Method for preparing carbon quantum dots by using bagasse as carbon source with chemical oxidation process

A technology of carbon quantum dots and chemical oxidation, applied in chemical instruments and methods, nano-carbon, luminescent materials, etc., can solve the problems of resource waste, human and animal health hazards, nutrient inconsistency, etc., and achieve the effect of mild preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

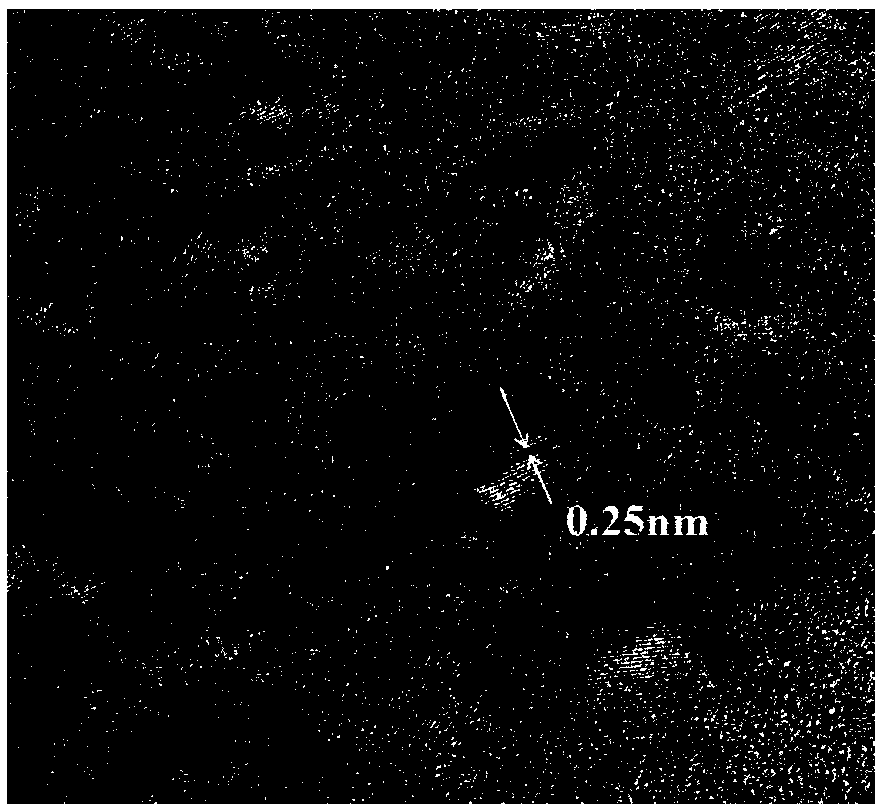

[0022] Embodiment 1: a kind of use bagasse as carbon source to utilize chemical oxidation to prepare carbon quantum dots, comprise the steps:

[0023] (1) Carry out high-temperature carbonization of bagasse at 400° C. to obtain a carbonized black solid, which is ground to obtain a black powder.

[0024] (2) Take 0.2 g of the black powder obtained in step (1) in a 250 mL round bottom flask, add 40 mL of acetic acid (analytical grade) and 20 mL of 30% hydrogen peroxide, ultrasonicate for 50 min, heat to reflux at 100°C for 16 h, and cool.

[0025] (3) Filter the solution obtained in step (2) to remove large particles of impurities and unreacted solid matter. Centrifuge at 4000r / min for 20min, and dialyze the supernatant for 24h. An aqueous solution of carbon quantum dots is obtained.

Embodiment 2

[0026] Embodiment 2: a kind of use bagasse as a carbon source to utilize chemical oxidation to prepare carbon quantum dots, comprising the following steps:

[0027] (1) Carry out high-temperature carbonization of bagasse at 500°C to obtain a carbonized black solid, which is ground to obtain a black powder.

[0028] (2) Take 0.1 g of the black powder prepared in step (1) in a 250 mL round bottom flask, add 20 mL of acetic acid (analytical grade) and 10 mL of 30% hydrogen peroxide, ultrasonicate for 30 min, heat to reflux at 100°C for 10 h, and cool.

[0029] (3) Filter the solution obtained in step (2) to remove large particles of impurities and unreacted solid matter. Centrifuge at 8000r / min for 20min, and dialyze the supernatant for 12h. An aqueous solution of carbon quantum dots is obtained.

Embodiment 3

[0030] Embodiment 3: a kind of use bagasse as a carbon source to utilize chemical oxidation to prepare carbon quantum dots, comprising the following steps:

[0031] (1) Carry out high-temperature carbonization of bagasse at 700°C to obtain a carbonized black solid, which is ground to obtain a black powder.

[0032] (2) Take 0.3 g of the black powder obtained in step (1) in a 250 mL round bottom flask, add 40 mL of acetic acid (analytical grade) and 80 mL of 30% hydrogen peroxide, ultrasonicate for 30 min, heat to reflux at 100 °C for 12 h, and cool.

[0033] (3) Filter the solution obtained in step (2) to remove large particles of impurities and unreacted solid matter. Centrifuge at 4000r / min for 20min, and dialyze the supernatant for 24h. An aqueous solution of carbon quantum dots is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com