Tobacco formula uniformity regulating and controlling method

A uniformity, tobacco leaf technology, applied in the direction of tobacco, tobacco preparation, and collaborative operation devices, etc., can solve the problems of limited controllability, lack of initiative in formulation, strong active formulation ability, etc., to achieve uniformity and convenient prediction. Manage and reduce the effect of incense sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

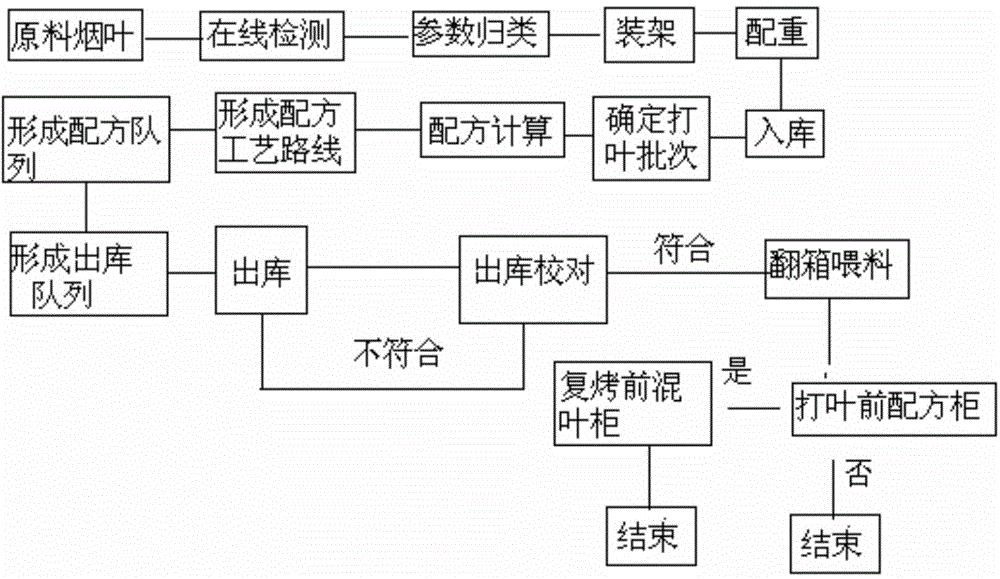

Method used

Image

Examples

Embodiment 1

[0056] This embodiment specifically discloses a method for regulating the mixing effect by regulating the uniformity of the nicotine value in the raw tobacco leaves.

[0057] 1) The raw tobacco leaves are scanned and detected under the detection equipment through the conveyor belt, and a full cigarette box is used as a detection unit, and the nicotine value of the cigarette box is detected and recorded. At the same time, the system classifies the detected nicotine values into the corresponding intervals according to the preset nicotine value interval division rules, marks them, and transmits them to the elevated storage system.

[0058] 2) The scanned and detected tobacco leaves are loaded into the rack according to the preset weight in the racking process, and the weight of the tobacco leaves in each rack is guaranteed to be consistent through counterweighting. At the same time, the system writes the relevant information into the RFID tag on the cigarette box.

[0059] 3) T...

Embodiment 2

[0067] This embodiment specifically discloses a method for regulating the mixing effect by regulating the uniformity of total sugar in raw tobacco leaves.

[0068] Scanning and testing the raw tobacco leaves under the testing equipment to obtain testing parameters;

[0069] The value of the detection parameter is divided into several intervals, and the raw tobacco leaves whose value of the detection parameter falls into the same interval are of the same grade;

[0070] The raw tobacco leaves of the same grade are racked according to the set weight to obtain cigarette boxes, and each cigarette box is affixed with an RFID label recording the corresponding grade;

[0071] Place each smoke box on the elevated shelf of the elevated warehouse, and smoke boxes of the same level are evenly distributed on different elevated shelves;

[0072] According to the formula process route, the corresponding smoke box is transferred to the feeding bin for feeding and cabinet matching.

[0073]...

Embodiment 3

[0082] This embodiment specifically discloses a method for regulating the mixing effect by regulating the uniformity of total nitrogen in raw tobacco leaves.

[0083] Scanning and testing the raw tobacco leaves under the testing equipment to obtain testing parameters;

[0084] The value of the detection parameter is divided into several intervals, and the raw tobacco leaves whose value of the detection parameter falls into the same interval are of the same grade;

[0085] The raw tobacco leaves of the same grade are racked according to the set weight to obtain cigarette boxes, and each cigarette box is affixed with an RFID label recording the corresponding grade;

[0086] Place each smoke box on the elevated shelf of the elevated warehouse, and smoke boxes of the same level are evenly distributed on different elevated shelves;

[0087] According to the formula process route, the corresponding smoke box is transferred to the feeding bin for feeding and cabinet matching.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com