hrb500e niobium-titanium micro-alloy high-strength anti-seismic steel bar and its production process

A technology of anti-seismic steel bars and production technology, which is applied in the field of metallurgy to achieve the effects of reducing crack sensitivity, increasing safety reserves, and reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

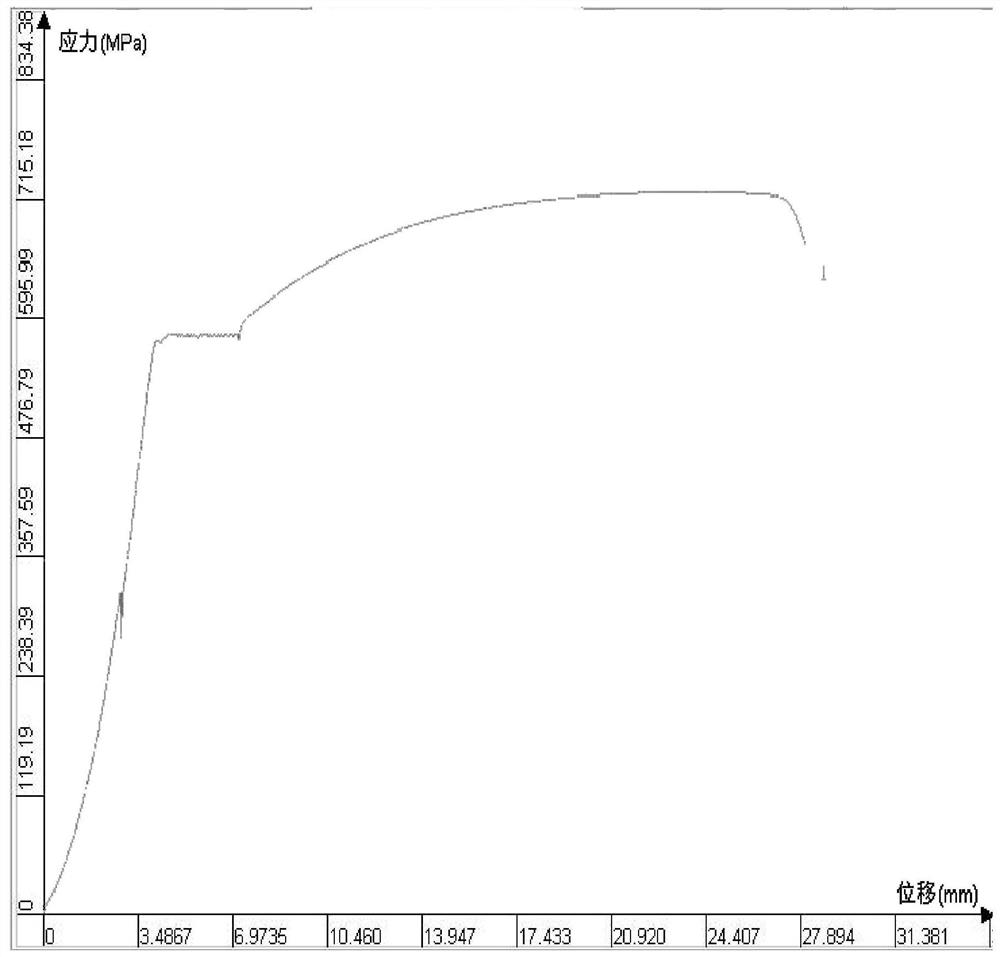

Embodiment 1

[0035] The production process of the HRB500E niobium-titanium microalloy high-strength seismic steel bar of the present invention comprises the following steps:

[0036] Step 1, converter smelting process:

[0037] Add molten iron and scrap steel in a ratio of 9:1, the total amount of molten iron and scrap steel is 80t; blowing for 10min, heating rate is 36℃ / min, control end temperature is 1660℃, 22kg ferrosilicon and 7.4kg silicon are added during the tapping process Manganese alloy and 0.4kg ferroniobium were deoxidized and alloyed, 340L / min air volume was bottom-blown for 3 minutes, then adjusted to 34L / min small air volume, temperature was measured and sampled, 0.82kg ferro-titanium was added after the composition was qualified, and air volume was bottom-blown 40s, stir to make it melt quickly, then adjust to 20L / min small air volume for soft blowing for 6min, the temperature after the furnace is 1568℃, turn off the argon gas, and send it to continuous casting and pouring;...

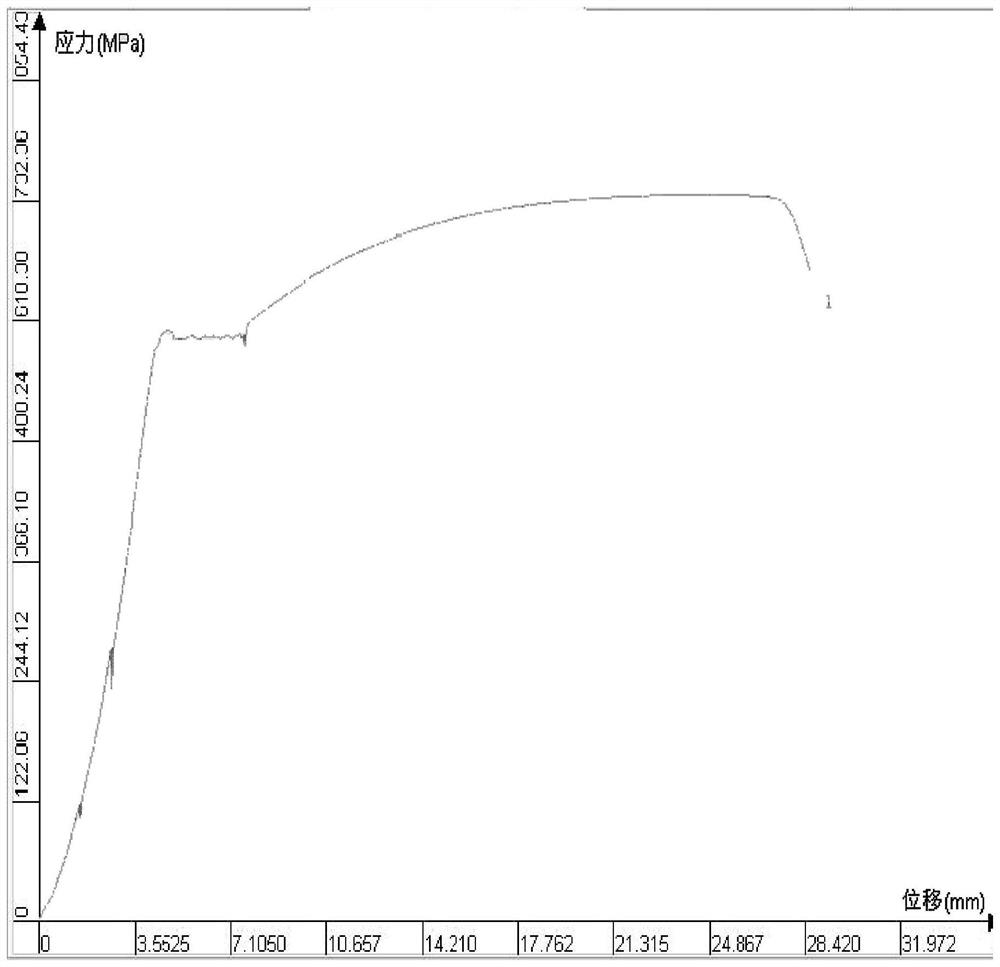

Embodiment 2

[0045] The production process of the HRB500E niobium-titanium microalloy high-strength seismic steel bar of the present invention comprises the following steps:

[0046] Step 1, converter smelting process:

[0047] Add molten iron and scrap steel in a ratio of 9:1, the total amount of molten iron and scrap steel is 80t, blowing for 12min, the heating rate is 31℃ / min, the control end temperature is 1670℃, and 23kg ferrosilicon and 7.6kg silicon are added during the tapping process. Manganese alloy and 0.5kg ferroniobium were deoxidized and alloyed, 360L / min air volume was blown at the bottom for 4 minutes, then a small air volume of 37L / min was adjusted, temperature was measured and sampled, 0.85kg ferrotitanium was added after the composition was qualified, and the air volume was blown at the bottom for 45s , stir to make it melt quickly, then adjust to a small gas volume of 18L / min for soft blowing for 7min, the temperature after the furnace is 1575℃, turn off the argon gas, ...

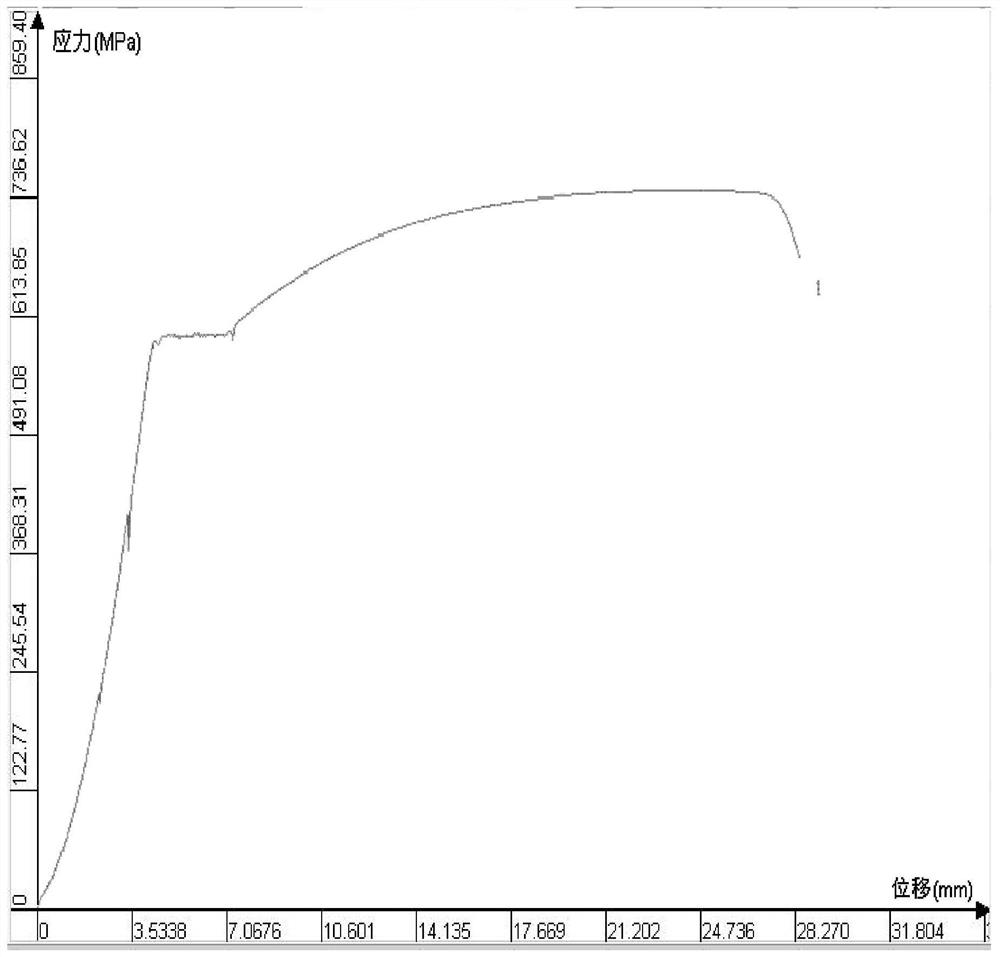

Embodiment 3

[0054] The HRB500E niobium-titanium microalloy high-strength earthquake-resistant steel bar production process of the present invention comprises the following steps:

[0055] Step 1, converter smelting process:

[0056] Add molten iron and scrap steel in a ratio of 9:1, the total amount of molten iron and scrap steel is 80t, blow for 10min, the heating rate is 37℃ / min, the control end temperature is 1668℃, and 24kg ferrosilicon and 7.8kg silicon are added during the tapping process. Manganese alloy and 0.6kg ferroniobium were deoxidized and alloyed, 370L / min air volume was blown at the bottom for 5 minutes, then a small air volume of 35L / min was adjusted, temperature measurement and sampling, after the composition was qualified, 0.9kg ferrotitanium was added, and the air volume was blown at the bottom for 50s , stir to make it melt quickly, then adjust to a small gas volume of 20L / min and soft blow for 7min. After the furnace, the temperature is 1570℃, turn off the argon gas,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com