Solid-state vertical fertilization, self-circulation cooling and distillation integrated device and method

A vertical fermentation tank and self-circulation technology, which is applied in the field of biological fermentation and distillation, can solve the problems of low utilization rate of fermentation equipment, high labor intensity of workers, and manual secondary handling, so as to reduce labor intensity, improve production efficiency, reduce The effect of loss such as volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention, but the present invention is not limited thereto.

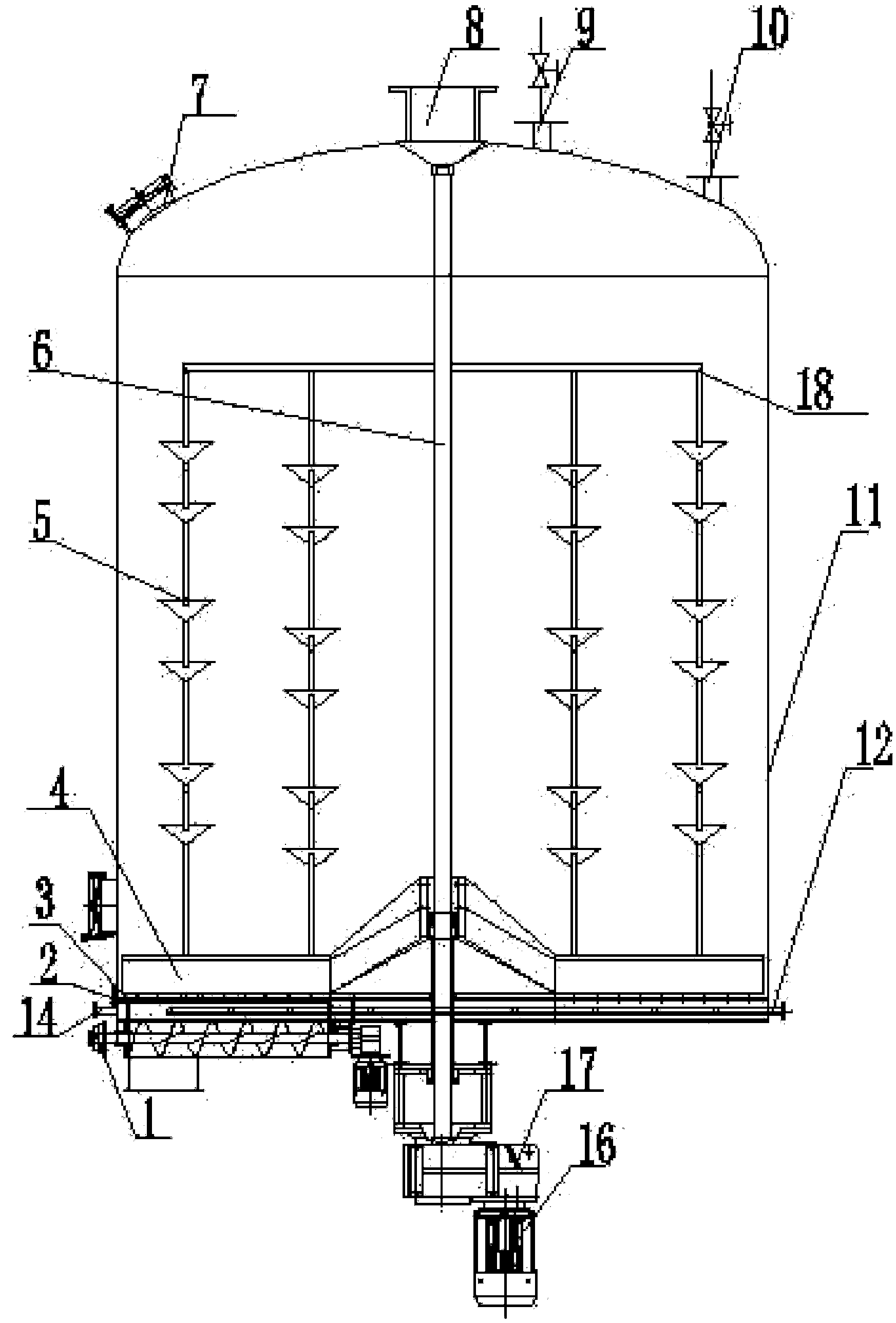

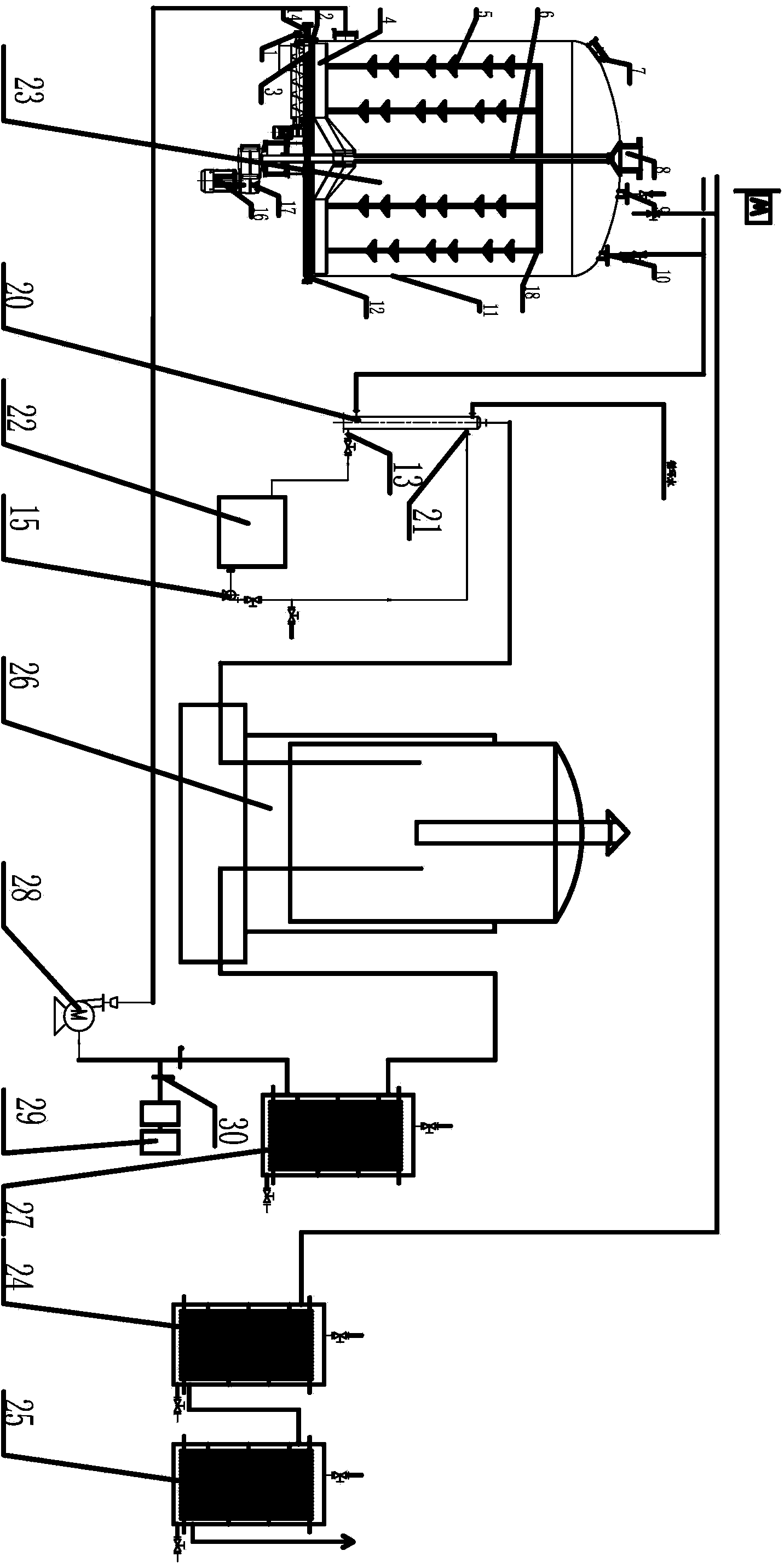

[0022] A solid-state vertical fermentation, self-circulation cooling, and distillation integrated device, including a solid-state vertical fermentation tank 23, a washing tower 20, a washing pump 15, a gas cabinet 26, a circulating gas cooler 27, a circulating fan 28, a filter 29, Distillation product cooler 24. Distillation product cooler 25. The solid-state vertical fermentation tank consists of a tank body 11, a stirring device arranged at the bottom of the tank, a discharge device, a feed inlet 8, a distillation product gas outlet 10, a biochemical reaction gas outlet 9, a manhole 7, and a discharge A rake 4, a distillation steam inlet 12, and a circulating gas cooling air inlet 14 are formed.

[0023] The char...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com