Automatic assembly method for orthotropic plate unit U-shaped ribs

An orthotropic plate, automatic assembly technology, applied to the edge of the workpiece, arc welding equipment, manufacturing tools, etc., to achieve the effects of stable weld quality, high economic and social benefits, and pollution prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

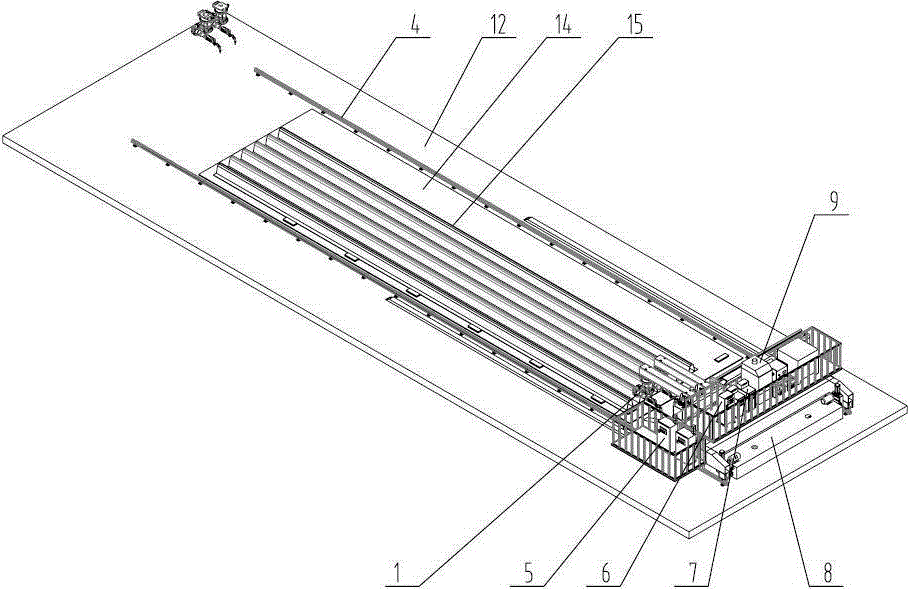

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

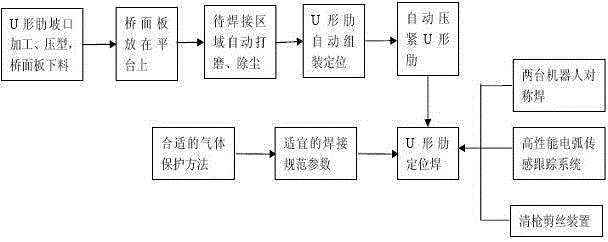

[0030] Such as figure 1 Shown is the implementation flowchart of the method of the present invention. Automatic assembly method of the present invention comprises the following steps:

[0031] (1) U-shaped rib groove processing, pressing, bridge deck blanking:

[0032] After flattening the U-shaped rib with a steel plate, expand the width and length according to the design dimensions of the U-shaped rib and reserve a certain amount of processing for blanking, milling on both sides of the steel plate and processing the groove of the fillet weld (to ensure that the fillet weld of the U-shaped rib The groove angle is 50°), and then the steel plate is pressed on the molding machine to form a U-shaped rib 15; the bridge deck 14 is flattened and then unloaded.

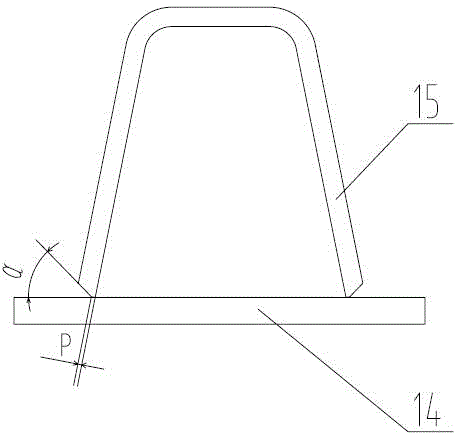

[0033] Such as figure 2 Shown is the groove form of the U-shaped rib fille...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com