Method for adjusting/reducing internal stress of laser additive manufacturing part

A laser additive and additive manufacturing technology, which is applied in the direction of additive manufacturing, additive processing, and improvement of process efficiency, can solve problems such as difficult control of internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

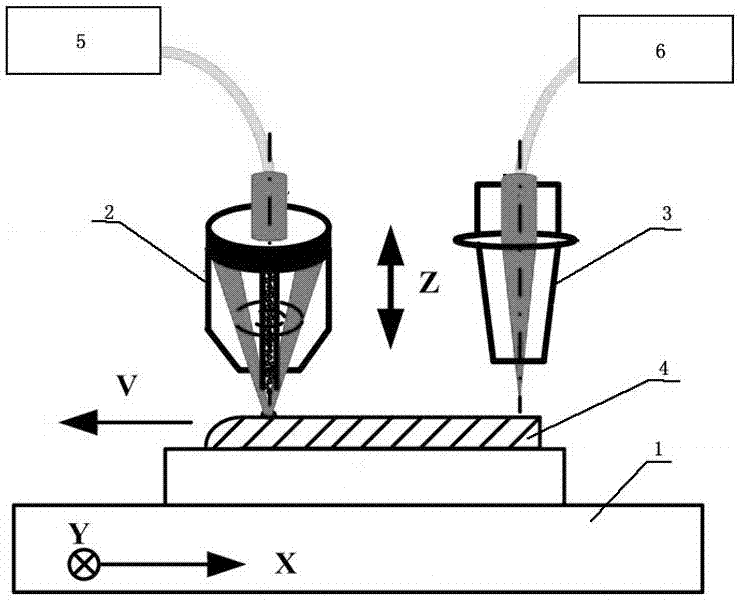

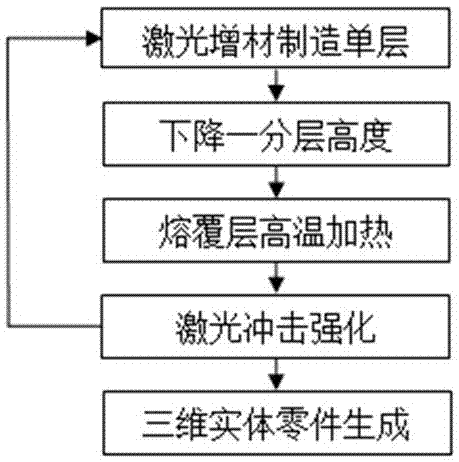

[0028] Embodiment one: see figure 1 and figure 2 As shown, a method for regulating / reducing the internal stress of laser additive manufacturing parts comprises the following steps:

[0029] (1) Use a computer to establish a thin-walled part model, and process the model layered through software to obtain the contour level information of the part.

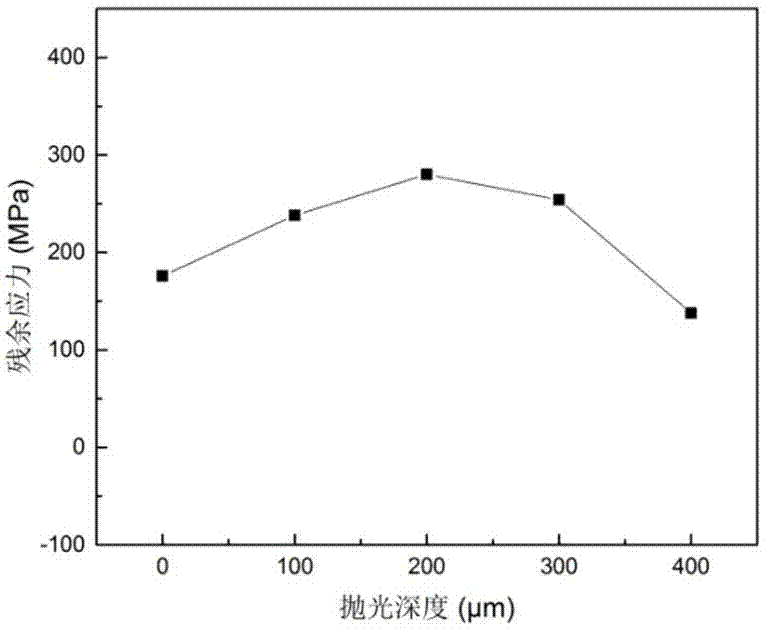

[0030] (2) The numerical control system is called to move the workbench 1 under the cladding head 2, and the cladding head 2 is provided with a laser beam by the fiber laser 5 to carry out coaxial powder feeding single-layer laser cladding to form the cladding layer 4 . In this embodiment, the experimental powder is 316L stainless steel, the particle size is 45 μm to 74 μm, the base material is 304 stainless steel, and the geometric size is 100 mm×100 mm×8 mm. Adopt laser power P=630W, powder feeding amount Mp=8g / min, scanning speed V=6mm / s, laser defocus amount is Z l =-3mm, and the process parameters of cladding length 30mm are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com