., can solve problems such as inaccurate measurement, achieve accurate mechanical properties, and prevent cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

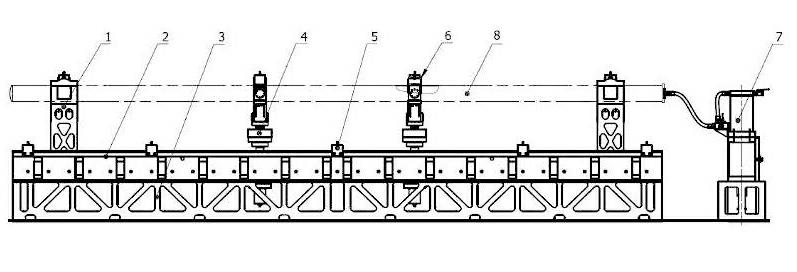

[0018] Two guide rail beams 2 are fixedly connected to the workbench 3, two mobile supports 1 are respectively slidably connected to the guide rail beam 2, two servo loading units 4 are respectively slidably connected to the guide rail beam 2, and the internal pressure loading unit 7 is fixed to the workbench 3 connect.

[0019] One embodiment of the present invention is that the buckle plate 5 is fixedly connected with the guide rail beam 2 .

[0020] One embodiment of the present invention is that the clip block 6 is respectively socketed with the inside of the clip ring in the mobile support 1 or the servo actuating mechanism 4 .

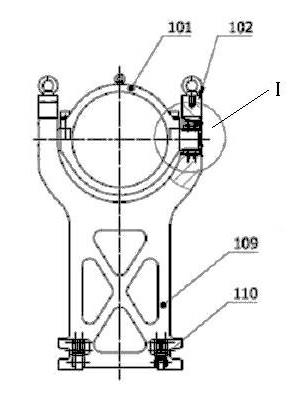

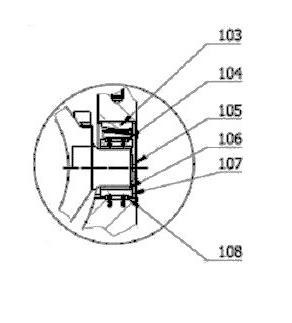

[0021] The structure of the mobile support of the present invention is: the support 109 is fixedly connected with the guide rail beam 2 through the top wire, the running mechanism 110 is slidably connected with the workbench 3, the clamp ring 101 and the support 109 are hinged together through the self-lubricating bearing 106, Self-lubricating b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com