An assembly method of shield structure under ultra-low height

A shielding cover and height technology, applied in the fields of magnetic field/electric field shielding, electrical components, metal containers, etc., can solve the problems of difficulty in separating the cover, easy to loosen, etc., to ensure assembly quality, easy maintenance, and reduce the overall design height effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

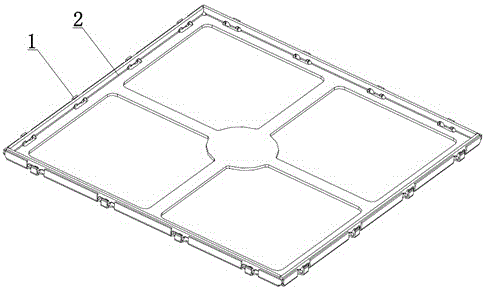

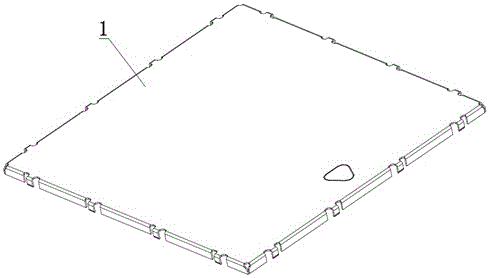

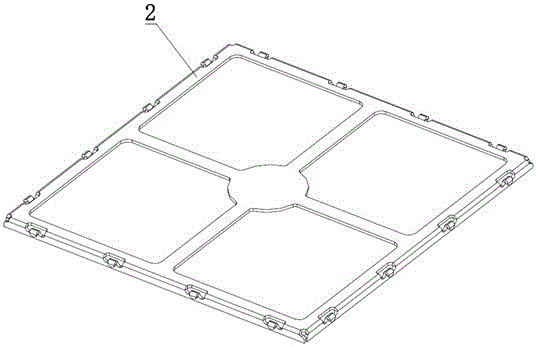

[0027] An assembly method for the structure of the shielding case at an ultra-low height, including a built-in shielding case 2 and an external shielding case 1, the edge of the built-in shielding case 2 is provided with a stacking hook 3, and the edge of the external shielding case 1 is provided with an angle The bending buckle 4, the stacking hook 3 and the angle bending buckle 4 can form a buckle, so that the built-in shielding cover 2 and the external shielding cover 1 can form an ultra-low height assembly structure with a height of 0.5mm through the butt joint of the stacked materials. At the same time, the stacking hook 3 has a U-shaped structure without gaps, and the bending angle of the angle bending buckle 4 is 30°. The two cooperate with each other to form a two-way bending of the shielding cover in the mold, and finally use the external cover Angle bending buckle at the overlapping material of the inner cover to form an inverted buckle to complete the assembly combin...

Embodiment 2

[0029] An assembly method for a shield structure at an ultra-low height, including a built-in shield 2 and an external shield 1, the edge of the built-in shield 2 is provided with overlapping hooks 3, and the stacking hooks 3 are evenly distributed on the built-in shield On each long side of the cover 2, the edge of the external shielding cover 1 is provided with an angle bending buckle 4, and the angle bending buckle 4 is evenly distributed on each long side of the external shielding cover 1, and the stacking hook 3 Corresponding to the positions of the angle bending buckles 4, evenly distributed on each side can make the stamping die design simpler, the modules can be interchanged, easy to maintain, and low in cost.

[0030] The stacking hook 3 and the angle bending buckle 4 can be pressed vertically downward through the bending bullnose of the built-in shielding cover 2 to form a buckle, so that the built-in shielding cover 2 and the external shielding cover 1 can be formed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com