Etching method for III-V-group compound semiconductor materials

A III-V and compound technology, applied in the field of etching of III-V compound semiconductor materials, can solve the problems of poor surface morphology, poor etching precision, and reduced material properties, so as to achieve low surface damage and improve lines Accuracy, the effect of reducing the processing line width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

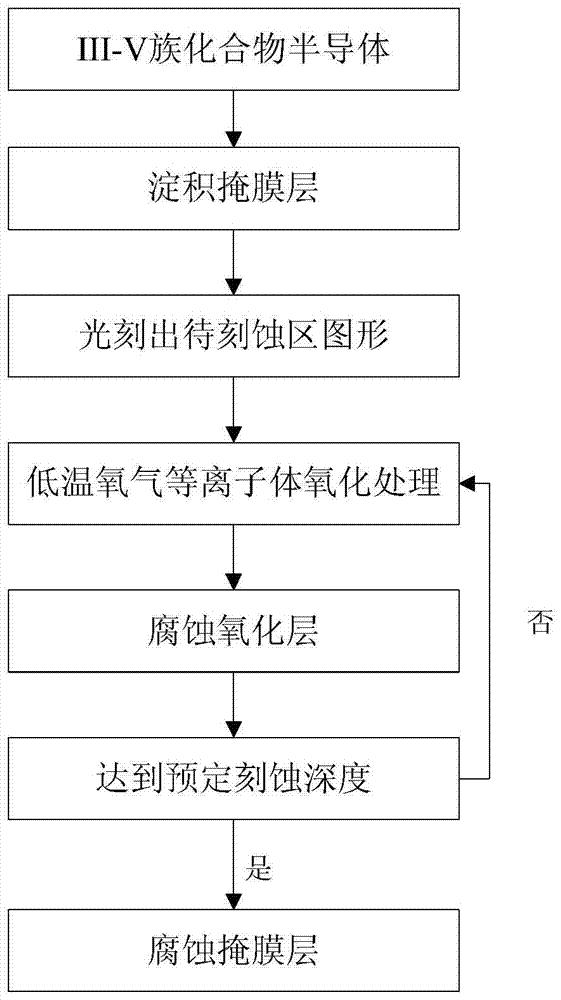

[0026] The etching method of the III-V group compound semiconductor material of the present invention will be described in detail below through specific examples and accompanying drawings.

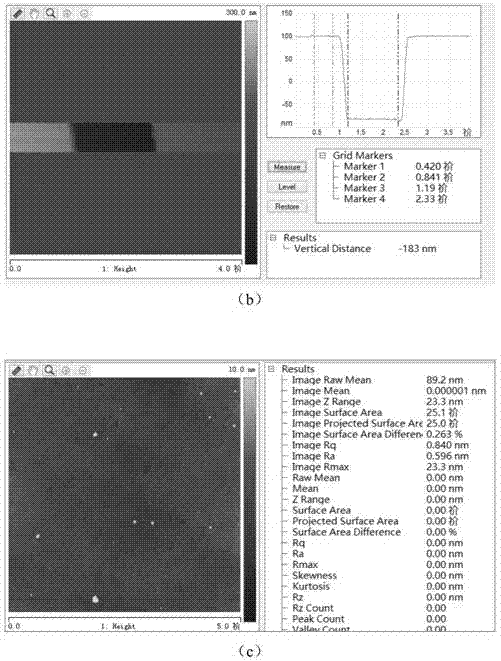

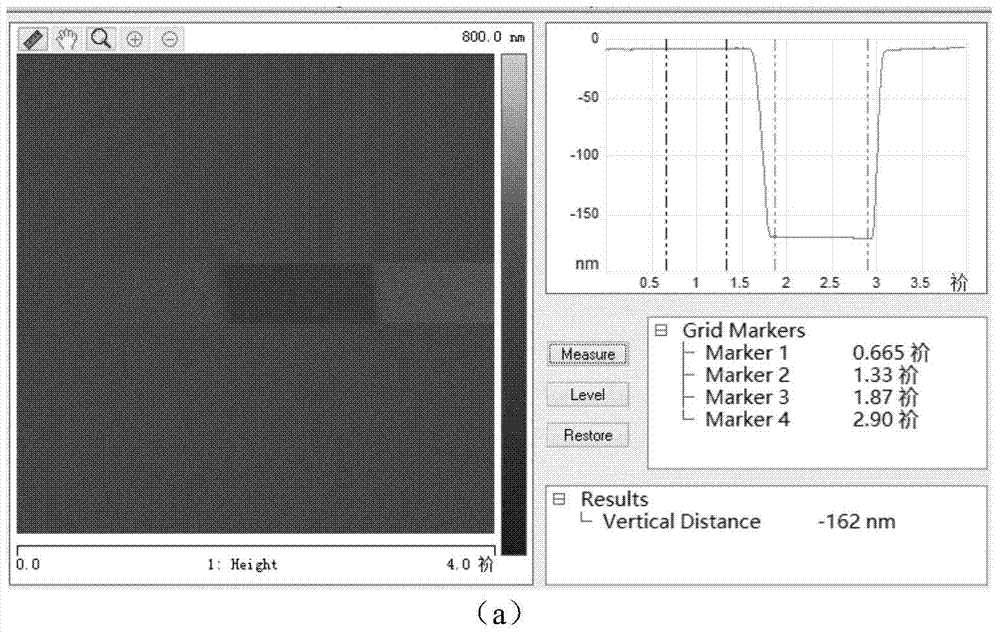

[0027] Taking the AlGaN / GaN heterojunction material as an example, the principle of the present invention to oxidize and wet-etch gallium nitride-based wafers is to perform oxygen plasma treatment on the surface of the AlGaN barrier layer under low temperature conditions, and The surface not protected by Si3N4 will be oxidized by oxygen plasma in AlGaN to form Al X o Y and Ga X o Y And nitrogen oxides, the acidic solution will dissolve the oxide layer without affecting AlGaN, forming a corrosion groove.

[0028] Taking AlGaN / GaN HEMT groove gate etching process as an example, the method will be described in detail below. The gallium nitride-based material groove etching steps include:

[0029] A Si3N4 mask layer with a thickness of 160nm was prepared on the surface of the GaN wafer by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com