LED (Light-Emitting Diode) flip chip and manufacturing method thereof

A technology of flip chip and manufacturing method, which is applied in the direction of electrical components, circuits, semiconductor devices, etc. It can solve the problems of flip chip brightness decrease, chip turn-on voltage rise, contact resistance rise, etc., and achieve low turn-on voltage and contact resistance. , good reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Any feature disclosed in this specification (including any appended claims, abstract and drawings), unless expressly stated otherwise, may be replaced by alternative features which are equivalent or serve a similar purpose. Unless expressly stated otherwise, each feature is only one example of a series of equivalent or similar features.

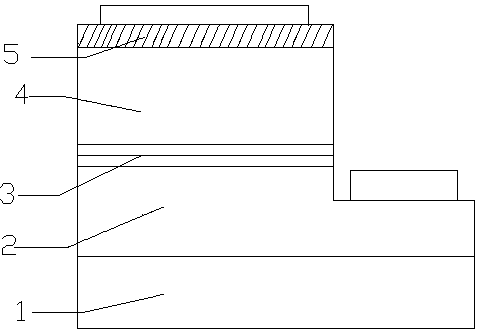

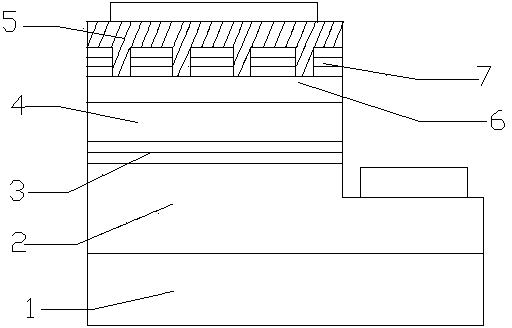

[0029] like figure 2 As shown, an LED flip chip includes a sapphire substrate 1, an LED epitaxial wafer, and an n-type GaN layer 2, a quantum well active region 3, a p-type GaN layer 4, and a metal reflector sequentially arranged on the sapphire substrate 1. layer 5, by dry etching the n-type GaN layer 2 to form an exposed region of the n-type GaN layer, and between the p-type GaN layer 4 and the metal reflection layer 5, a transparent conductive layer 6 and a dielectric reflection layer are sequentially arranged. layer 7; the material of the transparent conductive layer 6 can be indium tin oxide ITO or zinc oxide; the LED epitaxial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com