Design method of line unwinding constant tension control device in line winding system

A technology of a control device and a design method, which is applied in the directions of transportation and packaging, transportation of filamentous materials, and processing of thin materials, etc., can solve the problems of poor quality, limited amplitude of up and down swing, and broken wire diameter of braided wire B.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Aiming at the defects of the existing tension control device of the power pay-off machine, the present invention designs a design method of the tension control device of the power pay-off machine with a new structure to make it more practical.

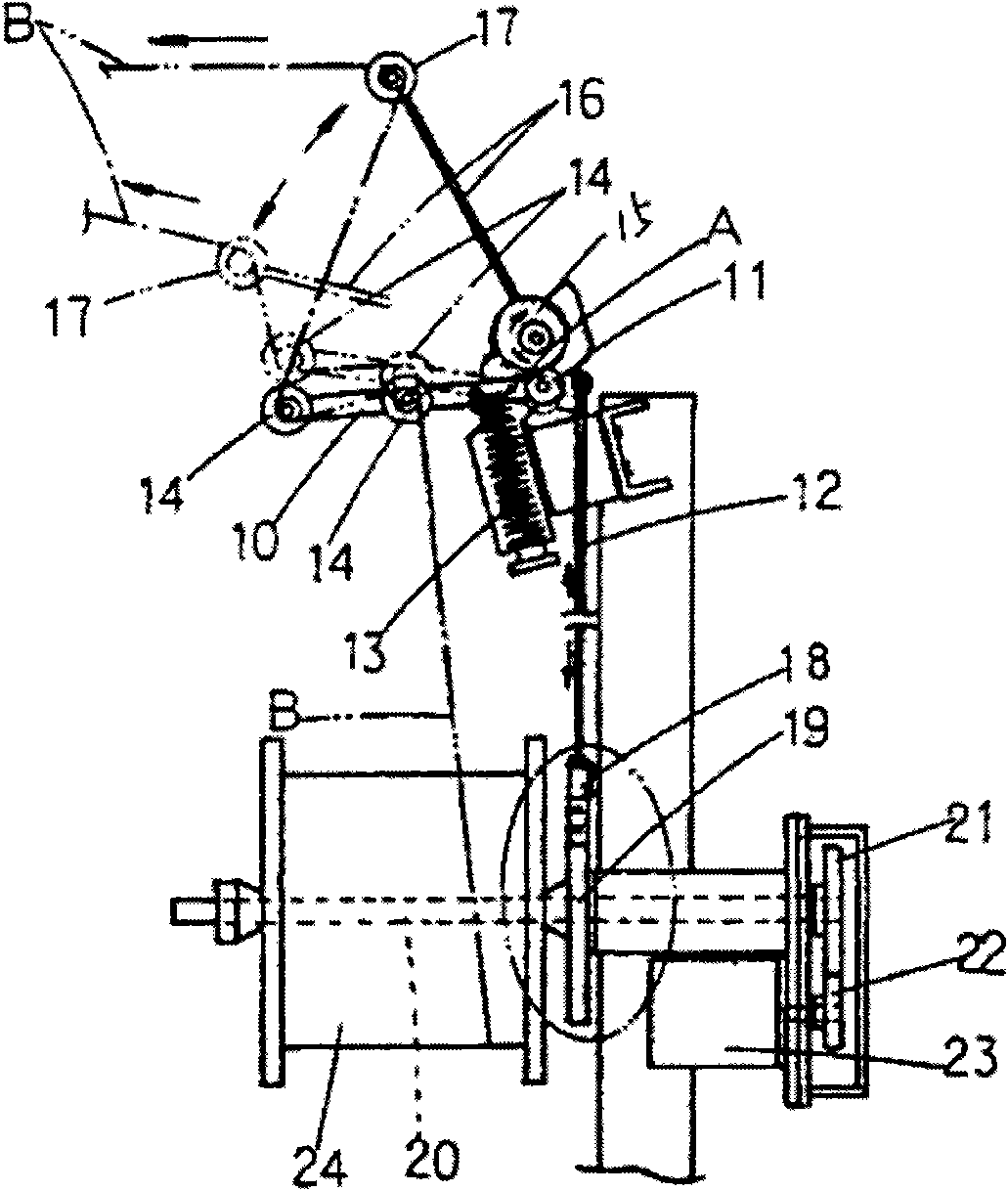

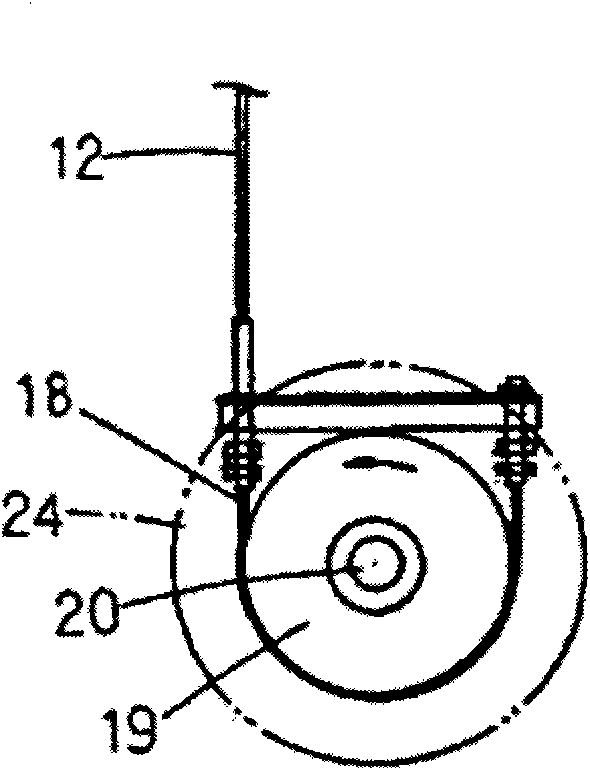

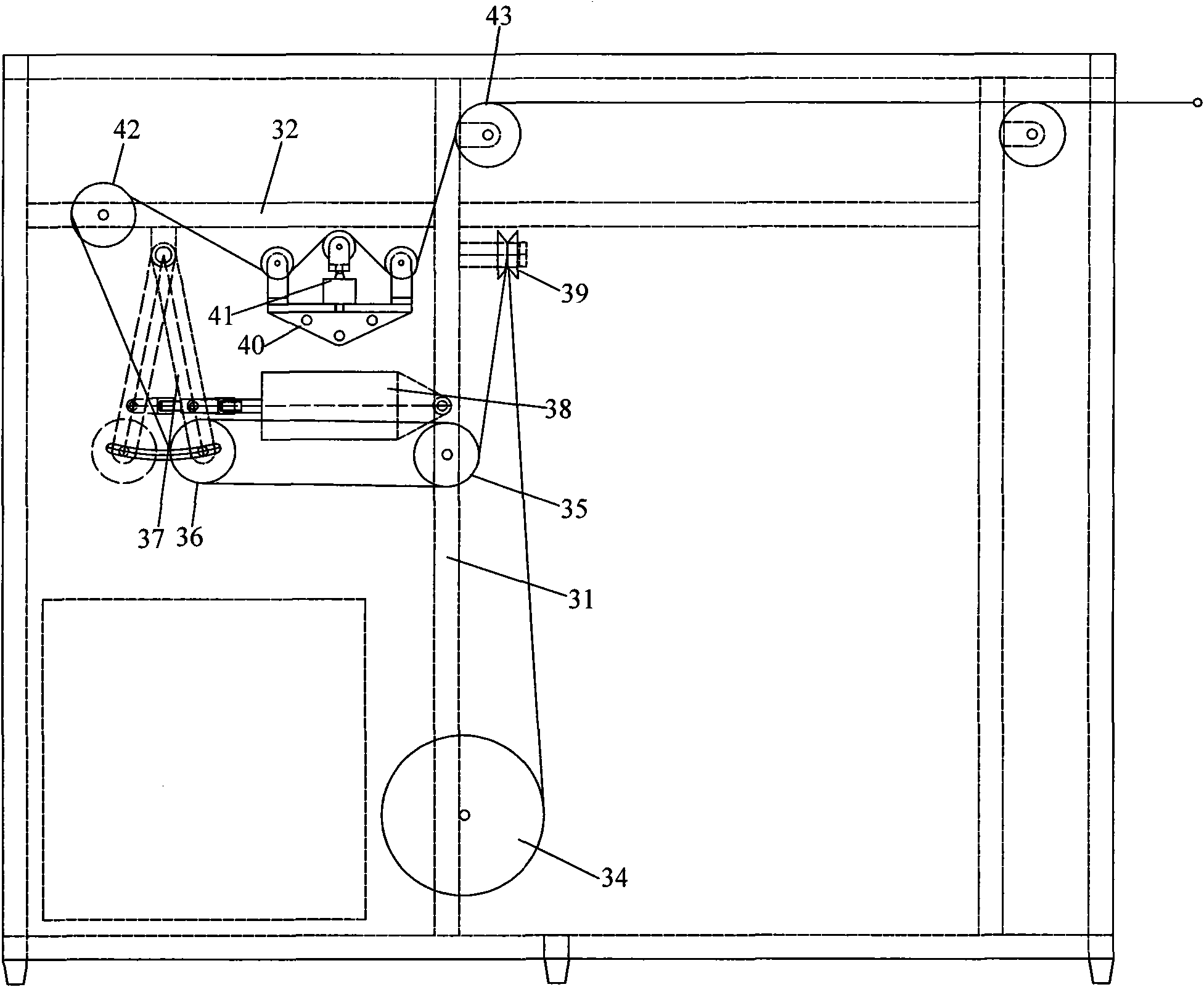

[0023] Such as figure 2 , image 3 As shown, the pay-off constant tension control device in the wire winding system can control the tension of one or more wire ropes. A servo motor 33 and a pay-off wheel 34 are installed at the bottom of the frame, and the servo motor 33 is driven by a drive element. Pay-off pulley 34, line is wound on the pay-off pulley 34; On the frame behind pay-off pulley 34, be provided with the pulley block of two fixed pulleys and a movable pulley, promptly the first fixed pulley 35 is installed on the side support 31, the second Two fixed pulleys 42 are installed on the upper bracket 32, the movable pulley 36 is between the first fixed pulley 35 and the second fixed pulley 42, the movable pulley 36 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com